Page 57: of Maritime Logistics Professional Magazine (Q4 2011)

Classification

Read this page in Pdf, Flash or Html5 edition of Q4 2011 Maritime Logistics Professional Magazine

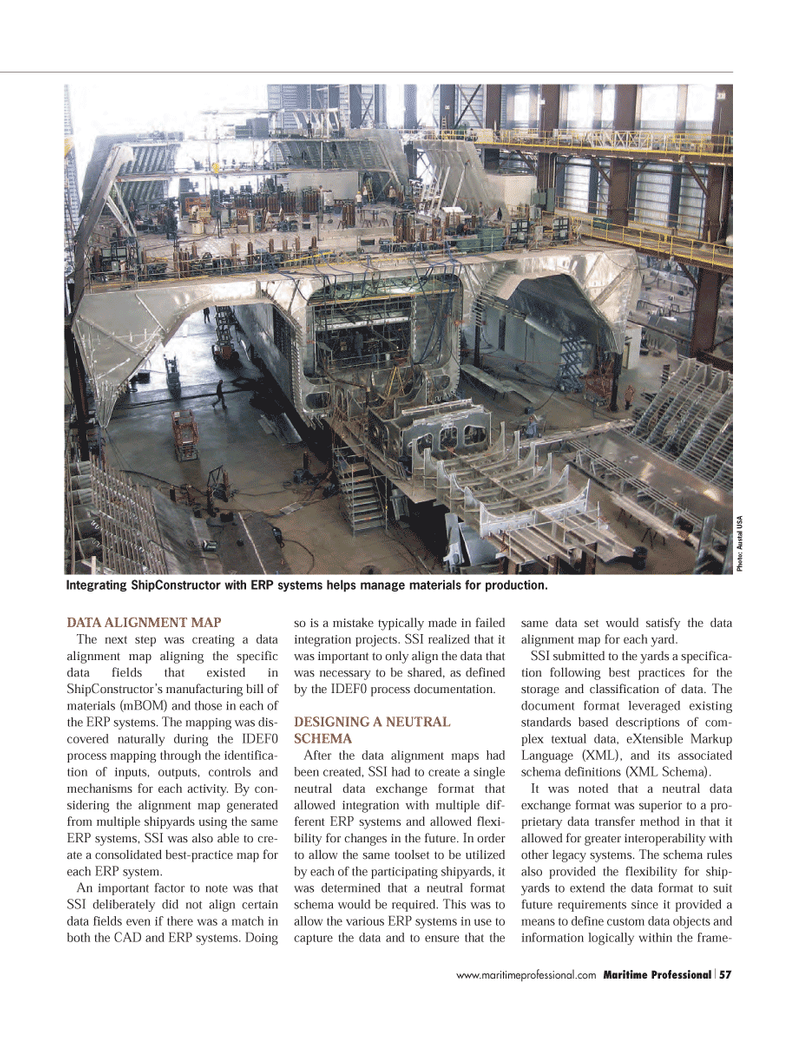

DATA ALIGNMENT MAP The next step was creating a data alignment map aligning the specificdata fields that existed in ShipConstructor?s manufacturing bill of materials (mBOM) and those in each ofthe ERP systems. The mapping was dis- covered naturally during the IDEF0 process mapping through the identifica- tion of inputs, outputs, controls andmechanisms for each activity. By con- sidering the alignment map generatedfrom multiple shipyards using the same ERP systems, SSI was also able to cre- ate a consolidated best-practice map foreach ERP system.An important factor to note was that SSI deliberately did not align certaindata fields even if there was a match in both the CAD and ERP systems. Doingso is a mistake typically made in failed integration projects. SSI realized that it was important to only align the data that was necessary to be shared, as defined by the IDEF0 process documentation. DESIGNING A NEUTRAL SCHEMAAfter the data alignment maps hadbeen created, SSI had to create a singleneutral data exchange format thatallowed integration with multiple dif- ferent ERP systems and allowed flexi- bility for changes in the future. In orderto allow the same toolset to be utilized by each of the participating shipyards, it was determined that a neutral format schema would be required. This was to allow the various ERP systems in use to capture the data and to ensure that thesame data set would satisfy the data alignment map for each yard.SSI submitted to the yards a specifica- tion following best practices for the storage and classification of data. The document format leveraged existing standards based descriptions of com-plex textual data, eXtensible Markup Language (XML), and its associatedschema definitions (XML Schema). It was noted that a neutral data exchange format was superior to a pro- prietary data transfer method in that itallowed for greater interoperability with other legacy systems. The schema rules also provided the flexibility for ship- yards to extend the data format to suit future requirements since it provided a means to define custom data objects and information logically within the frame-www.maritimeprofessional.com Maritime Professional 57 Integrating ShipConstructor with ERP systems helps manage materials for production. Photo: Austal USAMP #4 (50-64):MP Layouts 11/8/2011 2:32 PM Page 57

56

56

58

58