Page 19: of Maritime Reporter Magazine (August 15, 1981)

Read this page in Pdf, Flash or Html5 edition of August 15, 1981 Maritime Reporter Magazine

Paper On Adaptive

Steering Module

Available From Sperry

The Sperry Division of Sperry

Corporation, Great Neck, N.Y., is offering free literature on its new

Adaptive Steering Module (ASM), designed to achieve fuel savings on large commercial ships.

The literature is a reprint of a Sperry paper given to the Soci- ety of Naval Architects and Ma- rine Engineers meeting in Mon- treal, Canada. The paper dis- cusses the development, opera- tion, testing and documented ben- efits of the Sperry ASM.

The ASM is an electronics pack- age which automatically reduces rudder motion under varying speeds, sea states and load condi- tions, thereby reducing rudder drag and increasing fuel effici- ency. The ASM is used in con- junction with Sperry's Universal

Gyropilot, and resulted in fuel savings of up to 2.98 percent, ac- cording to the paper.

For a copy of the Sperry pa- per and more information on the

Adaptive Steering Module,

Write 21 on Reader Service Card $33-Million Ore Handling

Facility Dedicated

At Port Of Toledo

The TORCO Dock, the Port of

Toledo's (Ohio) new $33-million iron ore transfer and ground stor- age facility, was officially dedi- cated into service recently as the port's exclusive transshipment center for taconite ore pellets.

The new ore handling facility, constructed on the site of the former Lakefront coal and ore docks on Maumee Bay, was de- signed to specifically handle self- unloading Great Lakes vessels of up to 1,000 feet in length. It is owned by the Toledo Ore Railroad

Company, a Chessie System sub- sidiary, and operated by the Ches- sie System Railroads, a unit of the CSX Corporation.

Over 150 invited guests, repre- senting government, business and labor, were on hand to hear ded- icatory remarks and tour the fa- cility. Highlighting the afternoon dedication ceremony were ad- dresses from top officials repre- senting five organizations that joined in partnership to develop the new ore center.

The speakers included John A.

McWilliam, president of the To- ledo-Lucas County Port Author- ity, who served as master of ceremonies; John J. Dwyer, pres- ident of the Oglebay Norton Com- pany, Cleveland; John T. Collin- son, president and chief executive officer, Chessie System, Cleve- land ; Stuart M. Reed, president and chief operating officer, Con- solidated Rail Corporation (Con- rail), Philadelphia; and C. Wil- liam Verity Jr., board chairman,

Armco, Inc., Middletown, Ohio.

The ore dock was designed with a system capacity to load railcars from dockside or from ground storage at a rate of 4,000 tons per hour and have capacity to pro- vide ground storage for 800,000 tons. Railcars and ships will no longer be dependent on each other in transferring ore at the dock.

Between five and six million tons of taconite will be shipped through the facility annually.

Armco steel mills, located in

Ashland, Ky., Hamilton and Mid- dletown, Ohio, will be the prin- cipal recipients for the pellets to be transshipped through the

TORCO Dock.

One thousand feet long, the

Columbia Star (See MR/EN,

June 15, 1981, issue, page 16), the largest vessel in Oglebay Norton's

Columbia fleet of lake freighters, will be one of the regular callers at the TORCO Dock. Built spe- cifically for the TORCO trade, she is the first "thousand-footer" ever to call in Toledo.

Gavco To Repair Navy

Drydock For $4.3 Million

Gavco Corporation, Norfolk,

Va., is being awarded a $4,365,- 883 fixed price contract for re- pairs to a drydock at the Norfolk

Naval Shipyard, Portsmouth, Va., following competition in which six bids were received. The Naval

Facilities Engineering Command,

Atlantic Division, is the contract- ing activity. (N62470-80-B-0608)

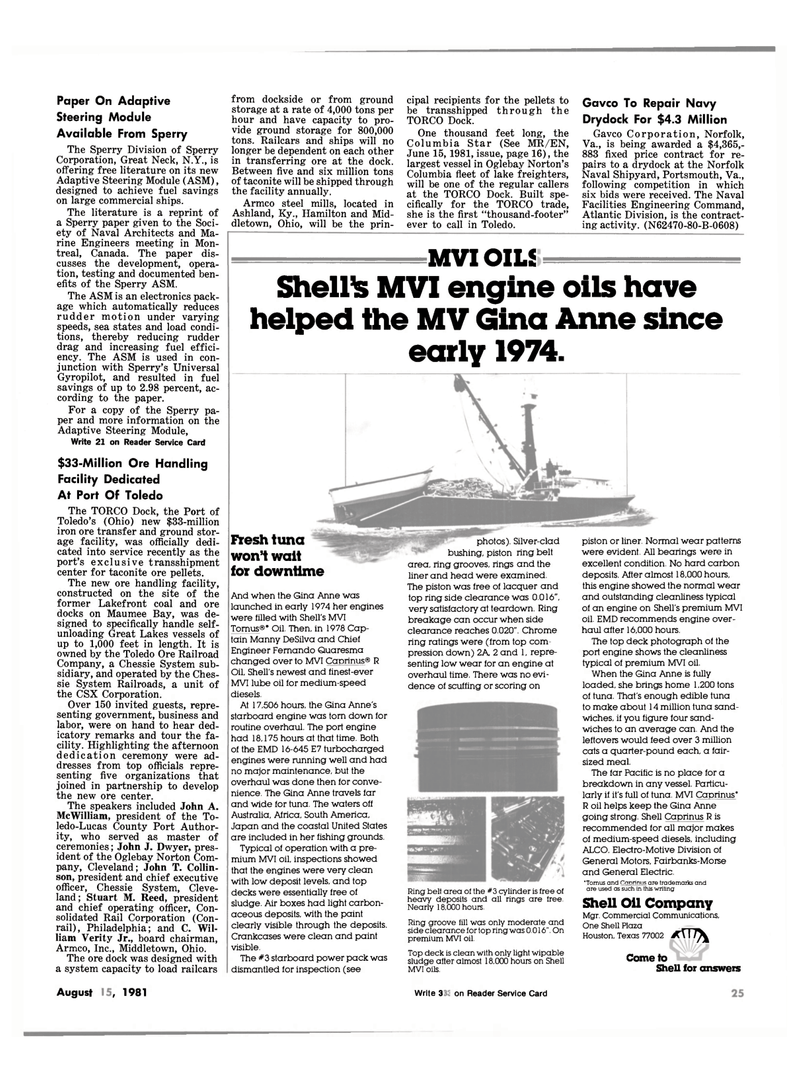

MVI OILS Shells MVI engine oils have helped the M V Gina Anne since early 1974. piston or liner. Normal wear patterns were evident. All bearings were in excellent condition. No hard carbon deposits. Alter almost 18,000 hours, this engine showed the normal wear and outstanding cleanliness typical of an engine on Shell's premium MVI oil. EMD recommends engine over- haul after 16,000 hours.

The top deck photograph ot the port engine shows the cleanliness typical of premium MVI oil.

When the Gina Anne is fully loaded, she brings home 1,200 tons of tuna. That's enough edible tuna to make about 14 million tuna sand- wiches, it you figure lour sand- wiches to an average can. And the leftovers would feed over 3 million cats a quarter-pound each, a fair- sized meal.

The tar Pacific is no place for a breakdown in any vessel. Particu- larly if it's full of tuna. MVI Caprinus*

R oil helps keep the Gina Anne going strong. Shell Caprinus R is recommended tor all major makes of medium-speed diesels, including

ALCO, Electro-Motive Division of

General Motors, Fairbanks-Morse and General Electric. 'Tornus and Caprinus are trademarks and are used as such in this writing

Shell Oil Company

Mgr. Commercial Communications,

One Shell Plaza

Houston, Texas 77002 J^TTT^

Come to Shell for answers

Fresh tuna won't wait for downtime

And when the Gina Anne was launched in early 1974 her engines were tilled with Shell's MVI

Tornus®' Oil. Then, in 1978 Cap- tain Manny DeSilva and Chief

Engineer Fernando Quaresma changed over to MVI Caprinus® R

Oil, Shell's newest and tinest-ever

MVI lube oil for medium-speed diesels.

At 17,506 hours, the Gina Anne's starboard engine was torn down for routine overhaul. The port engine had 18,175 hours at that time. Both of the EMD 16-645 E7 turbocharged engines were running well and had no major maintenance, but the overhaul was done then tor conve- nience. The Gina Anne travels tar and wide tor tuna. The waters oft

Australia, Africa, South America,

Japan and the coastal United States are included in her fishing grounds.

Typical ot operation with a pre- mium MVI oil, inspections showed that the engines were very clean with low deposit levels, and top decks were essentially tree of sludge. Air boxes had light carbon- aceous deposits, with the paint clearly visible through the deposits.

Crankcases were clean and paint visible.

The #3 starboard power pack was dismantled for inspection (see photos). Silver-clad bushing, piston ring belt area, ring grooves, rings and the liner and head were examined.

The piston was free of lacquer and top ring side clearance was 0.016", very satisfactory at teardown. Ring breakage can occur when side clearance reaches 0.020". Chrome ring ratings were (from top com- pression down) 2A 2 and 1, repre- senting low wear tor an engine at overhaul time. There was no evi- dence of scuffing or scoring on

Ring belt area of the #3 cylinder is tree ot heavy deposits and all rings are tree.

Nearly 18,000 hours.

Ring groove fill was only moderate and side clearance tor top ring was 0.016". On premium MVI oil.

Top deck is clean with only light wipable sludge after almost 18,000 hours on Shell

MVI oils.

August 25, 1981 Write 324 on Reader Service Card 13

18

18

20

20