Page 14: of Maritime Reporter Magazine (July 1981)

Read this page in Pdf, Flash or Html5 edition of July 1981 Maritime Reporter Magazine

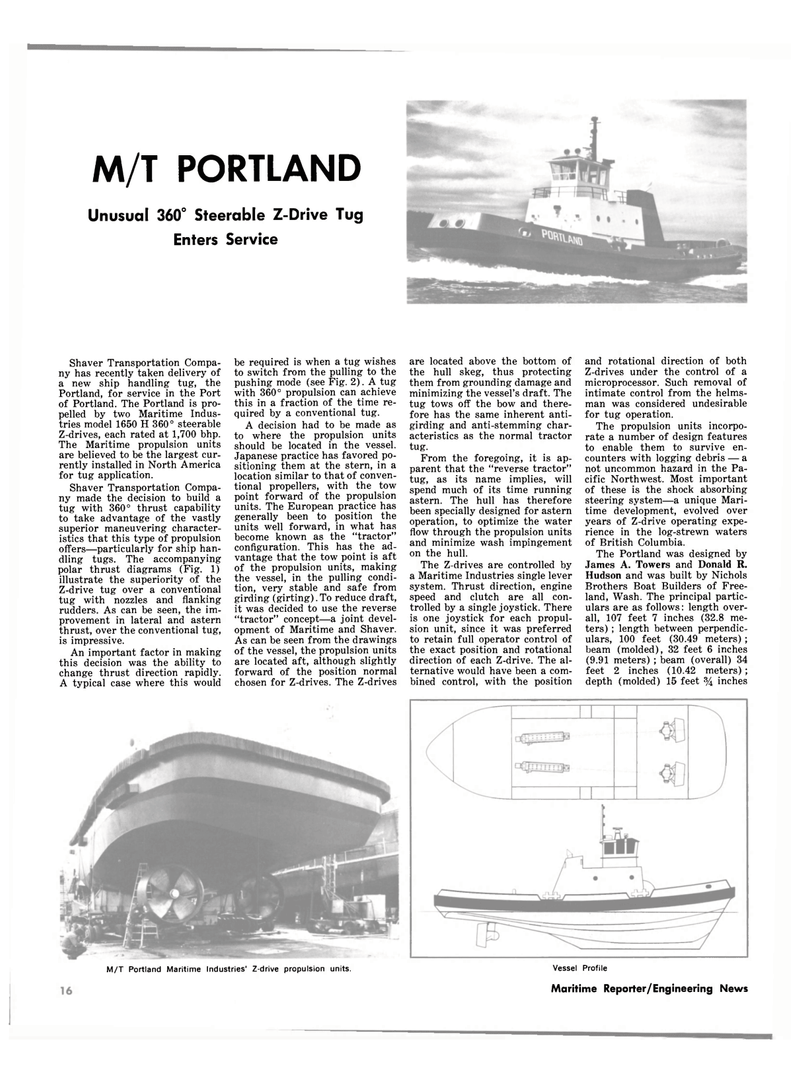

M/T PORTLAND

Unusual 360° Steerable Z-Drive Tug

Enters Service

Shaver Transportation Compa- ny has recently taken delivery of a new ship handling tug, the

Portland, for service in the Port of Portland. The Portland is pro- pelled by two Maritime Indus- tries model 1650 H 360° steerable

Z-drives, each rated at 1,700 bhp.

The Maritime propulsion units are believed to be the largest cur- rently installed in North America for tug application.

Shaver Transportation Compa- ny made the decision to build a tug with 360° thrust capability to take advantage of the vastly superior maneuvering character- istics that this type of propulsion offers—particularly for ship han- dling tugs. The accompanying polar thrust diagrams (Fig. 1) illustrate the superiority of the

Z-drive tug over a conventional tug with nozzles and flanking rudders. As can be seen, the im- provement in lateral and astern thrust, over the conventional tug, is impressive.

An important factor in making this decision was the ability to change thrust direction rapidly.

A typical case where this would be required is when a tug wishes to switch from the pulling to the pushing mode (see Fig. 2). A tug with 360° propulsion can achieve this in a fraction of the time re- quired by a conventional tug.

A decision had to be made as to where the propulsion units should be located in the vessel.

Japanese practice has favored po- sitioning them at the stern, in a location similar to that of conven- tional propellers, with the tow point forward of the propulsion units. The European practice has generally been to position the units well forward, in what has become known as the "tractor" configuration. This has the ad- vantage that the tow point is aft of the propulsion units, making the vessel, in the pulling condi- tion, very stable and safe from girding (girting).To reduce draft, it was decided to use the reverse "tractor" concept—a joint devel- opment of Maritime and Shaver.

As can be seen from the drawings of the vessel, the propulsion units are located aft, although slightly forward of the position normal chosen for Z-drives. The Z-drives

M/T Portland Maritime Industries' Z-drive propulsion units. are located above the bottom of the hull skeg, thus protecting them from grounding damage and minimizing the vessel's draft. The tug tows off the bow and there- fore has the same inherent anti- girding and anti-stemming char- acteristics as the normal tractor tug.

From the foregoing, it is ap- parent that the "reverse tractor" tug, as its name implies, will spend much of its time running astern. The hull has therefore been specially designed for astern operation, to optimize the water flow through the propulsion units and minimize wash impingement on the hull.

The Z-drives are controlled by a Maritime Industries single lever system. Thrust direction, engine speed and clutch are all con- trolled by a single joystick. There is one joystick for each propul- sion unit, since it was preferred to retain full operator control of the exact position and rotational direction of each Z-drive. The al- ternative would have been a com- bined control, with the position and rotational direction of both

Z-drives under the control of a microprocessor. Such removal of intimate control from the helms- man was considered undesirable for tug operation.

The propulsion units incorpo- rate a number of design features to enable them to survive en- counters with logging debris — a not uncommon hazard in the Pa- cific Northwest. Most important of these is the shock absorbing steering system—a unique Mari- time development, evolved over years of Z-drive operating expe- rience in the log-strewn waters of British Columbia.

The Portland was designed by

James A. Towers and Donald R.

Hudson and was built by Nichols

Brothers Boat Builders of Free- land, Wash. The principal partic- ulars are as follows: length over- all, 107 feet 7 inches (32.8 me- ters) ; length between perpendic- ulars, 100 feet (30.49 meters) ; beam (molded), 32 feet 6 inches (9.91 meters) ; beam (overall) 34 feet 2 inches (10.42 meters) ; depth (molded) 15 feet % inches

Vessel Profile 16 Maritime Reporter/Engineering News

13

13

15

15