Page 20: of Maritime Logistics Professional Magazine (May/Jun 2019)

US and International Navy Ports

Read this page in Pdf, Flash or Html5 edition of May/Jun 2019 Maritime Logistics Professional Magazine

CONTAINER LOGISTICS a crane than meets the eye. Myriad design issues precede every ised, that sort of forethought is also proving to be prescient. “Yes, it’s operation. These include, but are not limited to: all about larger ships. We are in the ‘raising cycle’ right now. Most terminals have at least a few new cranes large enough to attract the

Can dock handle the weight of Can it be jacked up

How high do we go?

newly raised crane? off the dock?

larger ships. Now they are raising their older cranes to increase ca- pacity.” And, it goes without saying, quickly increase capacity.

Which jacking frame How will increased height affect Do you to Jack up to use? Crane stability? off the crane?

Indeed, raising STS cranes is fast becoming the signature proj- ect for ZPMC USA. For his part, Rosenberg isn’t aware of any

Weld or bolt What other upgrades make Will it impact leg inserts? sense at same time? hoisting machinery?

other ?rm that also plays in this sandbox. ZPMC has four propri- etary jacking systems available for crane raise work in the U.S.

As port customers are looking to upgrade local equipment, two that accommodates varying pier loading situations and height in- big issues need to be considered when contemplating what to do creases. Two of the jacking frames load off the dock, and two are next. Speci?cally, as they look for height, the weight of these new designed to jack the crane from its own structure to avoid putting cranes is becoming a factor as existing docks were not built for any extra weight on the pier. Rosenberg explains, “These are pat- the new wheel loads. ented systems; devised and designed by ZPMC.”

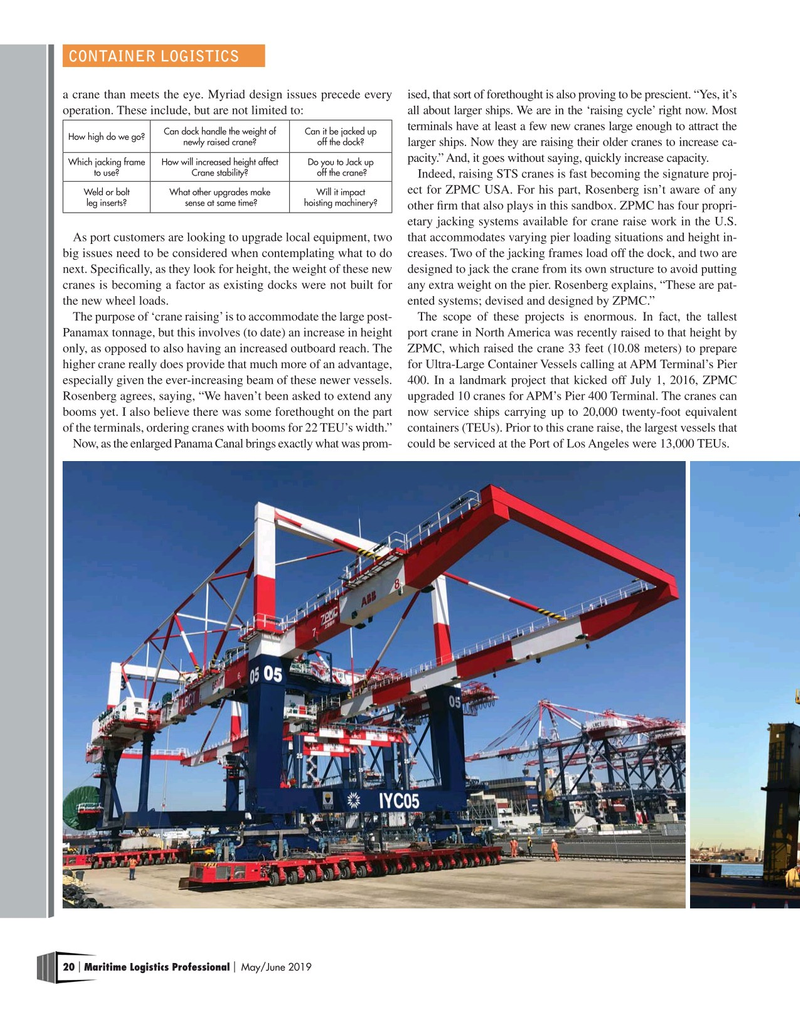

The purpose of ‘crane raising’ is to accommodate the large post- The scope of these projects is enormous. In fact, the tallest

Panamax tonnage, but this involves (to date) an increase in height port crane in North America was recently raised to that height by only, as opposed to also having an increased outboard reach. The ZPMC, which raised the crane 33 feet (10.08 meters) to prepare higher crane really does provide that much more of an advantage, for Ultra-Large Container Vessels calling at APM Terminal’s Pier especially given the ever-increasing beam of these newer vessels. 400. In a landmark project that kicked off July 1, 2016, ZPMC

Rosenberg agrees, saying, “We haven’t been asked to extend any upgraded 10 cranes for APM’s Pier 400 Terminal. The cranes can booms yet. I also believe there was some forethought on the part now service ships carrying up to 20,000 twenty-foot equivalent of the terminals, ordering cranes with booms for 22 TEU’s width.” containers (TEUs). Prior to this crane raise, the largest vessels that

Now, as the enlarged Panama Canal brings exactly what was prom- could be serviced at the Port of Los Angeles were 13,000 TEUs. 20 Maritime Logistics Professional May/June 2019 | |

19

19

21

21