Page 15: of Maritime Reporter Magazine (July 1981)

Read this page in Pdf, Flash or Html5 edition of July 1981 Maritime Reporter Magazine

Figure 1—Tug comparative thrust dia- gram. will be used to transport raw ma- terial for NKK steel works and are scheduled for completion in 1982.

The new design adopts such energy-saving measures as im- proved propulsion efficiency and waste heat recovery. NKK says these measures will reduce fuel consumption by some 40 percent on the ore/coal carrier. The ves- sel will have a propulsion plant that uses the NKK medium-speed

PC engine, together with a 9- meter, controllable-pitch propel- ler.

Another unique feature is the so-called "Shaft-Generator and

Motor (SGM)" system that, af- ter supplying the needs of vari- ous ship sectors, generates sur- plus electricity by use of waste heat from the main engine to the motor directly linked to the main shaft for additional propulsion.

The vessel also will be equipped with measures for improved waste heat utilization, including a boiler water heating system.

The hull design also will con- serve energy in loading and bal- lasting conditions, and will be coated with an antifouling paint below the waterline to reduce viscous resistance as well as ad- herence of marine organisms.

Figure 2 — Changing from pulling to pushing; comparison of maneuvers; con- ventional tug versus reverse tractor;

Z-drive tug.

Pilothouse consoles showing Maritime single lever Z-drive controls. (4.59 meters) ; draft, 13 feet (3.96 meters) ; propeller speed, 300 rpm; and propeller diameter, 86 inches (2.18 meters).

Her main propulsion power is provided by two Fairbanks Morse 38D81/8 diesel engines. Line han- dling is by means of twin Markey capstans.

New NKK Ship Design

Will Reduce Fuel Use

By Some 40 Percent

NKK (Nippon Kokan) has de- veloped a new basic ship design promoting greater energy con- servation, which will be applied to three vessels (two ore/coal carriers and a bulk carrier) being built for Showa Shipping Com- pany and Nippon Yusen. Shin- ichi Hirayama, president of NKK

America Inc., said these vessels

July 1, 1981

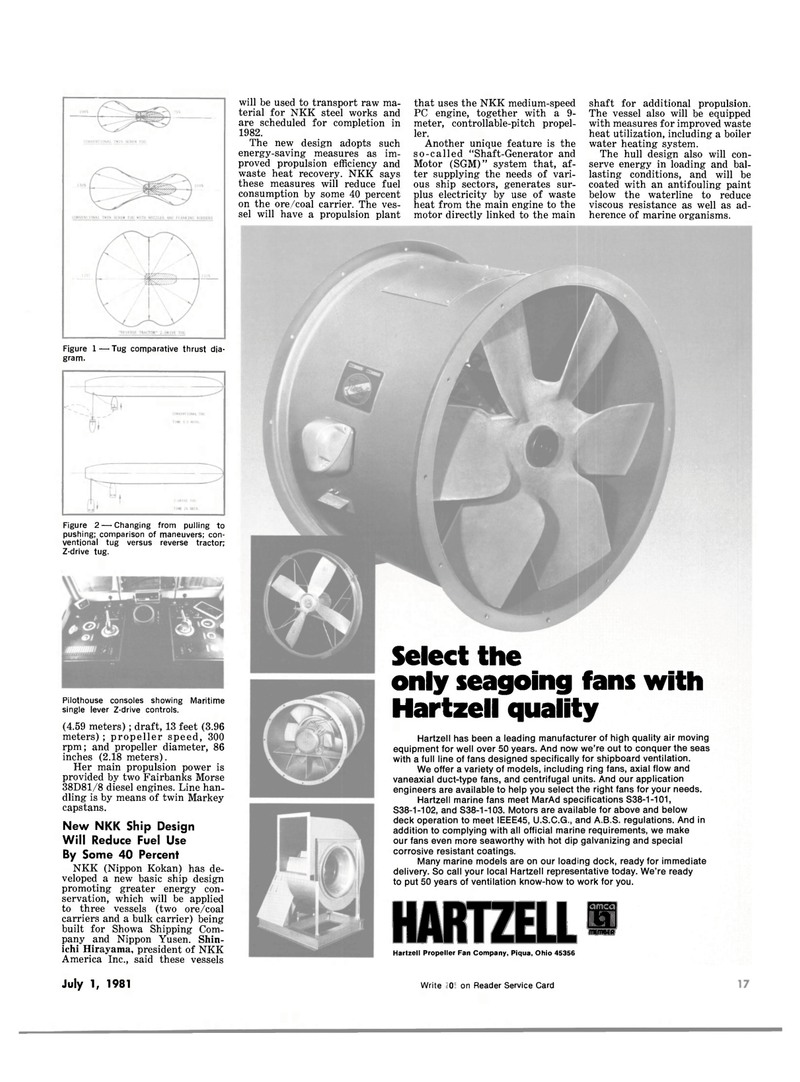

HARTZELL •

Hartzell has been a leading manufacturer of high quality air moving equipment for well over 50 years. And now we're out to conquer the seas with a full line of fans designed specifically for shipboard ventilation.

We offer a variety of models, including ring fans, axial flow and vaneaxial duct-type fans, and centrifugal units. And our application engineers are available to help you select the right fans for your needs.

Hartzell marine fans meet MarAd specifications S38-1-101,

S38-1-102, and S38-1-103. Motors are available for above and below deck operation to meet IEEE45, U.S.C.G., and A.B.S. regulations. And in addition to complying with all official marine requirements, we make our fans even more seaworthy with hot dip galvanizing and special corrosive resistant coatings.

Many marine models are on our loading dock, ready for immediate delivery. So call your local Hartzell representative today. We're ready to put 50 years of ventilation know-how to work for you.

Hartzell Propeller Fan Company, Piqua, Ohio 45356

Write 503 on Reader Service Card 17

Select the only seagoing fans with

Hartzell quality

14

14

16

16