Page 32: of Maritime Logistics Professional Magazine (Nov/Dec 2018)

Regulatory & Environmental Review

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2018 Maritime Logistics Professional Magazine

LNG INFRASTRUCTURE

No Turning Back

A multidisciplinary Rolls-Royce man is helping LNG’s rise on the water and ashore. For LNG, the future is now.

By William Stoichevski

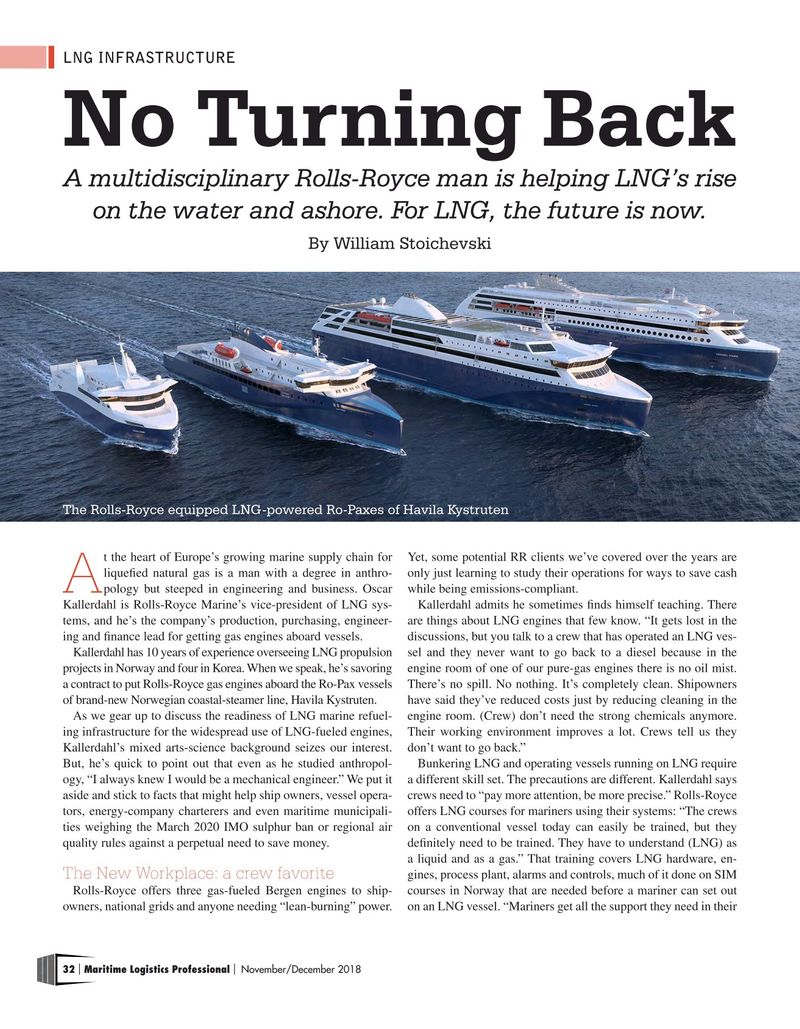

The Rolls-Royce equipped LNG-powered Ro-Paxes of Havila Kystruten t the heart of Europe’s growing marine supply chain for Yet, some potential RR clients we’ve covered over the years are liquefed natural gas is a man with a degree in anthro- only just learning to study their operations for ways to save cash

A pology but steeped in engineering and business. Oscar while being emissions-compliant.

Kallerdahl is Rolls-Royce Marine’s vice-president of LNG sys- Kallerdahl admits he sometimes fnds himself teaching. There tems, and he’s the company’s production, purchasing, engineer- are things about LNG engines that few know. “It gets lost in the ing and fnance lead for getting gas engines aboard vessels. discussions, but you talk to a crew that has operated an LNG ves-

Kallerdahl has 10 years of experience overseeing LNG propulsion sel and they never want to go back to a diesel because in the projects in Norway and four in Korea. When we speak, he’s savoring engine room of one of our pure-gas engines there is no oil mist. a contract to put Rolls-Royce gas engines aboard the Ro-Pax vessels There’s no spill. No nothing. It’s completely clean. Shipowners of brand-new Norwegian coastal-steamer line, Havila Kystruten. have said they’ve reduced costs just by reducing cleaning in the

As we gear up to discuss the readiness of LNG marine refuel- engine room. (Crew) don’t need the strong chemicals anymore. ing infrastructure for the widespread use of LNG-fueled engines, Their working environment improves a lot. Crews tell us they

Kallerdahl’s mixed arts-science background seizes our interest. don’t want to go back.”

But, he’s quick to point out that even as he studied anthropol- Bunkering LNG and operating vessels running on LNG require ogy, “I always knew I would be a mechanical engineer.” We put it a different skill set. The precautions are different. Kallerdahl says aside and stick to facts that might help ship owners, vessel opera- crews need to “pay more attention, be more precise.” Rolls-Royce tors, energy-company charterers and even maritime municipali- offers LNG courses for mariners using their systems: “The crews ties weighing the March 2020 IMO sulphur ban or regional air on a conventional vessel today can easily be trained, but they quality rules against a perpetual need to save money. defnitely need to be trained. They have to understand (LNG) as a liquid and as a gas.” That training covers LNG hardware, en-

The New Workplace: a crew favorite gines, process plant, alarms and controls, much of it done on SIM

Rolls-Royce offers three gas-fueled Bergen engines to ship- courses in Norway that are needed before a mariner can set out owners, national grids and anyone needing “lean-burning” power. on an LNG vessel. “Mariners get all the support they need in their 32 Maritime Logistics Professional November/December 2018 | |

31

31

33

33