Page 30: of Maritime Logistics Professional Magazine (Q3 2012)

Classification Societies, Quality & Design

Read this page in Pdf, Flash or Html5 edition of Q3 2012 Maritime Logistics Professional Magazine

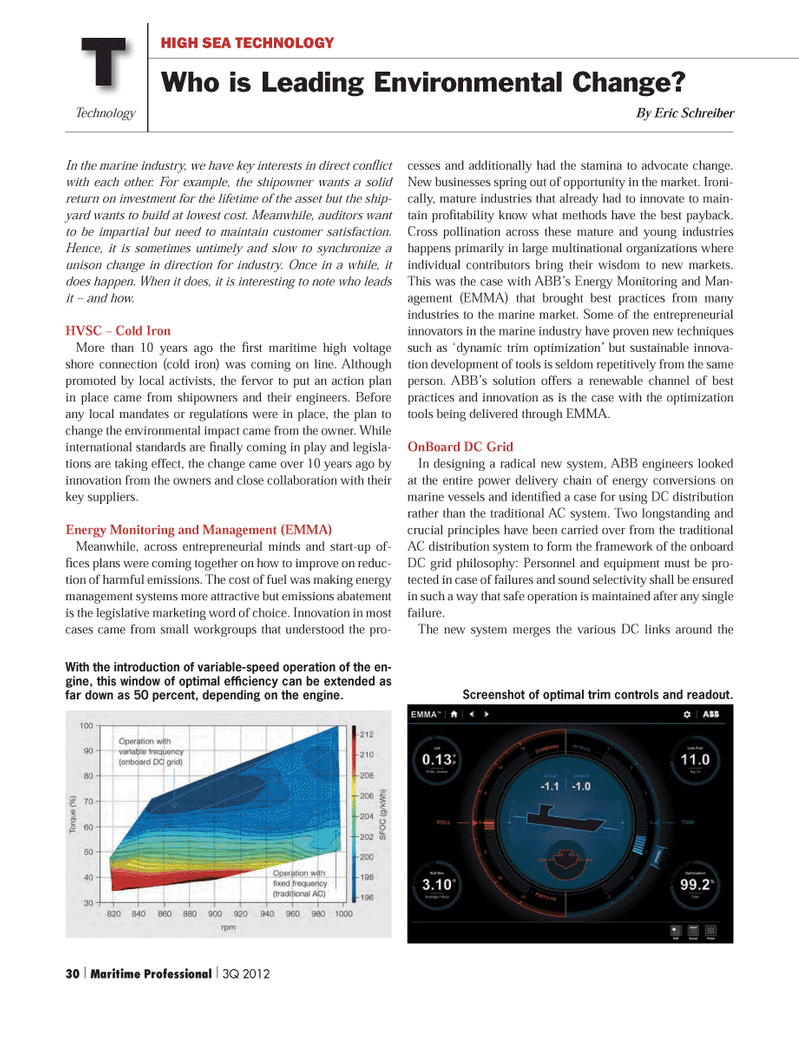

Technology HIGH SEA TECHNOLOGY Who is Leading Environmental Change? TIn the marine industry, we have key interests in direct conß ict with each other. For example, the shipowner wants a solid return on investment for the lifetime of the asset but the ship- yard wants to build at lowest cost. Meanwhile, auditors want to be impartial but need to maintain customer satisfaction. Hence, it is sometimes untimely and slow to synchronize a unison change in direction for industry. Once in a while, it does happen. When it does, it is interesting to note who leads it Ð and how. HVSC ? Cold Iron More than 10 years ago the Þ rst maritime high voltage shore connection (cold iron) was coming on line. Although promoted by local activists, the fervor to put an action plan in place came from shipowners and their engineers. Before any local mandates or regulations were in place, the plan to change the environmental impact came from the owner. While international standards are Þ nally coming in play and legisla- tions are taking effect, the change came over 10 years ago by innovation from the owners and close collaboration with their key suppliers. Energy Monitoring and Management (EMMA) Meanwhile, across entrepreneurial minds and start-up of-Þ ces plans were coming together on how to improve on reduc- tion of harmful emissions. The cost of fuel was making energy management systems more attractive but emissions abatement is the legislative marketing word of choice. Innovation in most cases came from small workgroups that understood the pro- cesses and additionally had the stamina to advocate change. New businesses spring out of opportunity in the market. Ironi- cally, mature industries that already had to innovate to main- tain proÞ tability know what methods have the best payback. Cross pollination across these mature and young industries happens primarily in large multinational organizations where individual contributors bring their wisdom to new markets. This was the case with ABBÕs Energy Monitoring and Man- agement (EMMA) that brought best practices from many industries to the marine market. Some of the entrepreneurial innovators in the marine industry have proven new techniques such as Ôdynamic trim optimizationÕ but sustainable innova- tion development of tools is seldom repetitively from the same person. ABBÕs solution offers a renewable channel of best practices and innovation as is the case with the optimization tools being delivered through EMMA. OnBoard DC GridIn designing a radical new system, ABB engineers looked at the entire power delivery chain of energy conversions on marine vessels and identiÞ ed a case for using DC distribution rather than the traditional AC system. Two longstanding and crucial principles have been carried over from the traditional AC distribution system to form the framework of the onboard DC grid philosophy: Personnel and equipment must be pro-tected in case of failures and sound selectivity shall be ensured in such a way that safe operation is maintained after any single failure. The new system merges the various DC links around the By Eric Schreiber With the introduction of variable-speed operation of the en- gine, this window of optimal efÞ ciency can be extended as far down as 50 percent, depending on the engine. Screenshot of optimal trim controls and readout. 30 | Maritime Professional | 3Q 2012

29

29

31

31