Page 15: of Maritime Reporter Magazine (September 15, 1973)

Read this page in Pdf, Flash or Html5 edition of September 15, 1973 Maritime Reporter Magazine

Navy Awards Ingalls $21.3 Million For Work

On Nuclear Submarine

A $21.3-million contract for the overhaul and refueling of the nu- clear-powered submarine USS

Haddo has been awarded by the

Navy to the Ingalls 'Shipbuilding

Division of Litton Industries, Inc. in Pascagoula, Miss.

According to Litton's announce- ment in Beverly Hills, 'Calif., this would be the first nuclear-powered submarine it has been assigned for refueling and the seventh sub- marine for overha'ul.

IMODCO Announces

Offshore Contracts

Totaling $3.5 Million

New contracts, involving four companies, totaling $3.5 million were announced in Los Angeles,

Calif., by IMODCO, Inc.

President Robert C. Houser said these included offshore marine ter- minal systems for Yacimientos Pe- troliiferos Fiscales, Argentine Gov- ernment-owned petroleum com- pany; for PEMEX (Petroleos

Mexicanos) ; a design and engi- neering contract for Hess Oil Vir- gin Islands Corp., and wave and current studies for the Government of India's Engineers (India) Ltd.

The YPF contract is for a Single

Point Mooring terminal system to be installed at Caleta Olivia, some 400 miles south of Buenos Aires.

Scheduled to become operational next May, it will be located 8,000 feet offshore from a new oil field, with crude to be shipped to the

Rio Plata for refining in tankers of up to 60,000 deadweight tons.

Caleta Olivia is within a few miles of Commodoro Rivadavia.

The contract marks the second to IMODCO from YPF. Mr. Hou- ser pointed out that in the two years the initial IMODCO-design- ed and constructed terminal has been in operation at Puerto Ro- sales, close to Buenos Aires in an area of popular bathing beaches, it has handled more than 700 oil tankers without experiencing a sin- gle break or spillage of any kind.

The PEMEX contract, the sec- ond from IMODCO within a year from the Government-owned oil company, is for a Single Point

Mooring terminal system to be in- stalled offshore from Salina Cruz on Mexico's west coast, 350 miles south of Acapulco. Scheduled for completion and installation by next

February, it will serve as a storage depot and distribution point with a four-grade capability—for bunker oil, two refined products, plus dirty ballast water. The earlier PEMEX mooring terminal is already in op- eration offshore from Tuxpan, some 100 miles south of Tampico on the Mexican Gulf coast.

The design and engineering con- tract from Hess Oil Virgin Islands

Corp., a subsidiary of Amerada

Hess Corp., looks to an offshore (SALM) marine terminal at St.

Croix, Virgin Islands. Under terms of the award, the stipulated price will be applied to a construc- tion contract if and when a decision is made to proceed. The marine terminal would utilize the Single

Anchor Leg buoy system recently licensed to IMODCO by Esso Re- search and Engineering Co. It would enable Hess Oil to handle supertankers of up to 500,000 dead- weight tons, and thereby eliminate present costly barging operations.

Wave and current studies being undertaken by IMODCO for En- gineers (India) Ltd. is to deter- mine the feasibility of installing marine terminals offshore from

Mangalore on India's southwest coast and in the Gulif of Kutch on the northwest coast.

The Mangalore study is to evalu- ate whether a mooring terminal could be located miles offshore from that location, the site of a recent iron ore discovery some 11 kilometers north of Panambur.

This is an area of frequent mon- soon rains, high winds and heavy seas from mid-May to mid-Sep- tember. Iron in slurry form would be pumped aboard ore carriers along the lines pioneered by

IMODCO off the coast of New

Zealand during the past two years.

The Gulf of Kutch survey will determine the most logical site for the installation of a Single Point

Mooring system incident to the construction of a new refinery in that area by Indian Oil Ltd.

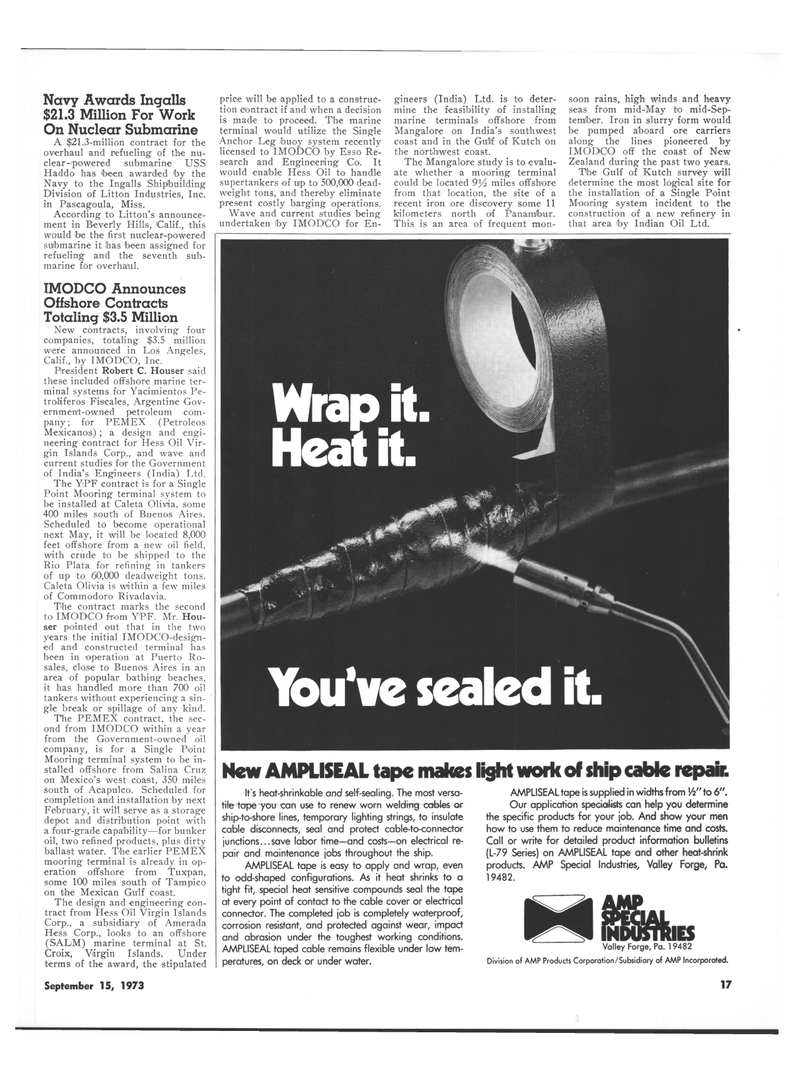

New AMPLISEAL tape makes light work of ship cable repair.

It's heat-shrinkable and self-sealing. The most versa- tile tape you can use to renew worn welding cables or ship-to-shore lines, temporary lighting strings, to insulate cable disconnects, seal and protect cable-to-connector junctions...save labor time—and costs—on electrical re- pair and maintenance jobs throughout the ship.

AMPLISEAL tape is easy to apply and wrap, even to odd-shaped configurations. As it heat shrinks to a tight fit, special heat sensitive compounds seal the tape at every point of contact to the cable cover or electrical connector. The completed job is completely waterproof, corrosion resistant, and protected against wear, impact and abrasion under the toughest working conditions.

AMPLISEAL taped cable remains flexible under low tem- peratures, on deck or under water.

AMPLISEAL tape is supplied in widths from W to 6".

Our application specialists can help you determine the specific products for your job. And show your men how to use them to reduce maintenance time and costs.

Call or write for detailed product information bulletins (L-79 Series) on AMPLISEAL tape and other heat-shrink products. AMP Special Industries, Valley Forge, Pa. 19482.

INI

Valley Forge, Pa. 1 9482

Division of AMP Products Corporation/Subsidiary of AMP Incorporated.

Wrap it Heat it.

You've sealed it

September 15, 1973 17

14

14

16

16