Page 37: of Maritime Reporter Magazine (February 15, 1973)

Read this page in Pdf, Flash or Html5 edition of February 15, 1973 Maritime Reporter Magazine

Nabrico Appoints

David D. Styers bly and wiring of electrical and elec- tronic units, and is built up from plug-in modules specially designed to withstand the severe environmental conditions on board ship. The TOR-

DUCTOR torque transducer, speed pickup and control unit all meet the requirements of regulatory bodies as concerns temperature, vibrations, moisture, etc. No costly calibration is required.

The standard version of the new

ASEA power meter has outputs for instruments and recorders for torque, rpm, and power. In addition, it is available with energy outputs for shp/hr, kw/hr, etc. ASEA can also supply complete installations with outputs for torque, rpm, power, energy, total fuel consumption, and fuel rate.

ASEA power and fuel-rate meters are manufactured and serviced in the

United States by Stal-Laval, Inc., 400 Executive Boulevard, Elmsford,

N.Y. 10523.

James R. Porter

Relocates Offices

James R. Porter, U.S.A. repre- sentative for O.A.R.N. Shipyard,

Genoa, Italy; Globe Engineering

Works Ltd., Capetown, South Af- rica; James Brown & Hamer Ltd.,

Durban, S.A., and Coastal Marine

Service, Port Arthur, Texas, has announced the relocation of its of- fices to 250 Park Avenue, Suite 322,

New York, N.Y. 10017.

David D. Styers

David D. Styers has been ap- pointed controller and assistant secretary for the Nashville Bridge

Company, Nashville, Tenn. The announcement of his promotion was made by William H. Barton

Jr., president of the company. Prior to his advancement, Mr. Styers was in the accounting office and served as assistant to the treasurer. He has been with Nabrico slightly more than a year.

Mr. Styers attended Mississippi

State University and Murray State

University where he pursued a dou- ble major, accounting and business administration, and received his bachelor of science degree in Au- gust 1968. He is a certified public accountant, a member of the Amer- ican Institute of C.P.A.'s, and the

Tennessee Society of C.P.A.'s.

After graduation, Mr. Styers was employed by Genesco, Inc., and served in their internal auditing de- partment. He was controller of

Berland Shoe Company, a division of Genesco, Inc.

ASEA Introduces

New Power Meter

For Propeller Shafts

ASEA recently introduced a new generation of power meters for pro- peller shafts. This equipment is based on the TORDUCTOR® torque trans- ducer, which up to now has been in- stalled on board over 300 ships.

This transducer utilizes the phe- nomenon that the magnetic properties of a propeller shaft change when subjected to torque. No mechanical contact with the propeller shaft is necessary, the TORDUCTOR ring is mounted in two halves around the propeller shaft with a small air-gap between the shaft and the ring. There are no rotating elements or slip rings.

The magnetic field is generated by a series of primary coils, and a voltage proportional to the torque is induced in the secondary coils. Particular at- tention has been paid to the protection of the coils from water and moisture through the use of special insulation.

The propeller shaft speed is re- corded by an electronic pickup mounted on the TORDUCTOR ring.

This pickup operates with a metal band with punched holes, which is fastened around the propeller shaft.

The signals from the torque trans- ducer and speed transducer are trans- mitted to the electronic control unit for signal processing. This control unit is based on ASEA's COMBI-

FLEX modular system for the assem-

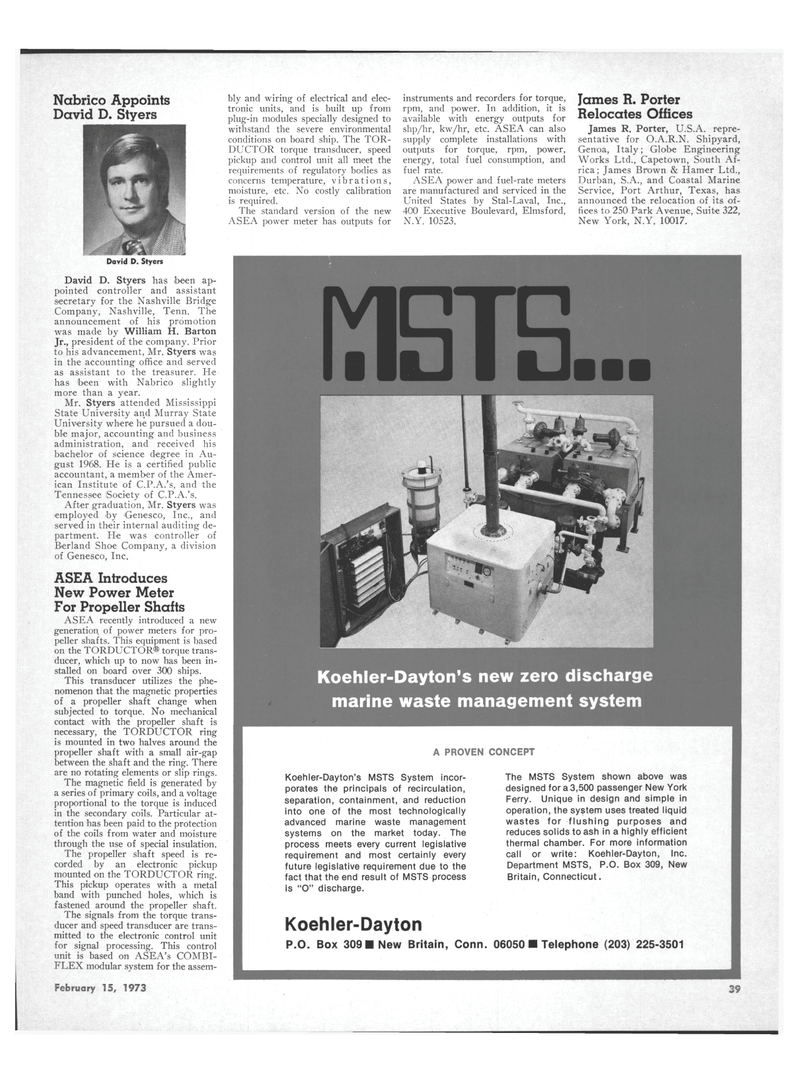

Koehler-Dayton's new zero discharge marine waste management system

A PROVEN CONCEPT

Koehler-Dayton's MSTS System incor- porates the principals of recirculation, separation, containment, and reduction into one of the most technologically advanced marine waste management systems on the market today. The process meets every current legislative requirement and most certainly every future legislative requirement due to the fact that the end result of MSTS process is "O" discharge.

The MSTS System shown above was designed for a 3,500 passenger New York

Ferry. Unique in design and simple in operation, the system uses treated liquid wastes for flushing purposes and reduces solids to ash in a highly efficient thermal chamber. For more information call or write: Koehler-Dayton, Inc.

Department MSTS, P.O. Box 309, New

Britain, Connecticut.

Koehler-Dayton

P.O. Box 309 • New Britain, Conn. 06050 • Telephone (203) 225-3501

February 15, 1973 39

36

36

38

38