Page 32: of Maritime Logistics Professional Magazine (Q3 2015)

Read this page in Pdf, Flash or Html5 edition of Q3 2015 Maritime Logistics Professional Magazine

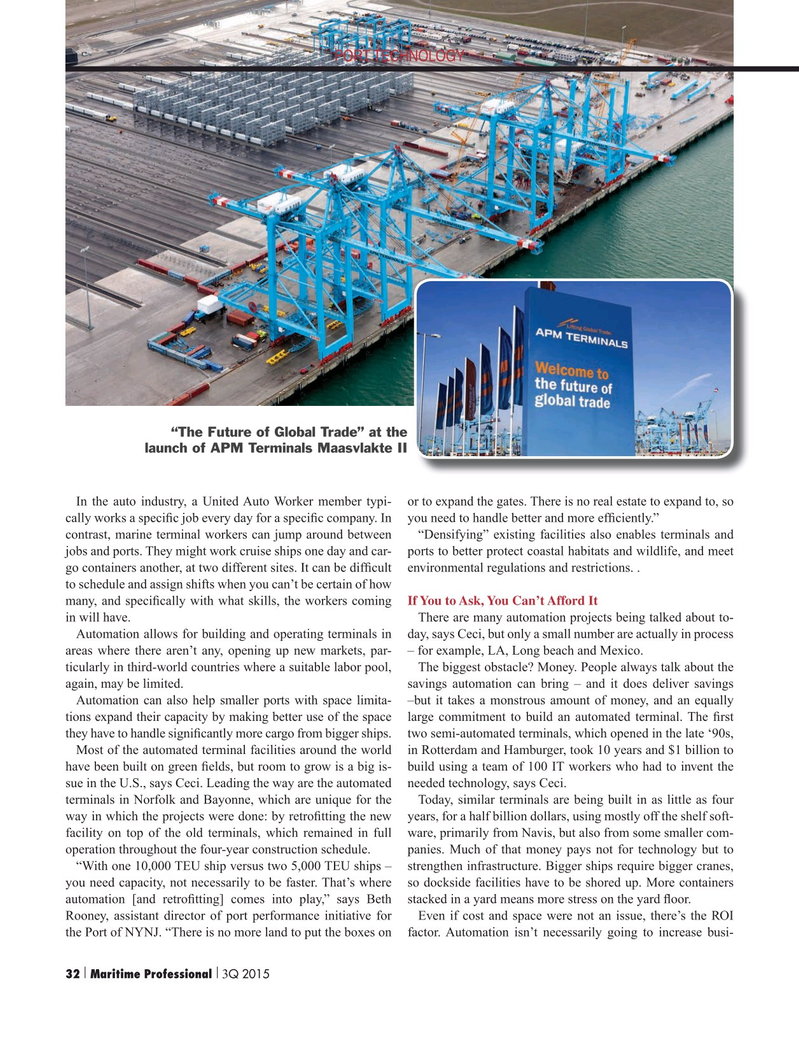

PORT TECHNOLOGY “The Future of Global Trade” at the launch of APM Terminals Maasvlakte II

In the auto industry, a United Auto Worker member typi- or to expand the gates. There is no real estate to expand to, so cally works a speci? c job every day for a speci? c company. In you need to handle better and more ef? ciently.” contrast, marine terminal workers can jump around between “Densifying” existing facilities also enables terminals and jobs and ports. They might work cruise ships one day and car- ports to better protect coastal habitats and wildlife, and meet go containers another, at two different sites. It can be dif? cult environmental regulations and restrictions. . to schedule and assign shifts when you can’t be certain of how many, and speci? cally with what skills, the workers coming If You to Ask, You Can’t Afford It in will have. There are many automation projects being talked about to-

Automation allows for building and operating terminals in day, says Ceci, but only a small number are actually in process areas where there aren’t any, opening up new markets, par- – for example, LA, Long beach and Mexico. ticularly in third-world countries where a suitable labor pool, The biggest obstacle? Money. People always talk about the again, may be limited. savings automation can bring – and it does deliver savings

Automation can also help smaller ports with space limita- –but it takes a monstrous amount of money, and an equally tions expand their capacity by making better use of the space large commitment to build an automated terminal. The ? rst they have to handle signi? cantly more cargo from bigger ships. two semi-automated terminals, which opened in the late ‘90s,

Most of the automated terminal facilities around the world in Rotterdam and Hamburger, took 10 years and $1 billion to have been built on green ? elds, but room to grow is a big is- build using a team of 100 IT workers who had to invent the sue in the U.S., says Ceci. Leading the way are the automated needed technology, says Ceci. terminals in Norfolk and Bayonne, which are unique for the Today, similar terminals are being built in as little as four way in which the projects were done: by retro? tting the new years, for a half billion dollars, using mostly off the shelf soft- facility on top of the old terminals, which remained in full ware, primarily from Navis, but also from some smaller com- operation throughout the four-year construction schedule. panies. Much of that money pays not for technology but to “With one 10,000 TEU ship versus two 5,000 TEU ships – strengthen infrastructure. Bigger ships require bigger cranes, you need capacity, not necessarily to be faster. That’s where so dockside facilities have to be shored up. More containers automation [and retro? tting] comes into play,” says Beth stacked in a yard means more stress on the yard ? oor.

Rooney, assistant director of port performance initiative for Even if cost and space were not an issue, there’s the ROI the Port of NYNJ. “There is no more land to put the boxes on factor. Automation isn’t necessarily going to increase busi- 32 Maritime Professional Q 2015| | 3 18-33 Q3 MP2015.indd 32 9/18/2015 9:53:56 AM

31

31

33

33