Page 46: of Maritime Logistics Professional Magazine (Sep/Oct 2017)

CONTAINER PORTS

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2017 Maritime Logistics Professional Magazine

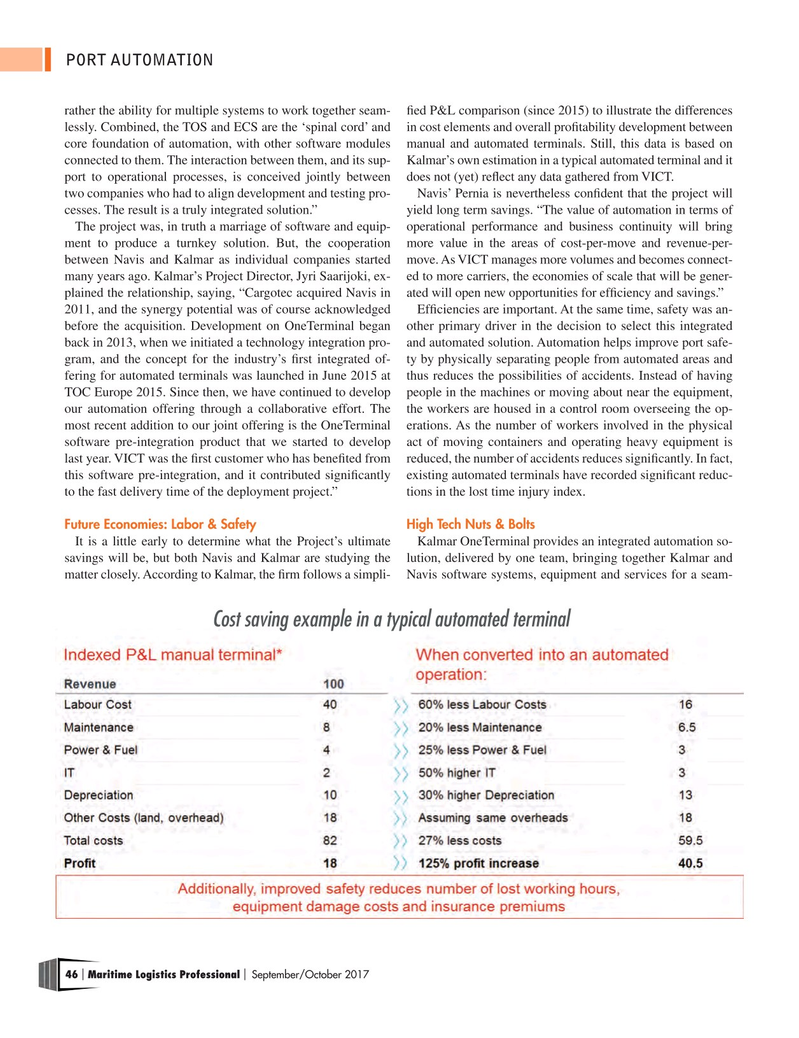

PORT AUTOMATION rather the ability for multiple systems to work together seam- fed P&L comparison (since 2015) to illustrate the differences lessly. Combined, the TOS and ECS are the ‘spinal cord’ and in cost elements and overall proftability development between core foundation of automation, with other software modules manual and automated terminals. Still, this data is based on connected to them. The interaction between them, and its sup- Kalmar’s own estimation in a typical automated terminal and it port to operational processes, is conceived jointly between does not (yet) refect any data gathered from VICT.

two companies who had to align development and testing pro- Navis’ Pernia is nevertheless confdent that the project will cesses. The result is a truly integrated solution.” yield long term savings. “The value of automation in terms of

The project was, in truth a marriage of software and equip- operational performance and business continuity will bring ment to produce a turnkey solution. But, the cooperation more value in the areas of cost-per-move and revenue-per- between Navis and Kalmar as individual companies started move. As VICT manages more volumes and becomes connect- many years ago. Kalmar’s Project Director, Jyri Saarijoki, ex- ed to more carriers, the economies of scale that will be gener- plained the relationship, saying, “Cargotec acquired Navis in ated will open new opportunities for effciency and savings.” 2011, and the synergy potential was of course acknowledged Effciencies are important. At the same time, safety was an- before the acquisition. Development on OneTerminal began other primary driver in the decision to select this integrated back in 2013, when we initiated a technology integration pro- and automated solution. Automation helps improve port safe- gram, and the concept for the industry’s frst integrated of- ty by physically separating people from automated areas and fering for automated terminals was launched in June 2015 at thus reduces the possibilities of accidents. Instead of having

TOC Europe 2015. Since then, we have continued to develop people in the machines or moving about near the equipment, our automation offering through a collaborative effort. The the workers are housed in a control room overseeing the op- most recent addition to our joint offering is the OneTerminal erations. As the number of workers involved in the physical software pre-integration product that we started to develop act of moving containers and operating heavy equipment is last year. VICT was the frst customer who has benefted from reduced, the number of accidents reduces signifcantly. In fact, this software pre-integration, and it contributed signifcantly existing automated terminals have recorded signifcant reduc- to the fast delivery time of the deployment project.” tions in the lost time injury index.

Future Economies: Labor & Safety High Tech Nuts & Bolts

It is a little early to determine what the Project’s ultimate Kalmar OneTerminal provides an integrated automation so- savings will be, but both Navis and Kalmar are studying the lution, delivered by one team, bringing together Kalmar and matter closely. According to Kalmar, the frm follows a simpli- Navis software systems, equipment and services for a seam-

Cost saving example in a typical automated terminal 46 Maritime Logistics Professional September/October 2017 | |

45

45

47

47