Page 25: of Maritime Logistics Professional Magazine (May/Jun 2018)

Container Ports

Read this page in Pdf, Flash or Html5 edition of May/Jun 2018 Maritime Logistics Professional Magazine

of Peruvian blueberries arrived at PortMiami in March 2014. either be sent north to Philadelphia or returned, Elie recalled.

These frst deliveries, as with all subsequent shipments, re- quired inspections at every step from harvest to pre-cooling In-Transit Treatment Program at a Glance ….

to containerization in specially designed reefers which today Among the dozens of regulation required for the In-Transit must have an array of monitoring devises to assure that crops Cold Treatment Program, these four items stand out in particular: are kept uniformly cold and constantly monitored aboard ship. • All material, labor, and equipment for cold treatment

This detailed information must be reported to APHIS and to performed on a vessel must be provided by the vessel or the destination US port. These initial shipments were checked vessel a gent. An offcial authorized by APHIS monitors, in Panama to make sure everything was cool. And if a prob- manages, and advises in order to ensure that the treatment lem was detected in Panama the container or containers could procedures are followed.

• Refrigeration must be completed in the container, com- partment, or room in which it is begun.

• Fruit that may be cold treated must be safeguarded to pre- vent cross-contamination or mixing with other infested fruit.

• Fruit intended for in-transit cold treatment must be pre- cooled to no more than the highest temperature of the treat- ment sc hedule under which the fruit will be treated prior to be ginning treatment. The in-transit treatment enclosure may not be used for precooling unless an offcial authorized by APHIS approves the loading of the fruit in the treatment enclosure as adequate to allow for fruit pulp temperatures to be tak en prior to beginning treatment. If the fruit is pre- cooled outside the treatment enclosure, an offcial autho- rized by APHIS will take pulp temperatures manually from a sample of the fruit as the fruit is loaded for in-transit cold treatment to verify that precooling was completed. If the pulp temper atures for the sample are 0.28 °C (0.5 °F) or more abo ve the highest temperature of the treatment sched- ule under which the fruit will be treated, the pallet from which the sample was taken will be rejected and returned for additional precooling until the fruit reaches the highest temperature of the treatment schedule under which the fruit will be tr eated. If fruit is precooled in the treatment enclo- sure, or if tr eatment is conducted at a cold treatment facility in the United States, the fruit must be precooled to the high- est temper ature of the treatment schedule under which the fruit will be treated, as verifed by an offcial authorized by

APHIS, prior to beginning treatment.

• The feder al regulations for cold treatment are dozens of sections long and can be found at 7 CFR 305.6 • The fees collected by the carrier from the consignee are: December 28, 2017 to December 27, 2018, $142.00 per container; December 28, 2018 to December 27, 2019, $190.00 per container; and December 28, 2019 onward, $237.00 per container.

Timelines, Deadlines & Progress, too

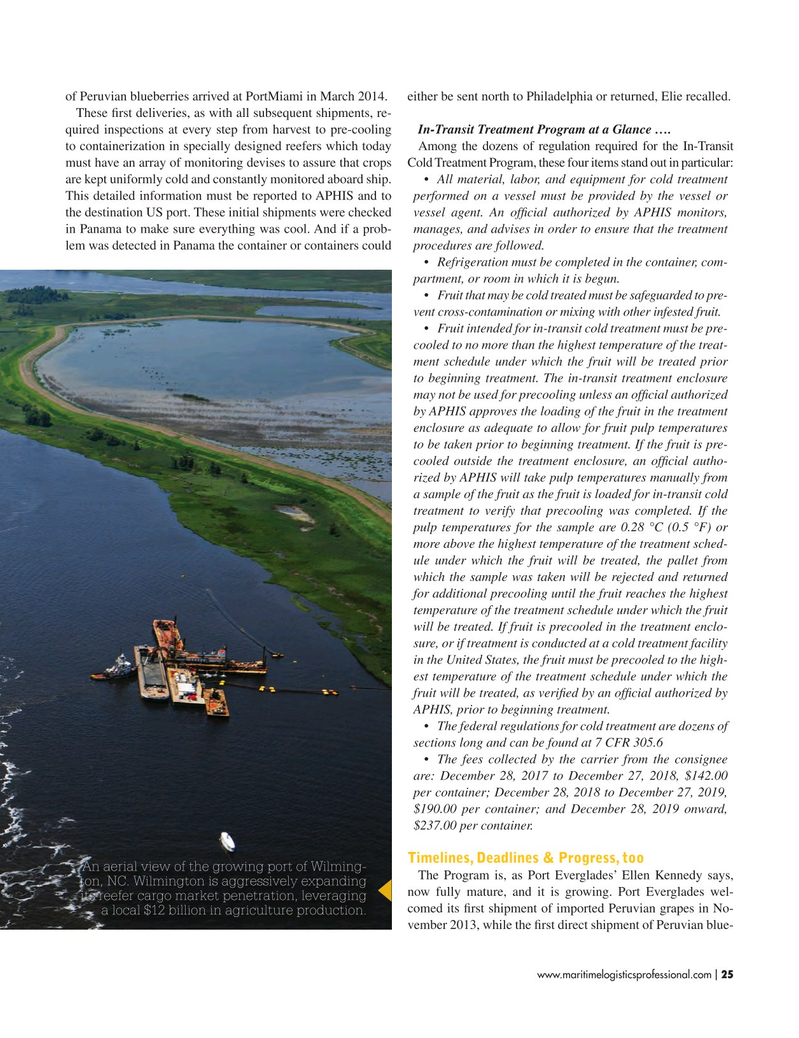

An aerial view of the growing port of Wilming-

The Program is, as Port Everglades’ Ellen Kennedy says, ton, NC. Wilmington is aggressively expanding now fully mature, and it is growing. Port Everglades wel- its reefer cargo market penetration, leveraging comed its frst shipment of imported Peruvian grapes in No- a local $12 billion in agriculture production.

vember 2013, while the frst direct shipment of Peruvian blue- www.maritimelogisticsprofessional.com 25

I

24

24

26

26