Page 16: of Maritime Reporter Magazine (April 15, 1969)

Read this page in Pdf, Flash or Html5 edition of April 15, 1969 Maritime Reporter Magazine

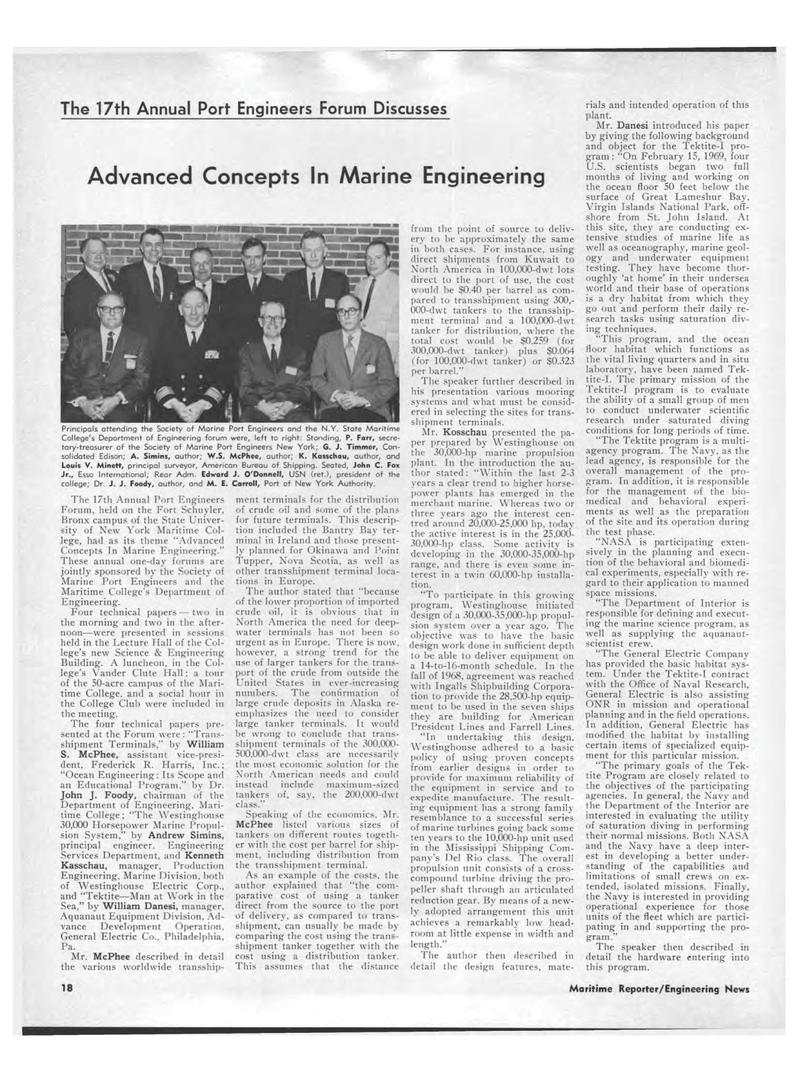

The 17th Annual Port Engineers Forum Discusses Advanced Concepts In Marine Engineering Principals attending the Society of Marine Port Engineers and the N.Y. State Maritime College's Department of Engineering forum were, left to right: Standing, P. Farr, secre-tary-treasurer of the Society of Marine Port Engineers New York; G. J. Timmer, Con-solidated Edison; A. Simins, author; W.S. McPhee, author; K. Kasschau, author, and Louis V. Minett, principal surveyor, American Bureau of Shipping. Seated, John C. Fox Jr., Esso International; Rear Adm. Edward J. O'Donnell, USN (ret.), president of the college; Dr. J. J. Foody, author, and M. E. Carroll, Port of New York Authority. The 17th Annual Port Engineers Forum, held on the Fort Schuyler, Bronx campus of the State Univer-sity of New York Maritime Col-lege, had as its theme "Advanced Concepts In Marine Engineering." These annual one-day forums are jointly sponsored by the Society of Marine Port Engineers and the Maritime College's Department of Engineering. Four technical papers ?- two in the morning and two in the after-noon?were presented in sessions held in the Lecture Hall of the Col-lege's new Science & Engineering Building. A luncheon, in the Col-lege's Vander Clute Hall; a tour of the 50-acre campus of the Mari-time College, and a social hour in the College Club were included in the meeting. The four technical papers pre-sented at the Forum were: "Trans-shipment Terminals," by William S. McPhee, assistant vice-presi-dent, Frederick R. Harris, Inc.; "Ocean Engineering: Its Scope and an Educational Program," by Dr. John J. Foody, chairman of the Department of Engineering. Mari-time College; "The Westinghouse 30,000 Horsepower Marine Propul-sion System," by Andrew Simins, principal engineer. Engineering Services Department, and Kenneth Kasschau, manager, Production Engineering, Marine Division, both of Westinghouse Electric Corp., and "Tektite?Man at Work in the Sea," by William Danesi, manager, Aquanaut Equipment Division, Ad-vance Development Operation, General Electric Co., Philadelphia, Pa. Mr. McPhee described in detail the various worldwide transship-ment terminals for the distribution of crude oil and some of the plans for future terminals. This descrip-tion included the Bantry Bay ter-minal in Ireland and those present-ly planned for Okinawa and Point Tupper, Nova Scotia, as well as other transshipment terminal loca-tions in Europe. The author stated that "because of the lower proportion of imported crude oil, it is obvious that in North America the need for deep-water terminals has not been so urgent as in Europe. There is now, however, a strong trend for the use of larger tankers for the trans-port of the crude from outside the United States in ever-increasing numbers. The confirmation of large crude deposits in Alaska re-emphasizes the need to consider large tanker terminals. It would be wrong to conclude that trans-shipment terminals of the 300.000-500,000-dwt class are necessarily the most economic solution for the North American needs and could instead include maximum-sized tankers of, say, the 200,000-chvt class." Speaking of the economics. Mr. McPhee listed various sizes of tankers on different routes togeth-er with the cost per barrel for ship-ment, including distribution from the transshipment terminal. As an example of the costs, the author explained that "the com-parative cost of using a tanker direct from the source to the port of delivery, as compared to trans-shipment, can usually be made by comparing the cost using the trans-shipment tanker together with the cost using a distribution tanker. This assumes that the distance from the point of source to deliv-ery to be approximately the same in both cases. For instance, using direct shipments from Kuwait to North America in 100,000-dwt lots direct to the port of use, the cost would be $0.40 per barrel as com-pared to transshipment using 300,-000-dwt tankers to the transship-ment terminal and a 100,000-dwt tanker for distribution, where the total cost would be $0,259 (for 300,000-dwt tanker) plus $0,064 (for 100,000-dwt tanker) or $0,323 per barrel." The speaker further described in his presentation various mooring systems and what must be consid-ered in selecting the sites for trans-shipment terminals. Mr. Kosschau presented the pa-per prepared by Westinghouse on the 30,000-hp marine propulsion plant. In the introduction the au-thor stated: "Within the last 2-3 years a clear trend to higher horse-power plants has emerged in the merchant marine. Whereas two or three years ago the interest cen-tred around 20,000-25,000 hp. today the active interest is in the 25.000-30,000-hp class. Some activitv is developing in the 30,000-35,000-hp range, and there is even some in-terest in a twin 60.000-hp installa-tion. "To participate in this growing program, Westinghouse initiated design of a 30,000-35.000-hp propul-sion system over a year ago. The objective was to have the basic design work done in sufficient depth to be able to deliver equipment on a 14-to-16-month schedule. In the fall of 1968. agreement was reached with Ingalls Shipbuilding Corpora-tion to provide the 28,500-hp equip-ment to be used in the seven ships they are building for American President Lines and Farrell Lines. "In undertaking this design. Westinghouse adhered to a basic policy of using proven concepts from earlier designs in order to provide for maximum reliability of the equipment in service and to expedite manufacture. The result-ing equipment has a strong family resemblance to a successful series of marine turbines going back some ten years to the 10,000-hp unit used in the Mississippi Shipping Com-pany's Del Rio class. The overall propulsion unit consists of a cross-compound turbine driving the pro-peller shaft through an articulated reduction gear. By means of a new-ly adopted arrangement this unit achieves a remarkably low head-room at little expense in width and length." The author then described in detail the design features, mate-rials and intended operation of this plant. Mr. Danesi introduced his paper by giving the following background and object for the Tektite-I pro-gram: "On February 15, 1969, four U.S. scientists began two full months of living and working on the ocean floor 50 feet below the surface of Great Lameshur Bay, Virgin Islands National Park, off-shore from St. John Island. At this site, they are conducting ex-tensive studies of marine life as well as oceanography, marine geol-ogy and underwater equipment testing. They have become thor-oughly 'at home' in their undersea world and their base of operations is a dry habitat from which they go out and perform their daily re-search tasks using saturation div-ing techniques. "This program, and the ocean floor habitat which functions as the vital living quarters and in situ laboratory, have been named Tek-tite-I. The primary mission of the Tektite-I program is to evaluate the ability of a small group of men to conduct underwater scientific research under saturated diving conditions for long periods of time. "The Tektite program is a multi-agency program. The Navy, as the lead agency, is responsible for the overall management of the pro-gram. In addition, it is responsible for the management of the bio-medical and behavioral experi-ments as well as the preparation of the site and its operation during the test phase. "NASA is participating exten-sively in the planning and execu-tion of the behavioral and biomedi-cal experiments, especially with re-gard to their application to manned space missions. "The Department of Interior is responsible for defining and execut-ing the marine science program, as well as supplying the aquanaut-scientist crew. "The General Electric Company has provided the basic habitat sys-tem. Under the Tektite-I contract with the Ofifice of Naval Research, General Electric is also assisting ONR in mission and operational planning and in the field operations. In addition. General Electric has modified the habitat by installing certain items of specialized equip-ment for this particular mission. "The primary goals of the Tek-tite Program are closely related to the objectives of the participating agencies. In general, the Navy and the Department of the Interior are interested in evaluating the utility of saturation diving in performing their normal missions. Both NASA and the Navy have a deep inter-est in developing a better under-standing of the capabilities and limitations of small crews on ex-tended, isolated missions. Finally, the Navy is interested in providing operational experience for those units of the fleet which are partici-pating in and supporting the pro-gram." The speaker then described in detail the hardware entering into this program. 18 Maritime Reporter/Engineering News

15

15

17

17