Page 58: of Maritime Reporter Magazine (October 1981)

Read this page in Pdf, Flash or Html5 edition of October 1981 Maritime Reporter Magazine

Moss Point Yard Delivers

Two Supply Boats

Moss Point Marine, Inc., Moss

Point, Miss., delivered two supply vessels, bringing to nine the num- ber of offshore work boats and barges the new shipbuilder has delivered in its first year of op- eration. The Gulf Coast shipyard also announced the signing of a contract for construction of two 250-foot by 72-foot by 16-foot off- shore deck barges.

Included in the recent deliver- ies were a 173-foot supply vessel for Golden Gulf Marine to be op- erated by Bosun-JMJ of New Or- leans, and a 114-foot supply ves- sel for Sea Mar, Inc. of Lafayette.

The 173-foot M./V Golden Girl is the second of 12 vessels contract- ed by Golden Gulf for construc- tion by Moss Point Marine. The 114-foot M/V Cape San Bias is the second such supply boat of a two-boat contract for Sea Mar.

The two 250-foot deck barges, which will be delivered later this year, will be built on Moss Point

Marine's new tilt beam launch system that is capable of han- dling up to 300-foot vessels.

The Golden Girl has a fuel ca- pacity of approximately 57,000 gallons, 1,500 barrels of liquid mud capacity, and 3,600 cubic feet of dry mud. Her deck load capacity is 550 tons and the ves- sel will accommodate a crew of 16 persons. The Cape San Bias has a fuel capacity of 23,700 gal-

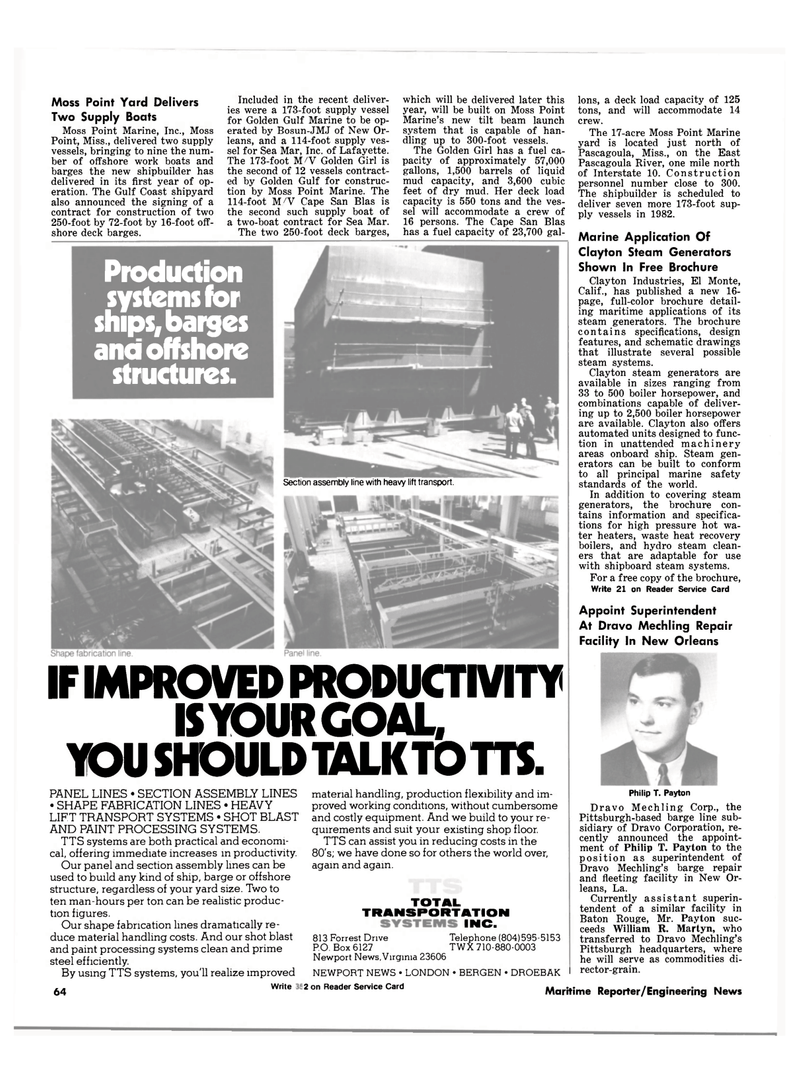

Production systems for ships, barges ana offshore structures.

PANEL LINES • SECTION ASSEMBLY LINES • SHAPE FABRICATION LINES • HEAVY

LIFT TRANSPORT SYSTEMS • SHOT BLAST

AND PAINT PROCESSING SYSTEMS.

TTS systems are both practical and economi- cal, offering immediate increases in productivity.

Our panel and section assembly lines can be used to build any kind of ship, barge or offshore structure, regardless of your yard size. Two to ten man-hours per ton can be realistic produc- tion figures.

Our shape fabrication lines dramatically re- duce material handling costs. And our shot blast and paint processing systems clean and prime steel efficiently.

By using TTS systems, you'll realize improved material handling, production flexibility and im- proved working conditions, without cumbersome and costly equipment. And we build to your re- quirements and suit your existing shop floor.

TTS can assist you in reducing costs in the 80's; we have done so for others the world over, again and again.

TOTAL.

TRANSPORTATION

INC. 813 Forrest Drive

P.O. Box 6127

Telephone (804)595-5153

TWX 710-880-0003

Newport News,Virginia 23606

NEWPORT NEWS • LONDON • BERGEN • DROEBAK I

Ions, a deck load capacity of 125 tons, and will accommodate 14 crew.

The 17-acre Moss Point Marine yard is located just north of

Pascagoula, Miss., on the East

Pascagoula River, one mile north of Interstate 10. Construction personnel number close to 300.

The shipbuilder is scheduled to deliver seven more 173-foot sup- ply vessels in 1982.

Marine Application Of

Clayton Steam Generators

Shown In Free Brochure

Clayton Industries, El Monte,

Calif., has published a new 16- page, full-color brochure detail- ing maritime applications of its steam generators. The brochure contains specifications, design features, and schematic drawings that illustrate several possible steam systems.

Clayton steam generators are available in sizes ranging from 33 to 500 boiler horsepower, and combinations capable of deliver- ing up to 2,500 boiler horsepower are available. Clayton also offers automated units designed to func- tion in unattended machinery areas onboard ship. Steam gen- erators can be built to conform to all principal marine safety standards of the world.

In addition to covering steam generators, the brochure con- tains information and specifica- tions for high pressure hot wa- ter heaters, waste heat recovery boilers, and hydro steam clean- ers that are adaptable for use with shipboard steam systems.

For a free copy of the brochure,

Write 21 on Reader Service Card

Appoint Superintendent

At Dravo Mechling Repair

Facility In New Orleans

Philip T. Payton

Dravo Mechling Corp., the

Pittsburgh-based barge line sub- sidiary of Dravo Corporation, re- cently announced the appoint- ment of Philip T. Payton to the position as superintendent of

Dravo Mechling's barge repair and fleeting facility in New Or- leans, La.

Currently assistant superin- tendent of a similar facility in

Baton Rouge, Mr. Payton suc- ceeds William R. Martyn, who transferred to Dravo Mechling's

Pittsburgh headquarters, where he will serve as commodities di- rector-grain. 64 Write 210 on Reader Service Card Maritime Reporter/Engineering News

Section assembly line with heavy lift transport.

IF IMPROVED PRODUCTIVITY IS YOUR GOAL,

YOU SHOULD 1ALK TO TTS.

57

57

59

59