Page 56: of Maritime Logistics Professional Magazine (Mar/Apr 2017)

IT & SOFTWARE

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2017 Maritime Logistics Professional Magazine

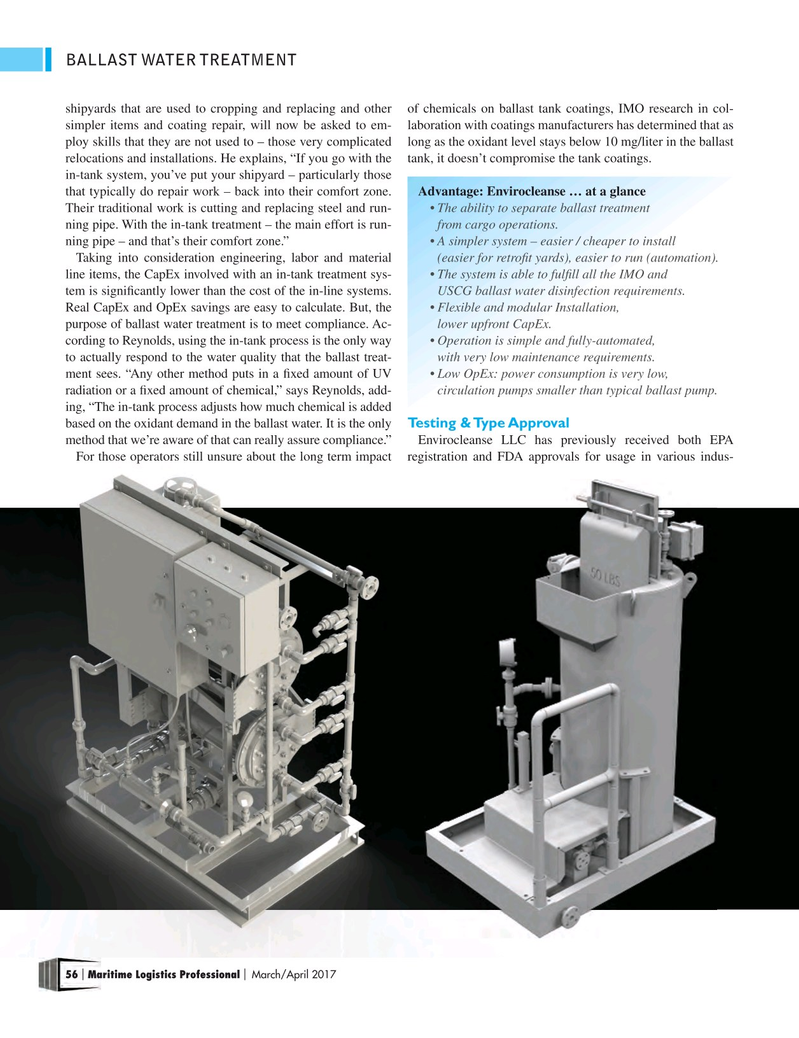

BALLAST WATER TREATMENT shipyards that are used to cropping and replacing and other of chemicals on ballast tank coatings, IMO research in col- simpler items and coating repair, will now be asked to em- laboration with coatings manufacturers has determined that as ploy skills that they are not used to – those very complicated long as the oxidant level stays below 10 mg/liter in the ballast relocations and installations. He explains, “If you go with the tank, it doesn’t compromise the tank coatings.

in-tank system, you’ve put your shipyard – particularly those that typically do repair work – back into their comfort zone. Advantage: Envirocleanse … at a glance

Their traditional work is cutting and replacing steel and run- • The ability to separate ballast treatment ning pipe. With the in-tank treatment – the main effort is run- from cargo operations. ning pipe – and that’s their comfort zone.” • A simpler system – easier / cheaper to install

Taking into consideration engineering, labor and material (easier for retro

55

55

57

57