Page 53: of Maritime Logistics Professional Magazine (Sep/Oct 2018)

Liner Shipping & Logistics

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2018 Maritime Logistics Professional Magazine

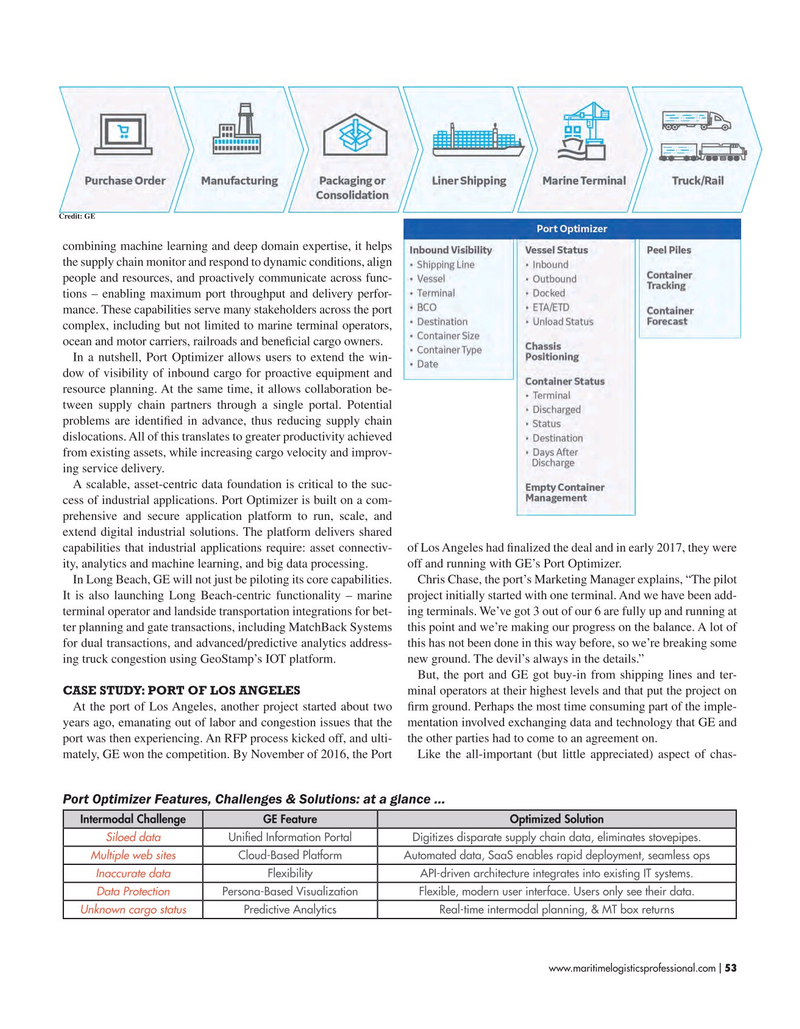

Credit: GE combining machine learning and deep domain expertise, it helps the supply chain monitor and respond to dynamic conditions, align people and resources, and proactively communicate across func- tions – enabling maximum port throughput and delivery perfor- mance. These capabilities serve many stakeholders across the port complex, including but not limited to marine terminal operators, ocean and motor carriers, railroads and benefcial cargo owners.

In a nutshell, Port Optimizer allows users to extend the win- dow of visibility of inbound cargo for proactive equipment and resource planning. At the same time, it allows collaboration be- tween supply chain partners through a single portal. Potential problems are identifed in advance, thus reducing supply chain dislocations. All of this translates to greater productivity achieved from existing assets, while increasing cargo velocity and improv- ing service delivery.

A scalable, asset-centric data foundation is critical to the suc- cess of industrial applications. Port Optimizer is built on a com- prehensive and secure application platform to run, scale, and extend digital industrial solutions. The platform delivers shared capabilities that industrial applications require: asset connectiv- of Los Angeles had fnalized the deal and in early 2017, they were ity, analytics and machine learning, and big data processing. off and running with GE’s Port Optimizer.

In Long Beach, GE will not just be piloting its core capabilities. Chris Chase, the port’s Marketing Manager explains, “The pilot

It is also launching Long Beach-centric functionality – marine project initially started with one terminal. And we have been add- terminal operator and landside transportation integrations for bet- ing terminals. We’ve got 3 out of our 6 are fully up and running at ter planning and gate transactions, including MatchBack Systems this point and we’re making our progress on the balance. A lot of for dual transactions, and advanced/predictive analytics address- this has not been done in this way before, so we’re breaking some ing truck congestion using GeoStamp’s IOT platform. new ground. The devil’s always in the details.”

But, the port and GE got buy-in from shipping lines and ter-

CASE STUDY: PORT OF LOS ANGELES minal operators at their highest levels and that put the project on

At the port of Los Angeles, another project started about two frm ground. Perhaps the most time consuming part of the imple- years ago, emanating out of labor and congestion issues that the mentation involved exchanging data and technology that GE and port was then experiencing. An RFP process kicked off, and ulti- the other parties had to come to an agreement on.

mately, GE won the competition. By November of 2016, the Port Like the all-important (but little appreciated) aspect of chas-

Port Optimizer Features, Challenges & Solutions: at a glance …

Intermodal Challenge GE Feature Optimized Solution

Siloed data Unifed Information Portal Digitizes disparate supply chain data, eliminates stovepipes.

Multiple web sites Cloud-Based Platform Automated data, SaaS enables rapid deployment, seamless ops

Inaccurate data Flexibility API-driven architecture integrates into existing IT systems.

Data Protection Persona-Based Visualization Flexible, modern user interface. Users only see their data.

Unknown cargo status Predictive Analytics Real-time intermodal planning, & MT box returns www.maritimelogisticsprofessional.com 53

I

52

52

54

54