Page 42: of Maritime Logistics Professional Magazine (Q3 2016)

Shipbuilding, Repair & Maintenance

Read this page in Pdf, Flash or Html5 edition of Q3 2016 Maritime Logistics Professional Magazine

INTERVIEW training. Over the ? rst year Shell established clear guidelines the tank levels – relying on the alarms – and for being dis- and expectations for incident reports, which allowed us to bet- tracted while helping another crewmember prepare for trans- ter analyze causes and trends. ferring slops. When the alarm sounded the PIC checked the

Most reports do a terri? c job of stating the facts: who, sight gauges and noted the tanks were not full. He silenced the what, when and where. Analyzing these facts to determine alarm, attributing it to a malfunction because false alarms were the “why” and “how” is an area that needs improvement. common. In fact the sight gauges were not reading correctly

For example, I recall receiving more than one report about a because the valves were not fully open, but the PIC chose to barge breakaway that identi? ed the root cause as “the tow- rely on the sight gauges over the alarm system because of the line parted.” This is a description of what happened, not why history of false alarms, (a history that was not known to man- it happened. agement). In addition, the PIC had dutifully read the company

Too often we cite the incorrect actions of a crewmember, or procedures when hired about 18 months before, but had not a failure to act or follow procedure, as the root cause, but fail read them since. When asked to read the portions of the pro- to answer the question about why the error was made. If an in- cedures that applied, he could not explain what he read be- vestigation focuses on blame or fault the true root causes will cause the procedure was ambiguous. The procedure was also not be identi? ed. Root causes lie most often in failures of our generic to the entire ? eet, and some of the steps required by management systems. As an investigator I was introduced to the procedure were not applicable to this vessel. For example, the work of Dr. James Reasons, an expert in human error, who the procedure required the high level alarms be tested prior to famously said, “Human error is a consequence, not a cause.” the transfer, but this test was not possible on this vessel. This

This is a very simple and powerful statement that the mistakes is a classic example of human error caused by weaknesses in made by people are caused by some other factors, most often that company’s management systems. That said it is impor- hidden in our management systems. tant to hold people accountable and recognize that they have a

Let me illustrate with an example. There was a tank over? ll duty to do the right thing and follow procedures. It is equally from a chartered tug due to a tank over? ll while refueling. The important for leaders to be accountable for the systems that report blamed the Person-in-Charge (PIC) for not monitoring their people work under.

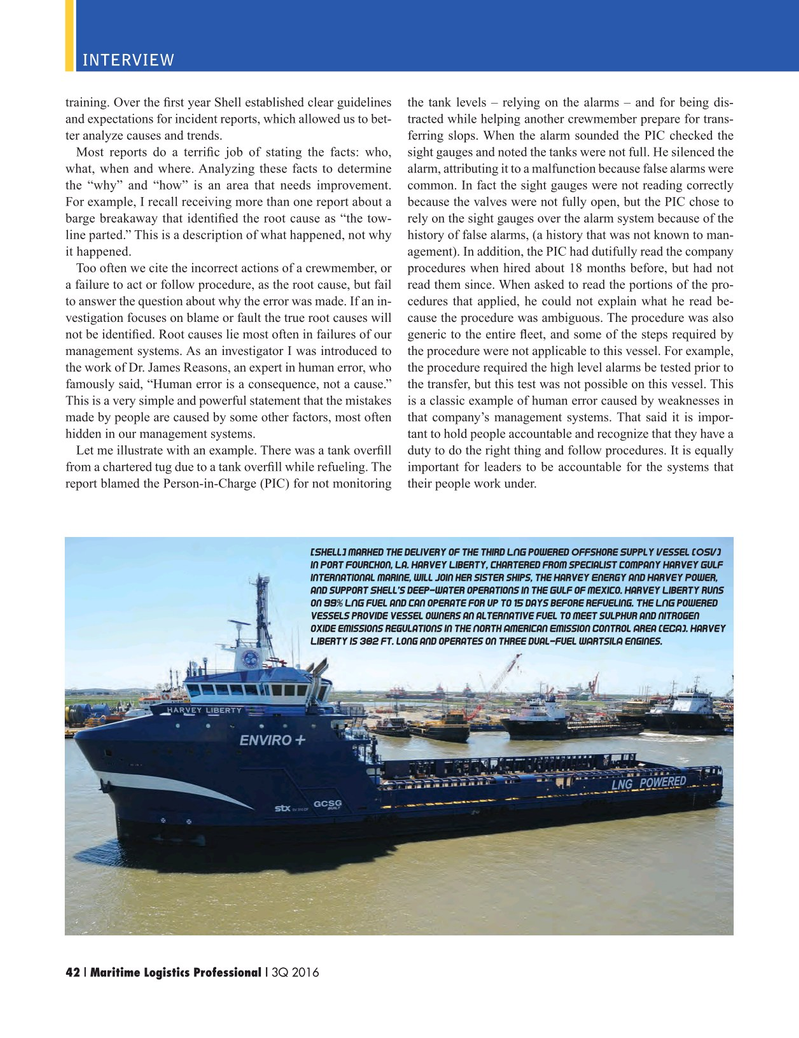

[Shell] marked the delivery of the third LNG powered Offshore Supply Vessel (OSV) in Port Fourchon, La. Harvey Liberty, chartered from specialist company Harvey Gulf

International Marine, will join her sister ships, the Harvey Energy and Harvey Power, and support Shell’s deep-water operations in the Gulf of Mexico. Harvey Liberty runs on 99% LNG fuel and can operate for up to 15 days before refueling. The LNG powered vessels provide vessel owners an alternative fuel to meet sulphur and nitrogen oxide emissions regulations in the North American Emission Control Area (ECA). Harvey

Liberty is 302 ft. long and operates on three dual-fuel WArtsilA engines.

42 | Maritime Logistics Professional | 3Q 2016 34-49 Q3 MP2016.indd 42 8/17/2016 10:33:37 AM

41

41

43

43