Page 13: of Maritime Reporter Magazine (September 1971)

Read this page in Pdf, Flash or Html5 edition of September 1971 Maritime Reporter Magazine

Why didn't

I think

OF that? J

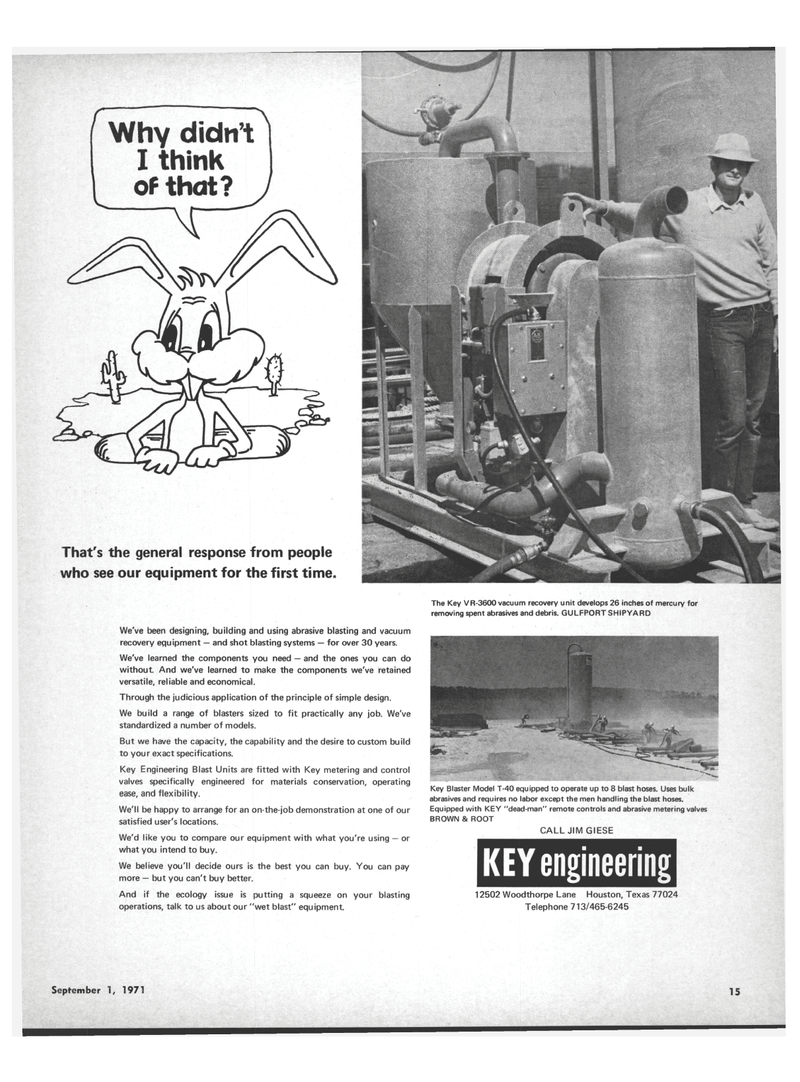

That's the general response from people who see our equipment for the first time.

We've been designing, building and using abrasive blasting and vacuum recovery equipment — and shot blasting systems — for over 30 years.

We've learned the components you need — and the ones you can do without. And we've learned to make the components we've retained versatile, reliable and economical.

Through the judicious application of the principle of simple design.

We build a range of blasters sized to fit practically any job. We've standardized a number of models.

But we have the capacity, the capability and the desire to custom build to your exact specifications.

Key Engineering Blast Units are fitted with Key metering and control valves specifically engineered for materials conservation, operating ease, and flexibility.

We'll be happy to arrange for an on-the-job demonstration at one of our satisfied user's locations.

We'd like you to compare our equipment with what you're using — or what you intend to buy.

We believe you'll decide ours is the best you can buy. You can pay more — but you can't buy better.

And if the ecology issue is putting a squeeze on your blasting operations, talk to us about our "wet blast" equipment.

The Key VR-3600 vacuum recovery unit develops 26 inches of mercury for removing spent abrasives and debris. GULFPORT SHIPYARD

Key Blaster Model T-40 equipped to operate up to 8 blast hoses. Uses bulk abrasives and requires no labor except the men handling the blast hoses.

Equipped with KEY "dead-man" remote controls and abrasive metering valves

BROWN & ROOT

CALL JIM GIESE

KEY engineering 12502 Woodthorpe Lane Houston, Texas 77024

Telephone 713/465-6245

September 1, 1971 15

12

12

14

14