Subsea Electrification: Subsea Power Evolves

As subsea power needs evolve, so to must the batteries that provide the power.

Operators of autonomous underwater vehicles (AUVs) need longer survey runs, deeper dives, and lighter batteries, which result in lighter units in the water. Remotely operated vehicle (ROV) teams require electric-powered manipulators, high voltage and high power, and light batteries.

Desires for manned underwater vehicles (MUVs) include safe operations, deeper dives, longer observation times, and lighter units. The oil and gas industry at large demands electronic control, electrical drives, precision and condition based monitoring feedback, and long-life sensors and monitors for their deepwater systems.

In short, innovative subsea applications are getting smarter and going untethered…and untethered subsea operations require batteries that are safe, smart, provide more capacity, deliver more power, are smaller and lighter, longer life, and highly reliable.

For years, most electrical subsea operations were tethered, powered by umbilicals, which are costly, constraining, and require significant lead time. Untethered subsea vehicles used sealed lead acid, which made them heavy and bulky, or batteries contained within 1 atmosphere pressure vessels, which can be expensive and heavy.

Six years ago, Southwest Electronic Energy Corp’s SeaSafe battery brought revolutionary changes to the market. The first commercial pressure-tolerant lithium-ion polymer subsea battery pack known as SeaSafe became available in 2013 after SWE worked on the design in conjunction with Woods Hole Oceanographic Institution. The radically lighter and smaller battery delivered efficiency gains in installation times in addition to vastly improved performance.

About four years later, SWE made available the next generation of the battery pack. The SeaSafe II, available since 2017, incorporated lessons learned, reliability improvements, and American Bureau of Shipping (ABS) Certification. The powerful, pressure tolerant SeaSafe II battery packs are easy to install in a pressure balanced oil-filled (PBOF) container, which is smaller, lighter and lower cost than a pressure vessel. In response to industry demand to eliminate the PBOF container, SWE developed the SeaSafe Direct, which has been available since 2017. SeaSafe Direct is convenient to use as it can be placed directly into the water without requiring the PBOF container.

The SeaSafe II and SeaSafe Direct are powered by large lithium-ion polymer cells that are specially engineered into modules managed by the BMS to provide 30V at 28Ah or other size options. They are able to operate in water depths to 6,000 meters. Multiple SeaSafe batteries can easily be connected together to meet the voltage and power needs of various applications.

These autonomous battery packs are easy to use and are designed for use in subsea vehicles, oceanographic systems, and deepwater oil and gas infrastructure. The batteries have been used in short-duration, high-power demand applications and long-duration, low-power demand situations. Applications include autonomous underwater vehicles for propulsion, control, and instrumentation; in remotely located infrastructure equipment for valve control and pipe shearing; and in oceanography sensing set-ups such as those for monitoring the salinity and temperature of ocean water over a period of time.

Compared to lead acid batteries, SeaSafe battery packs – weigh one-quarter, deliver longer mission times, provide up to four times more energy, and can take thousands of charges. SeaSafe battery packs also function for up to eight times the cycle life of traditional sealed lead acid batteries, which may provide many years of service, and eliminate classic and costly battery failure headaches.

Meeting customer needs

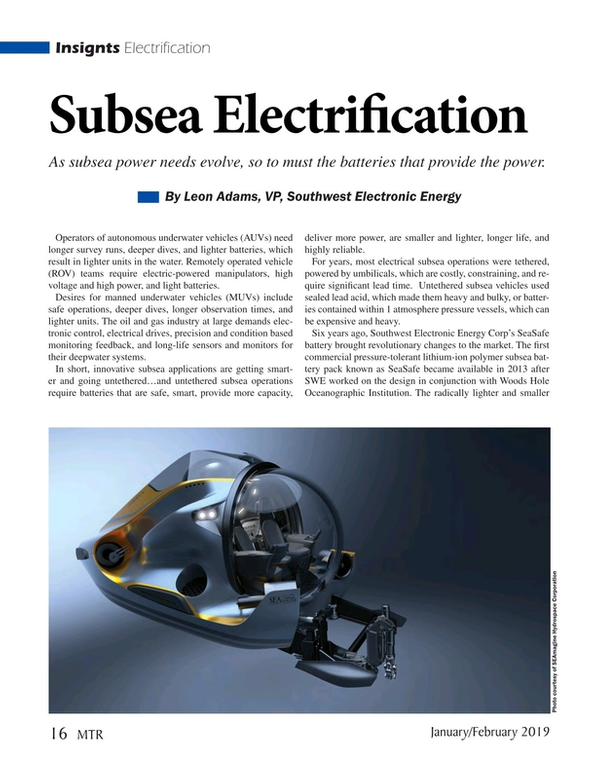

An example user of SWE SeaSafe II is SEAmagine, dedicated to the personal submarines industry since 1995. This private submersibles company has demonstrated the safety, utility, and dependability of its submarines. To support this, SWE SeaSafe employs its patented Battery Management System within every SeaSafe II Battery Module to ensure safety and dependability unsurpassed in the industry. For vehicle assurance, SEAmagine personal submarines are classed A1+ by the American Bureau of Shipping (ABS). As such, SWE SeaSafe II battery modules are ABS Certified in support of this requirement. Further, for SEAmagine, vehicle geometry matters…their innovative Aurora technology is a revolutionary approach to the design of personal submersibles, maximizing the field of view of the spherical cabin and providing an unparalleled unobstructed vista. SWE SeaSafe II Battery modules enable this vista with battery geometry ¼ the size of some competing batteries yet maintains or expands vehicle battery energy capacity. Reliability matters to SEAmagine. SWE SeaSafe II delivers on reliability with up to 8X the life cycle of competitive batteries. SEAmagine modularity and usability needs are met via the configurable battery sizing and subsea pressure tolerant ease of use of SeaSafe II, which simplifies battery configuration and eliminates the weight, size, and cost of a battery pressure vessel. Finally, SEAmagine stands 100% behind all its submersibles and its professional services…as does SWE stand 100% behind SeaSafe II to SEAmagine, delivering them top service, quality, and reliability.

The case for safety

Some are leery of using lithium-ion batteries in a subsea setting. The SeaSafe product line was designed for extreme safety and autonomy. They are fully polyurethane potted in marine-yellow polymer molded cases and completely sealed off from the elements.

Each module includes SWE-patented Battery Management System (BMS) to safeguard the battery pack. The BMS assists with condition-based monitoring programs. The integrated BMS automatically manages and tracks the safety, reliability, charge and discharge of the batteries and reports technical information on demand. Having immediate feedback on the status of the battery system enables one to confidently respond to an emergency requiring battery power.

The batteries function automatically and safely, and the operator does not require experience to use the batteries. After completing a series of tests, ABS has certified the SeaSafe batteries available to configure in various voltage size configurations.

SeaSafe II battery packs are flexible in sizing, as SWE can customize a battery pack solution to customer’s specific product requirements. With several hundred industry-leading customers worldwide, SWE has designed and delivered over thousands of custom battery systems with top service, quality, and reliability.

About the Author

Leon Adams is Vice President – Sales in Lithium and Lithium Ion battery solutions, product definition, and technical customer support. Leon is a member of MTS, SUT, and IEEE. Leon holds a MBA and a BS in Engineering Physics. Leon Adams, the author.

Leon Adams, the author.

Read Subsea Electrification: Subsea Power Evolves in Pdf, Flash or Html5 edition of January 2019 Marine Technology

Other stories from January 2019 issue

Content

- Subsea Electrification: Subsea Power Evolves page: 16

- Contemporary UUV Propulsor Design page: 20

- Unmanned Vehicles: 25 Years of Milestones page: 26

- Subsea: The Future of Unmanned Vehicles page: 34

- The “Disruption” in AUV Trends page: 42