Page 16: of Maritime Reporter Magazine (November 15, 1977)

Read this page in Pdf, Flash or Html5 edition of November 15, 1977 Maritime Reporter Magazine

Marine Boiler Reliability (continued from page 17) lation the lifetime of particular materials in corrosive flue-gas at- mosphere. Information of this nature can be derived only by experience with the particular material within an environment which closely approximates actual operating conditions. This portion of the R&D effort involved first investigating published data deal- ing with the corrosion of various

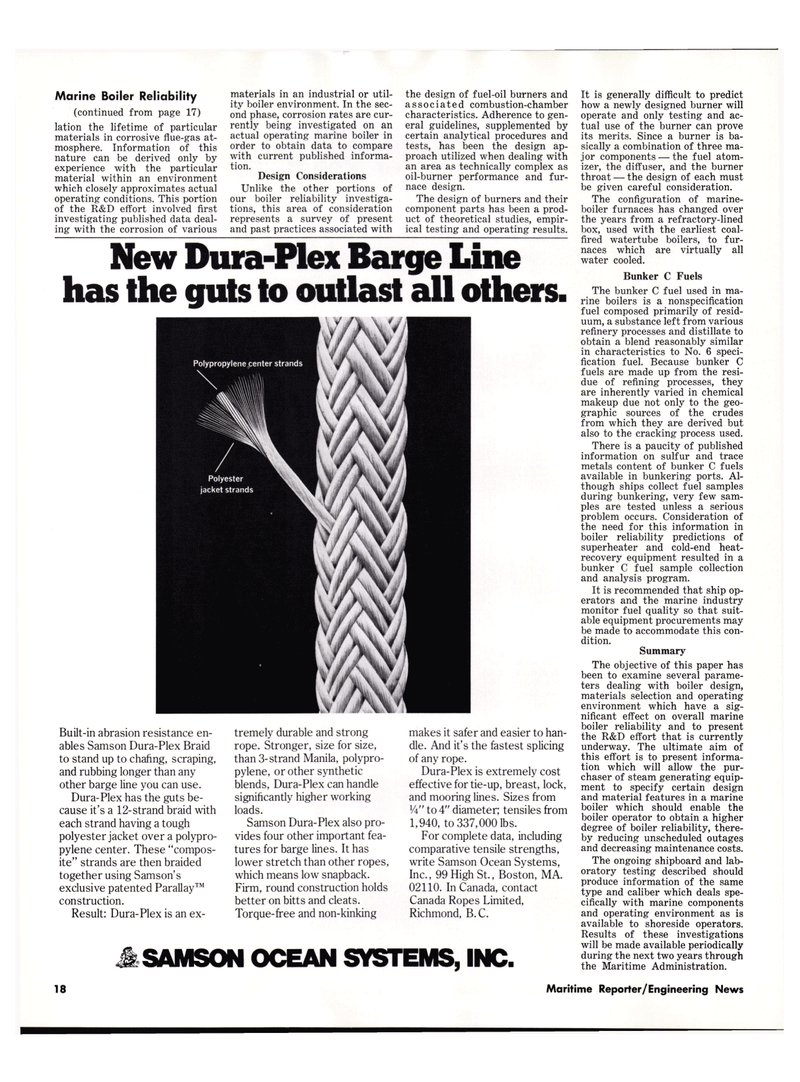

Built-in abrasion resistance en- ables Samson Dura-Plex Braid to stand up to chafing, scraping, and rubbing longer than any other barge line you can use.

Dura-Plex has the guts be- cause it's a 12-strand braid with each strand having a tough polyester jacket over a polypro- pylene center. These "compos- ite" strands are then braided together using Samson's exclusive patented Parallay™ construction.

Result: Dura-Plex is an ex- materials in an industrial or util- ity boiler environment. In the sec- ond phase, corrosion rates are cur- rently being investigated on an actual operating marine boiler in order to obtain data to compare with current published informa- tion.

Design Considerations

Unlike the other portions of our boiler reliability investiga- tions, this area of consideration represents a survey of present and past practices associated with tremely durable and strong rope. Stronger, size for size, than 3-strand Manila, polypro- pylene, or other synthetic blends, Dura-Plex can handle significantly higher working loads.

Samson Dura-Plex also pro- vides four other important fea- tures for barge lines. It has lower stretch than other ropes, which means low snapback.

Firm, round construction holds better on bitts and cleats.

Torque-free and non-kinking the design of fuel-oil burners and associated combustion-chamber characteristics. Adherence to gen- eral guidelines, supplemented by certain analytical procedures and tests, has been the design ap- proach utilized when dealing with an area as technically complex as oil-burner performance and fur- nace design.

The design of burners and their component parts has been a prod- uct of theoretical studies, empir- ical testing and operating results. makes it safer and easier to han- dle. And it's the fastest splicing of any rope.

Dura-Plex is extremely cost effective for tie-up, breast, lock, and mooring lines. Sizes from

XA" to 4" diameter; tensiles from 1,940, to 337,000 lbs.

For complete data, including comparative tensile strengths, write Samson Ocean Systems,

Inc., 99 High St., Boston, MA. 02110. In Canada, contact

Canada Ropes Limited,

Richmond, B.C.

It is generally difficult to predict how a newly designed burner will operate and only testing and ac- tual use of the burner can prove its merits. Since a burner is ba- sically a combination of three ma- jor components — the fuel atom- izer, the diffuser, and the burner throat — the design of each must be given careful consideration.

The configuration of marine- boiler furnaces has changed over the years from a refractory-lined box, used with the earliest coal- fired watertube boilers, to fur- naces which are virtually all water cooled.

Bunker C Fuels

The bunker C fuel used in ma- rine boilers is a nonspecification fuel composed primarily of resid- uum, a substance left from various refinery processes and distillate to obtain a blend reasonably similar in characteristics to No. 6 speci- fication fuel. Because bunker C fuels are made up from the resi- due of refining processes, they are inherently varied in chemical makeup due not only to the geo- graphic sources of the crudes from which they are derived but also to the cracking process used.

There is a paucity of published information on sulfur and trace metals content of bunker C fuels available in bunkering ports. Al- though ships collect fuel samples during bunkering, very few sam- ples are tested unless a serious problem occurs. Consideration of the need for this information in boiler reliability predictions of superheater and cold-end heat- recovery equipment resulted in a bunker C fuel sample collection and analysis program.

It is recommended that ship op- erators and the marine industry monitor fuel quality so that suit- able equipment procurements may be made to accommodate this con- dition.

Summary

The objective of this paper has been to examine several parame- ters dealing with boiler design, materials selection and operating environment which have a sig- nificant effect on overall marine boiler reliability and to present the R&D effort that is currently underway. The ultimate aim of this effort is to present informa- tion which will allow the pur- chaser of steam generating equip- ment to specify certain design and material features in a marine boiler which should enable the boiler operator to obtain a higher degree of boiler reliability, there- by reducing unscheduled outages and decreasing maintenance costs.

The ongoing shipboard and lab- oratory testing described should produce information of the same type and caliber which deals spe- cifically with marine components and operating environment as is available to shoreside operators.

Results of these investigations will be made available periodically during the next two years through the Maritime Administration. SAMSON OCEAN SYSTEMS, INC.

New Dura-Plex Barge Line has the guts to outlast all others. 18 Maritime Reporter/Engineering News

15

15

17

17