Page 28: of Maritime Reporter Magazine (August 15, 1978)

Read this page in Pdf, Flash or Html5 edition of August 15, 1978 Maritime Reporter Magazine

Arctic Transportation Ltd. Commissions

Research Vessel To Work For Imperial Oil

Jakobson Shipyard Delivers Innovative

Oil Skimmer Catamaran To Lagoven, C.A.

Built by Bel-Aire Shipyards Ltd., the 115-foot Arctic Surveyor will tow a mile and one-half-long cable in search for potential oil or gas formations in the earth.

Arctic Transportation Ltd. of

Calgary, Alberta, Canada, com- missioned its new seismic re- search vessel Arctic Surveyor on

July 10 in Vancouver, British Co- lumbia. Sponsor of the vessel was

Mrs. Lloyd R. Hatlelid, whose hus- band is senior geophysicist with the Exploration Department of

Imperial Oil Ltd., Calgary.

Built by Bel-Aire Shipyards

Ltd. to the design of Cleaver &

Walkingshaw Ltd., the 115-foot by 42-foot by 12-foot vessel is powered by two Caterpillar diesel engines which develop a total of 1,700 bhp at 1,225 rpm, producing a free-running speed of 14 knots.

The vessel has a heliport, as well as specialized equipment lo- cated in an instrument building on deck. During the exploration process, a mile and one-half-long cable is towed behind the vessel and sonic signals are detonated in the water while the acoustic de- vices are suspended from deck outrigger cranes. The sonic deflec- tions or vibrations, sent through the earth formations, are picked up by the trailing cable, moni- tored and relayed to special seis- mic recording instruments. Data from this environmentally safe procedure is then processed and used in determining potential oil or gas formations in the earth.

Following commissioning cere- monies, the vessel departed on her maiden voyage for the Beaufort

Sea in the western Canadian Arc- tic, via the ocean route around

Point Barrow, Alaska. The vessel will work on long-term charter to

Imperial Oil Ltd. in the Beaufort

Sea and Mackenzie Delta areas.

Arctic Transportation Ltd. is a

Canadian marine transportation joint venture established by Sea- span International Ltd. of Van- couver, Federal Commerce & Nav- igation Ltd. of Montreal, and

Crowley Maritime Corporation of

Seattle, Wash. acetferky

UHEl

SERVING-

A CITIES

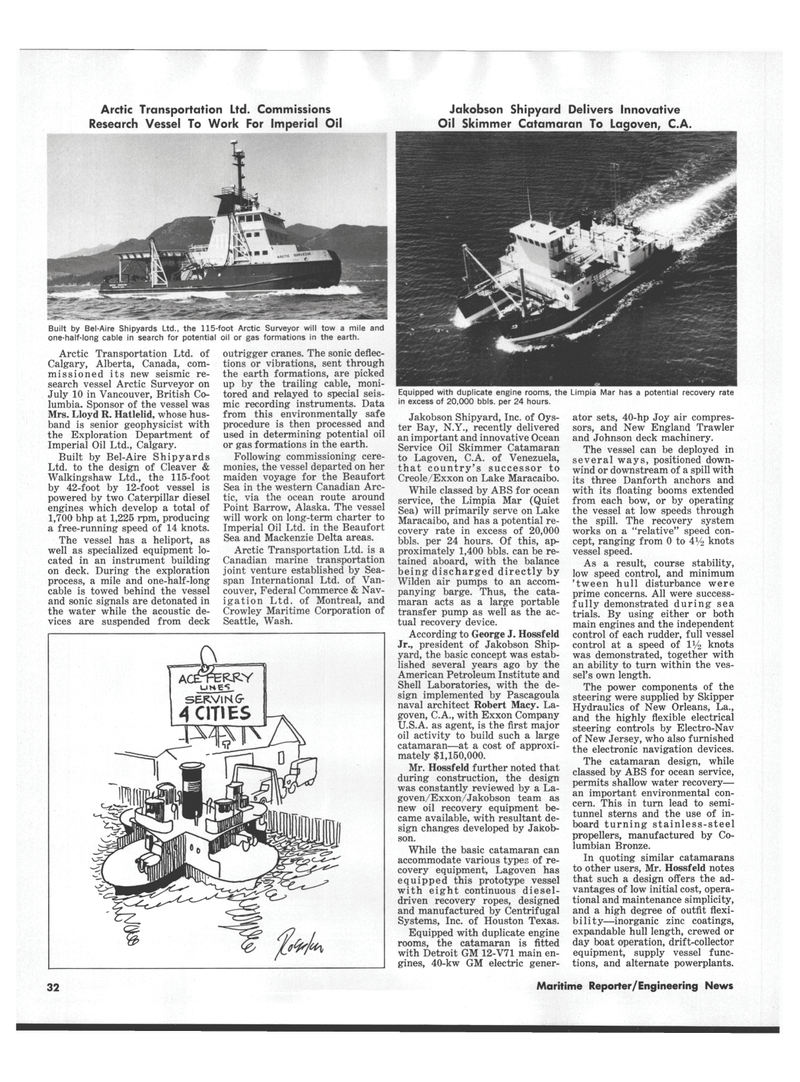

Equipped with duplicate engine rooms, the Limpia Mar has a potential recovery rate in excess of 20,000 bbls. per 24 hours.

Jakobson Shipyard, Inc. of Oys- ter Bay, N.Y., recently delivered an important and innovative Ocean

Service Oil Skimmer Catamaran to Lagoven, C.A. of Venezuela, that country's successor to

Creole/Exxon on Lake Maracaibo.

While classed by ABS for ocean service, the Limpia Mar (Quiet

Sea) will primarily serve on Lake

Maracaibo, and has a potential re- covery rate in excess of 20,000 bbls. per 24 hours. Of this, ap- proximately 1,400 bbls. can be re- tained aboard, with the balance being discharged directly by

Wilden air pumps to an accom- panying barge. Thus, the cata- maran acts as a large portable transfer pump as well as the ac- tual recovery device.

According to George J. Hossfeld

Jr., president of Jakobson Ship- yard, the basic concept was estab- lished several years ago by the

American Petroleum Institute and

Shell Laboratories, with the de- sign implemented by Pascagoula naval architect Robert Macy. La- goven, C.A., with Exxon Company

U.S.A. as agent, is the first major oil activity to build such a large catamaran—at a cost of approxi- mately $1,150,000.

Mr. Hossfeld further noted that during construction, the design was constantly reviewed by a La- goven/Exxon/Jakobson team as new oil recovery equipment be- came available, with resultant de- sign changes developed by Jakob- son.

While the basic catamaran can accommodate various types of re- covery equipment, Lagoven has equipped this prototype vessel with eight continuous diesel- driven recovery ropes, designed and manufactured by Centrifugal

Systems, Inc. of Houston Texas.

Equipped with duplicate engine rooms, the catamaran is fitted with Detroit GM 12-V71 main en- gines, 40-kw GM electric gener- ator sets, 40-hp Joy air compres- sors, and New England Trawler and Johnson deck machinery.

The vessel can be deployed in several ways, positioned down- wind or downstream of a spill with its three Danforth anchors and with its floating booms extended from each bow, or by operating the vessel at low speeds through the spill. The recovery system works on a "relative" speed con- cept, ranging from 0 to 4V2 knots vessel speed.

As a result, course stability, low speed control, and minimum 'tween hull disturbance were prime concerns. All were success- fully demonstrated during sea trials. By using either or both main engines and the independent control of each rudder, full vessel control at a speed of 1% knots was demonstrated, together with an ability to turn within the ves- sel's own length.

The power components of the steering were supplied by Skipper

Hydraulics of New Orleans, La., and the highly flexible electrical steering controls by Electro-Nav of New Jersey, who also furnished the electronic navigation devices.

The catamaran design, while classed by ABS for ocean service, permits shallow water recovery— an important environmental con- cern. This in turn lead to semi- tunnel sterns and the use of in- board turning stainless-steel propellers, manufactured by Co- lumbian Bronze.

In quoting similar catamarans to other users, Mr. Hossfeld notes that such a design offers the ad- vantages of low initial cost, opera- tional and maintenance simplicity, and a high degree of outfit flexi- bility—inorganic zinc coatings, expandable hull length, crewed or day boat operation, drift-collector equipment, supply vessel func- tions, and alternate powerplants. 32 Maritime Reporter/Engineering News

27

27

29

29