Page 5: of Maritime Reporter Magazine (April 15, 1973)

Read this page in Pdf, Flash or Html5 edition of April 15, 1973 Maritime Reporter Magazine

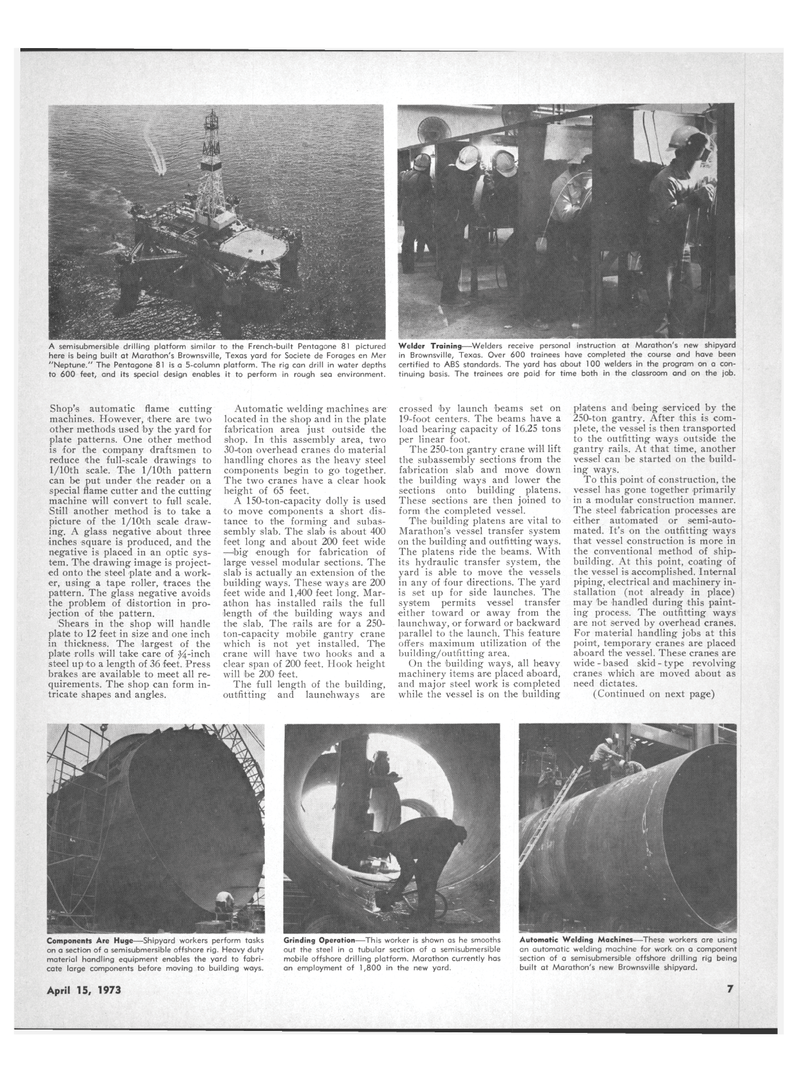

A semisubmersible drilling platform similar to the French-built Pentagone 81 pictured here is being built at Marathon's Brownsville, Texas yard for Societe de Forages en Mer "Neptune." The Pentagone 81 is a 5-column platform. The rig can drill in water depths to 600 feet, and its special design enables it to perform in rough sea environment.

Welder Training—Welders receive personal instruction at Marathon's new shipyard in Brownsville, Texas. Over 600 trainees have completed the course and have been certified to ABS standards. The yard has about 100 welders in the program on a con- tinuing basis. The trainees are paid for time both in the classroom and on the job.

Shop's automatic flame cutting machines. However, there are two other methods used by the yard for plate patterns. One other method is for the company draftsmen to reduce the full-scale drawings to l/10th scale. The l/10th pattern can be put under the reader on a special flame cutter and the cutting machine will convert to full scale.

Still another method is to take a picture of the l/10th scale draw- ing. A glass negative about three inches square is produced, and the negative is placed in an optic sys- tem. The drawing image is project- ed onto the steel plate and a work- er, using a tape roller, traces the pattern. The glass negative avoids the problem of distortion in pro- jection of the pattern.

Shears in the shop will handle plate to 12 feet in size and one inch in thickness. The largest of the plate rolls will take care of j^-inch steel up to a length of 36 feet. Press brakes are available to meet all re- quirements. The shop can form in- tricate shapes and angles.

Automatic welding machines are

located in the shop and in the plate

fabrication area just outside the

shop. In this assembly area, two

30- The two cranes have a clear hook

height of 65 feet.

A 150-ton-capacity dolly is used

to move components a short dis-

tance to the forming and subas-

sembly slab. The slab is about 400

feet long and about 200 feet wide

—'big enough for fabrication of

large vessel modular sections. The

slab is actually an extension of the

building ways. These ways are 200

feet wide and 1,400 feet long. Mar-

athon has installed rails the full

length of the building ways and

the slab. The rails are for a 250-

ton-capacity mobile gantry crane

which is not yet installed. The

crane will have two hooks and a

clear span of 200 feet. Hook height

will be 200 feet.

The full length of the building,

outfitting and launchways are

crossed by launch beams set on

19-foot centers. The beams have a

load bearing capacity of 16.25 tons

per linear foot.

The 250-ton gantry crane will lift

the subassembly sections from the

fabrication slab and move down

the building ways and lower the

sections onto building platens.

These sections are then joined to

form the completed vessel.

The building platens are vital to

Marathon's vessel transfer system

on the building and outfitting ways.

The platens ride the beams. With

its hydraulic transfer system, the

yard is able to move the vessels

in any of four directions. The yard

is set up for side launches. The

system permits vessel transfer

either toward or away from the

launchway, or forward or backward

parallel to the launch. This feature

offers maximum utilization of the

building/outfitting area.

On the building ways, all heavy

machinery items are placed aboard,

and major steel work is completed

while the vessel is on the building

platens and being serviced by the

250-ton gantry. After this is com-

plete, the vessel is then transported

to the outfitting ways outside the

gantry rails. At that time, another

vessel can be started on the build-

ing ways.

To this point of construction, the

vessel has gone together primarily

in a modular construction manner.

The steel fabrication processes are

either automated or semi-auto-

mated. It's on the outfitting ways

that vessel construction is more in

the conventional method of ship-

building. At this point, coating of

the vessel is accomplished. Internal

piping, electrical and machinery in-

stallation (not already in place)

may be handled during this paint-

ing process. The outfitting ways

are not served by overhead cranes.

For material handling jobs at this

point, temporary cranes are placed

aboard the vessel. These cranes are

wide - based skid - type revolving

cranes which are moved about as

need dictates.

(Continued on next page)

Components Are Huge—Shipyard workers perform tasks

on a section of a semisubmersible offshore rig. Heavy duty

material handling equipment enables the yard to fabri-

cate large components before moving to building ways.

Grinding Operation—This worker is shown as he smooths

out the steel in a tubular section of a semisubmersible

mobile offshore drilling platform. Marathon currently has

an employment of 1,800 in the new yard.

Automatic Welding Machines—These workers are using

an automatic welding machine for work on a component

section of a semisubmersible offshore drilling rig being

built at Marathon's new Brownsville shipyard.

April 15, 1973 7

4

4

6

6