Page 52: of Maritime Logistics Professional Magazine (Nov/Dec 2017)

GREEN PORTS

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2017 Maritime Logistics Professional Magazine

CARGO SECURITY cal walk around review involves a very small picture of the ing on a real-time basis that is potentially maintained on the item being reviewed, except that, with PEIR, it isn’t necessary blockchain. This data could be used to update a TMS system to write down the damage because it is now contained in pho- or provide arrival notifcation texts or messages. For container tographic evidence. The PEIR ‘app’ is a very simple intuitive depots, the PEIR interchange could be used to estimate repair app to use. Like other apps, PEIR resides on the one’s Apple or costs on a container or chassis.

Android device which has a camera and internet connectivity. Pricing is as simple as $1 per box surveyed. That cost is for

The truck driver, depot employee or terminal employee will each point in the supply chain that PEIR is employed. PEIR’s take a series of photographs on their Android or Apple device target market, according to Burke, is anyone or any entity that of the shipping container/chassis. Those pictures will be up- is either taking a shipping container into their responsibil- loaded into PEIR’s blockchain infrastructure. ity and liability or passing that shipping container to another

Designed from the ground up to be easily integrated into party. The frm is actively sourcing partners to help beta test other cloud based systems through API technology, PEIR PEIR through the end 2017, with the offcial launch planned security is robust, and its accuracy verifable. When the user for early in January. takes the set of photos for a given inspection, a cryptographic hash is computed. This hash is unique and, for all practical SPOTSEE’S SHOCKLOG purposes, there is a zero chance that the same hash would re- As a global producer of precision impact indicators and re- occur on a different set of photos. And, if a dispute arises, corders, SpotSee has, over time, developed a line of devices

PEIR recomputes the hash for a given inspection (set of pho- that introduce accountability and oversight into the shipping tos) and compares it against the previously recorded hash for and handling stages of the supply chain. Like PEIR, SpotSee that inspection on the internal ledger (which itself has a pub- aims to take the guess work out of what happened to your box licly verifed seal on the blockchain). If the hashes match, then or cargo, leveraging technology to do it. Unlike PEIR, Spot- the set of photos is genuine and not doctored. See’s ShockLog is with you and your cargo over every mile of

That series of pictures is authenticated on the blockchain the journey. But, that’s just the beginning.

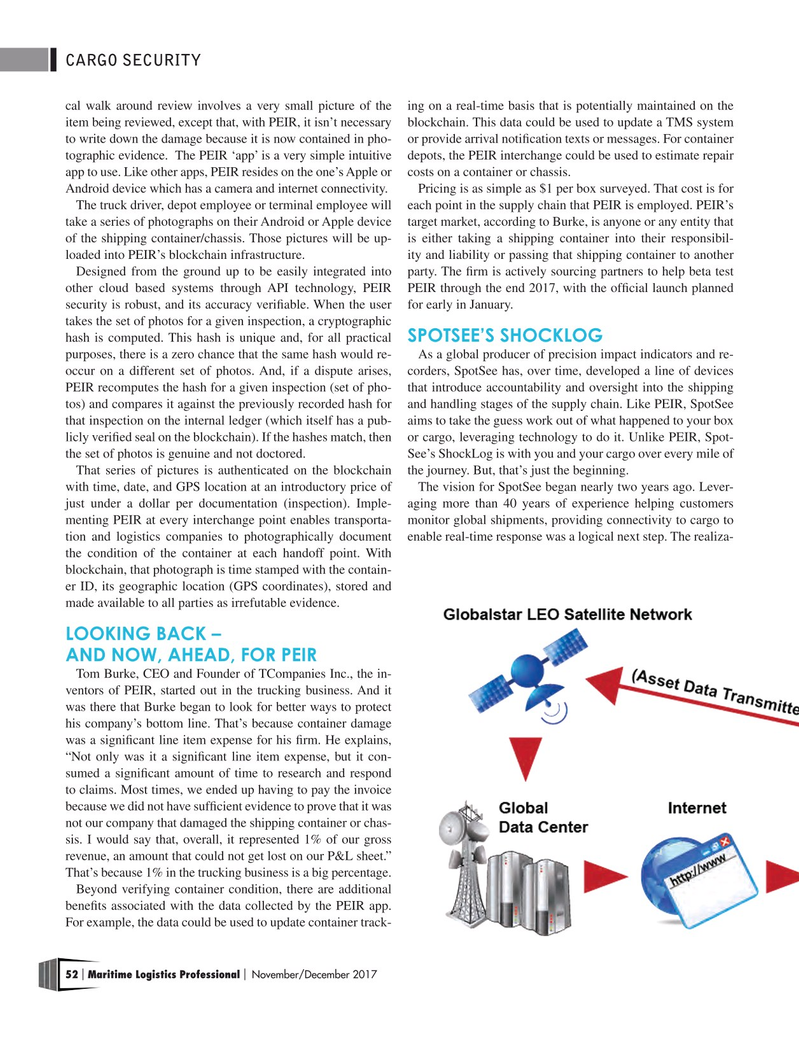

with time, date, and GPS location at an introductory price of The vision for SpotSee began nearly two years ago. Lever- just under a dollar per documentation (inspection). Imple- aging more than 40 years of experience helping customers menting PEIR at every interchange point enables transporta- monitor global shipments, providing connectivity to cargo to tion and logistics companies to photographically document enable real-time response was a logical next step. The realiza- the condition of the container at each handoff point. With blockchain, that photograph is time stamped with the contain- er ID, its geographic location (GPS coordinates), stored and made available to all parties as irrefutable evidence.

LOOKING BACK –

AND NOW, AHEAD, FOR PEIR

Tom Burke, CEO and Founder of TCompanies Inc., the in- ventors of PEIR, started out in the trucking business. And it was there that Burke began to look for better ways to protect his company’s bottom line. That’s because container damage was a signifcant line item expense for his frm. He explains, “Not only was it a signifcant line item expense, but it con- sumed a signifcant amount of time to research and respond to claims. Most times, we ended up having to pay the invoice because we did not have suffcient evidence to prove that it was not our company that damaged the shipping container or chas- sis. I would say that, overall, it represented 1% of our gross revenue, an amount that could not get lost on our P&L sheet.”

That’s because 1% in the trucking business is a big percentage.

Beyond verifying container condition, there are additional benefts associated with the data collected by the PEIR app.

For example, the data could be used to update container track- 52 Maritime Logistics Professional November/December 2017 | |

51

51

53

53