Page 42: of Maritime Reporter Magazine (April 1974)

Read this page in Pdf, Flash or Html5 edition of April 1974 Maritime Reporter Magazine

Syncrolift Elevator Drydock

Expansion Completed At

Singapore Shipbuilding Facility

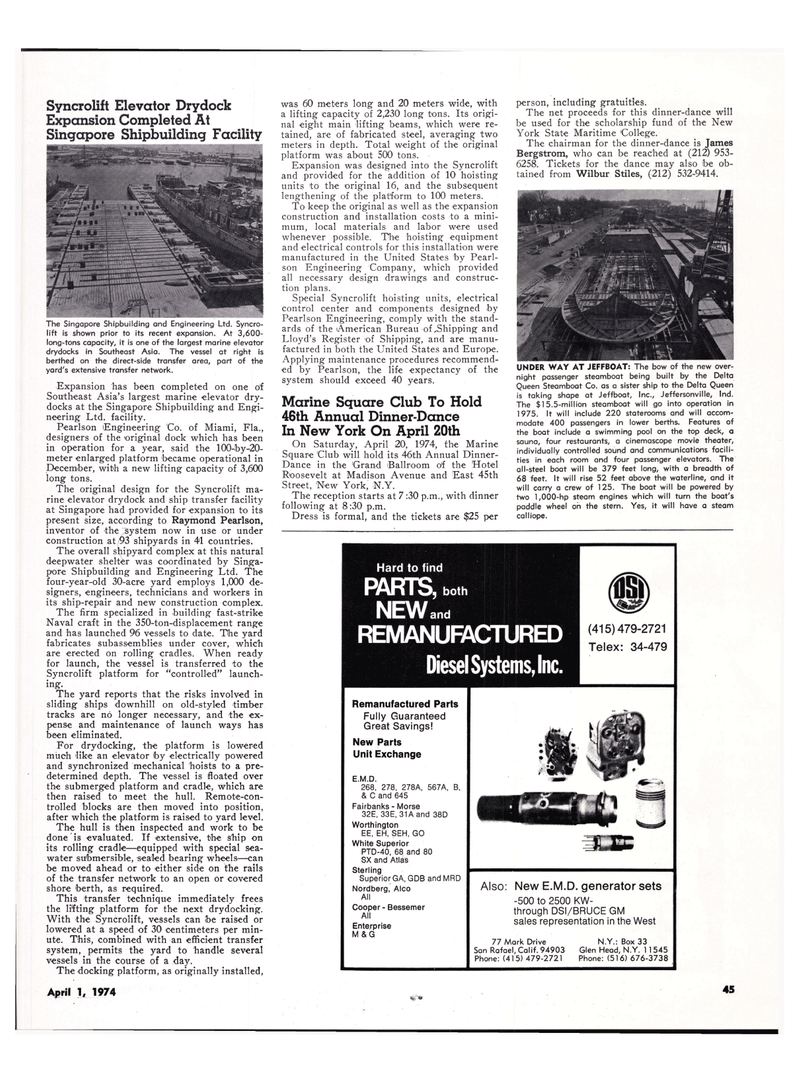

The Singapore Shipbuilding and Engineering Ltd. Syncro- lift is shown prior to its recent expansion. At 3,600- long-tons capacity, it is one of the largest marine elevator drydocks in Southeast Asia. The vessel at right is berthed on the direct-side transfer area, part of the yard's extensive transfer network.

Expansion has been completed on one of

Southeast Asia's largest marine elevator dry- docks at the Singapore Shipbuilding and Engi- neering Ltd. facility.

Pearlson Engineering Co. of Miami, Fla., designers of the original dock which has been in operation for a year, said the 100-by-20- meter enlarged platform became operational in

December, with a new lifting capacity of 3,600 long tons.

The original design for the Syncrolift ma- rine elevator drydock and ship transfer facility at Singapore had provided for expansion to its present size, according to Raymond Pearlson, inventor of -the Tsystem now in use or under construction at 93 shipyards in 41 countries.

The overall shipyard complex at this natural deepwater shelter was coordinated by Singa- pore Shipbuilding and Engineering Ltd. The four-year-old 30-acre yard employs 1,000 de- signers, engineers, technicians and workers in its ship-repair and new construction complex.

The firm specialized in building fast-strike

Naval craft in the 350-ton-displacement range and has launched 96 vessels to date. The yard fabricates subassemblies under cover, which are erected on rolling cradles. When ready for launch, the vessel is transferred to the

Syncrolift platform for "controlled" launch- ing.

The yard reports that the risks involved in sliding ships downhill on old-styled timber tracks are no longer necessary, and the ex- pense and maintenance of launch ways has been eliminated.

For drydocking, the platform is lowered much like an elevator iby electrically powered and synchronized mechanical hoists to a pre- determined depth. The vessel is floated over the submerged platform and cradle, which are then raised to meet the hull. Remote-con- trolled blocks are then moved into position, after which the platform is raised to yard level.

The hull is then inspected and work to be done is evaluated. If extensive, the ship on its rolling cradle—-equipped with special sea- water submersible, sealed bearing wheels—can be moved ahead or to either side on the rails of the transfer network to an open or covered shore berth, as required.

This transfer technique immediately frees the lifting platform for the next drydocking.

With the Syncrolift, vessels can be raised or lowered at a speed of 30 centimeters per min- ute. This, combined with an efficient transfer system, permits the yard to handle several vessels in the course of a day.

The docking platform, as originally installed, was 60 meters long and 20 meters wide, with a lifting capacity of 2,230 long tons. Its origi- nal eight main lifting beams, which were re- tained, are of fabricated steel, averaging two meters in depth. Total weight of the original platform was about 500 tons.

Expansion was designed into the Syncrolift and provided for the addition of 10 hoisting units to the original 16, and the subsequent lengthening of the platform to 100 meters.

To keep the original as well as the expansion construction and installation costs to a mini- mum, local materials and labor were used whenever possible. The hoisting equipment and electrical controls for this installation were manufactured in the United States by Pearl- son Engineering Company, which provided all necessary design drawings and construc- tion plans.

Special Syncrolift hoisting units, electrical control center and components designed by

Pearlson Engineering, comply with the stand- ards of the American Bureau of,Shipping and

Lloyd's Register of Shipping, and are manu- factured in both the United States and Europe.

Applying maintenance procedures recommend- ed by Pearlson, the life expectancy of the system should exceed 40 years.

Marine Square Club To Hold 46th Annual Dinner-Dance

In New York On April 20th

On Saturday, April 20, 1974, the Marine

Square Club will hold its 46th Annual Dinner-

Dance in the Grand Ballroom of the Hotel

Roosevelt at Madison Avenue and East 45th

Street, New York, N.Y.

The reception starts at 7:30 p.m., with dinner following at 8:30 p.m.

Dress is formal, and the tickets are $25 per person, including gratuities.

The net proceeds for this dinner-dance will be used for the scholarship fund of the New

York State Maritime College.

The chairman for the dinner-dance is James

Bergstrom, who can be reached at (212) 953- 6258. Tickets for the dance may also be ob- tained from Wilbur Stiles, (212) 532-9414.

UNDER WAY AT JEFFBOAT: The bow of the new over- night passenger steamboat being built by the Delta

Queen Steamboat Co. as a sister ship to the Delta Queen is taking shape at Jeffboat, Inc., Jeffersonville, Ind.

The $15.5-million steamboat will go into operation in 1975. It will include 220 staterooms and will accom- modate 400 passengers in lower berths. Features of the boat include a swimming pool on the top deck, a sauna, four restaurants, a cinemascope movie theater, individually controlled sound and communications facili- ties in each room and four passenger elevators. The all-steel boat will be 379 feet long, with a breadth of 68 feet. It will rise 52 feet above the waterline, and it will carry a crew of 125. The boat will be powered by two 1,000-hp steam engines which will turn the boat's paddle wheel on the stern. Yes, it will have a steam calliope.

Hard to find

PARTS, both

NEWand

REMANUFACTURED (415) 479-2721 Telex: 34-479

Diesel Systems, Inc.

Remanufactured Parts

Fully Guaranteed

Great Savings!

New Parts

Unit Exchange

E.M.D. 268, 278, 278A, 567A, B, & C and 645

Fairbanks - Morse 32E, 33E, 31A and 38D

Worthington

EE, EH, SEH, GO

White Superior

PTD-40, 68 and 80

SX and Atlas

Sterling

Superior GA, GDB and MRD

Nordberg, Aloo

All

Cooper - Bessemer

All

Enterprise

M & G

Also: New E.M.D. generator sets -500 to 2500 KW- through DSI/BRUCE GM sales representation in the West 77 Mark Drive N.Y.: Box 33

San Rafael, Calif. 94903 Glen Head, N.Y. 1 1 545

Phone: (415) 479-2721 Phone: (516) 676-3738

April 1, 1974 45

41

41

43

43