Page 40: of Maritime Logistics Professional Magazine (Jul/Aug 2018)

Port Infrastructure & Development

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2018 Maritime Logistics Professional Magazine

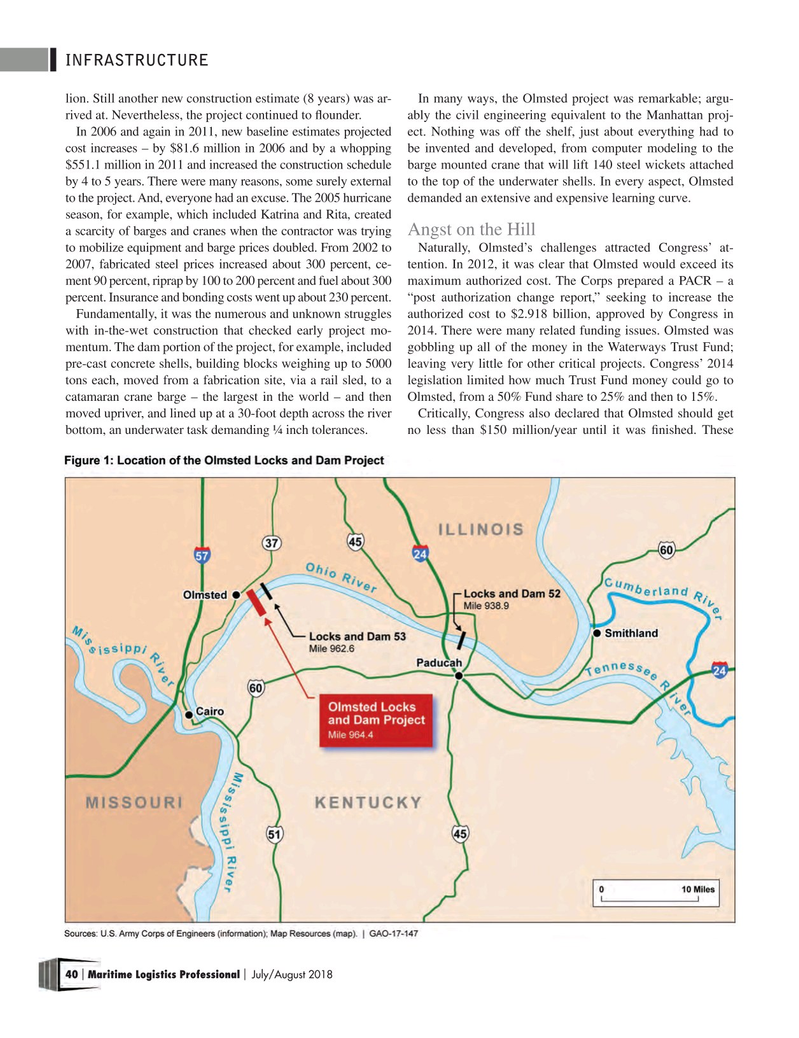

INFRASTRUCTURE lion. Still another new construction estimate (8 years) was ar- In many ways, the Olmsted project was remarkable; argu- rived at. Nevertheless, the project continued to ? ounder. ably the civil engineering equivalent to the Manhattan proj-

In 2006 and again in 2011, new baseline estimates projected ect. Nothing was off the shelf, just about everything had to cost increases – by $81.6 million in 2006 and by a whopping be invented and developed, from computer modeling to the $551.1 million in 2011 and increased the construction schedule barge mounted crane that will lift 140 steel wickets attached by 4 to 5 years. There were many reasons, some surely external to the top of the underwater shells. In every aspect, Olmsted to the project. And, everyone had an excuse. The 2005 hurricane demanded an extensive and expensive learning curve.

season, for example, which included Katrina and Rita, created a scarcity of barges and cranes when the contractor was trying Angst on the Hill to mobilize equipment and barge prices doubled. From 2002 to Naturally, Olmsted’s challenges attracted Congress’ at- 2007, fabricated steel prices increased about 300 percent, ce- tention. In 2012, it was clear that Olmsted would exceed its ment 90 percent, riprap by 100 to 200 percent and fuel about 300 maximum authorized cost. The Corps prepared a PACR – a percent. Insurance and bonding costs went up about 230 percent. “post authorization change report,” seeking to increase the

Fundamentally, it was the numerous and unknown struggles authorized cost to $2.918 billion, approved by Congress in with in-the-wet construction that checked early project mo- 2014. There were many related funding issues. Olmsted was mentum. The dam portion of the project, for example, included gobbling up all of the money in the Waterways Trust Fund; pre-cast concrete shells, building blocks weighing up to 5000 leaving very little for other critical projects. Congress’ 2014 tons each, moved from a fabrication site, via a rail sled, to a legislation limited how much Trust Fund money could go to catamaran crane barge – the largest in the world – and then Olmsted, from a 50% Fund share to 25% and then to 15%.

moved upriver, and lined up at a 30-foot depth across the river Critically, Congress also declared that Olmsted should get bottom, an underwater task demanding ¼ inch tolerances. no less than $150 million/year until it was ? nished. These 40 Maritime Logistics Professional July/August 2018 | | 32-49 MLP JulyAug18.indd 40 32-49 MLP JulyAug18.indd 40 8/7/2018 3:51:08 PM8/7/2018 3:51:08 PM

39

39

41

41