Page 11: of Maritime Reporter Magazine (May 15, 1969)

Read this page in Pdf, Flash or Html5 edition of May 15, 1969 Maritime Reporter Magazine

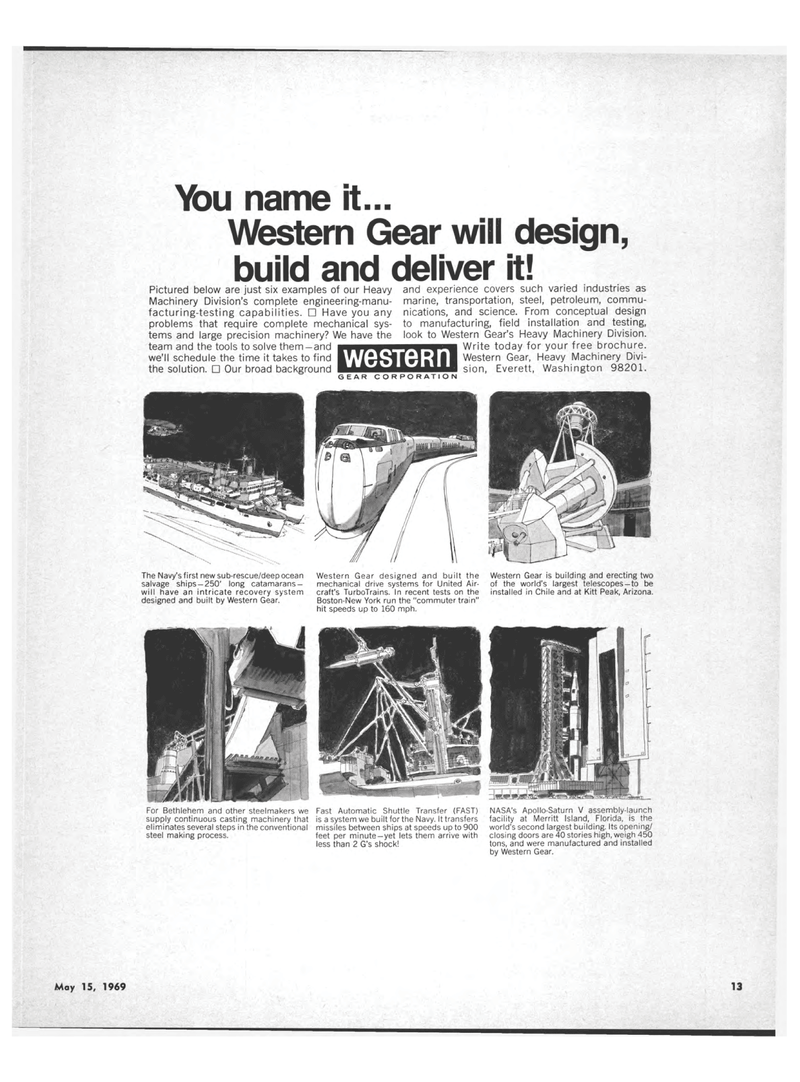

Pictured below are just six examples of our Heavy Machinery Division's complete engineering-manu-facturing-testing capabilities. ? Have you any problems that require complete mechanical sys-tems and large precision machinery? We have the team and the tools to solve them -and we'll schedule the time it takes to find the solution. ? Our broad background wesTeRn GEAR CORPORATION and experience covers such varied industries as marine, transportation, steel, petroleum, commu-nications, and science. From conceptual design to manufacturing, field installation and testing, look to Western Gear's Heavy Machinery Division. Write today for your free brochure. Western Gear, Heavy Machinery Divi-sion, Everett, Washington 98201. You name it... Western Gear will design, build and deliver it! The Navy's first new sub-rescue/deep ocean salvage ships-250' long catamarans-will have an intricate recovery system designed and built by Western Gear. Western Gear designed and built the mechanical drive systems for United Air-craft's TurboTrains. In recent tests on the Boston-New York run the "commuter train" hit speeds up to 160 mph. Western Gear is building and erecting two of the world's largest telescopes-to be installed in Chile and at Kitt Peak, Arizona. For Bethlehem and other steelmakers we supply continuous casting machinery that eliminates several steps in the conventional steel making process. Fast Automatic Shuttle Transfer (FAST) is a system we built for the Navy. It transfers missiles between ships at speeds up to 900 feet per minute-yet lets them arrive with less than 2 G's shock! NASA's Apollo-Saturn V assembly-launch facility at Merritt Island, Florida, is the world's second largest building. Its opening/ closing doors are 40 stories high, weigh 450 tons, and were manufactured and installed by Western Gear. May 15, 1969 13

10

10

12

12