Page 29: of Maritime Reporter Magazine (August 1983)

Read this page in Pdf, Flash or Html5 edition of August 1983 Maritime Reporter Magazine

Pusnes steam deck machinery.

Looking closer at the windlass on any of these large tankers you will notice up to 1,000-hp disc brakes used to drop the anchors under finger tip control. Visit a semisub- mersible on a drilling station and you will find Pusnes mooring sys- tems for chain, chain-wire combo, or all-wire and moored in depths up to 3,500 feet. Systems for greater depths and hostile envi- ronments are under development today.

Pusnes also manufactures mooring equipment for smaller coastal ships, barges, tugboats, off- shore supply boats, pipe-laying barges, and similar vessels.

Minimum crew and safety are

Pusnes trademarks. The unique roto-bollard for mooring rope han- dling is a typical innovation.

Mooring systems for chain, ca- ble, and rope employ steam, elec- tric or hydraulic drives. The equipment can be local or re- motely controlled and, when nec- essary, the mooring forces con- stantly monitored.

Pusnes is part of "SUBTECH"

Norway, a firm developing com- plete diving systems which employ diving bells, underwater vehicles, bell winch systems, divers gas re- covery systems, external life sup- port systems, and the "Hyper- baric" saturated divers lifeboat.

Concern for offshore personnel re- sulted in the development of "Pudes," the controlled extendable protected gangway for dry evac- uation.

Pusnes has a joint venture com- pany in Japan, Nippon-Pusnes, and both are represented in the

U.S. by EMMI Corporation, of

Flemington, N.J.

FMC

Write 31 on Reader Service Card

A 22-page full-color guide de- scribing Link-Belt's crane and ex- cavator line is being offered by

FMC of Bannockburn, 111.

The guide discusses FMC's crane operations, engineering and re- search programs, and the manu- facturing and testing programs for structures and components. Within each of eight categories of Link-

Belt cranes, such as pedestal mounted hydraulic offshore cranes, is a model number and specifica- tions. The specifications include capacity stated in tons and metric tons; capacity at 50-foot radius; maximum crane boom; main drum line pull/line speed for three speeds; and overall length, width, and working weight.

FMC has added a 33-ton (29.93 mt) capacity API-65 to its Sea- hawk series of Link-Belt® hy- draulic offshore cranes. The light- weight 25,000-pound API-65 is specially designed to perform all the material, equipment, and per- sonnel lifting required on offshore oil production platforms and drill- ing rigs, and meets API-2C (1982) specifications.

The API-65 features pin-con- nected components that permit fast modular erection and easy main- tenance. The heaviest component weighs just 7,200 pounds. The compact design features a 7-foot 7-inch tailswing with onboard en- gine and cab, and an overall height of 14 feet 7 inches reducible to 8 feet.

A maximum API rating of 34,200 pounds is achieved with a 50-foot boom at 30-degree radius, best in its class. Superior load handling speed is provided by a matched en- gine, 3-section pump and winch combination that develops 300-450- fpm maximum line speed with 12,600-pounds maximum line pull on main or auxiliary drums. A horsepower limiter prevents en- gine stalling due to excessive loads.

Especially designed for easy maintenance and serviceability, the API-65 hydraulic crane fea- tures a minus 20-degree boom an- gle permitting access to head ma- chinery; full access to both sides of the engine; hydraulic filters with visual indicator; pumps all grouped behind the cab; eye-level winch lo- cation; replaceable bushings in frame and boom foot; fold down bail; replaceable fuel and oil tanks; and cadmium plated bolts and stainless steel pins. A 3/16-inch plate operator cab permits re- peated blasting and repainting.

The API-65 is mounted on a cy- (continued on page 32)

ShallovvLiAfeterLBQiJt^

Ultra Shallow Draft Vessel 14,209 GT module carrier "SNIMOS ACE mw&Wmmw

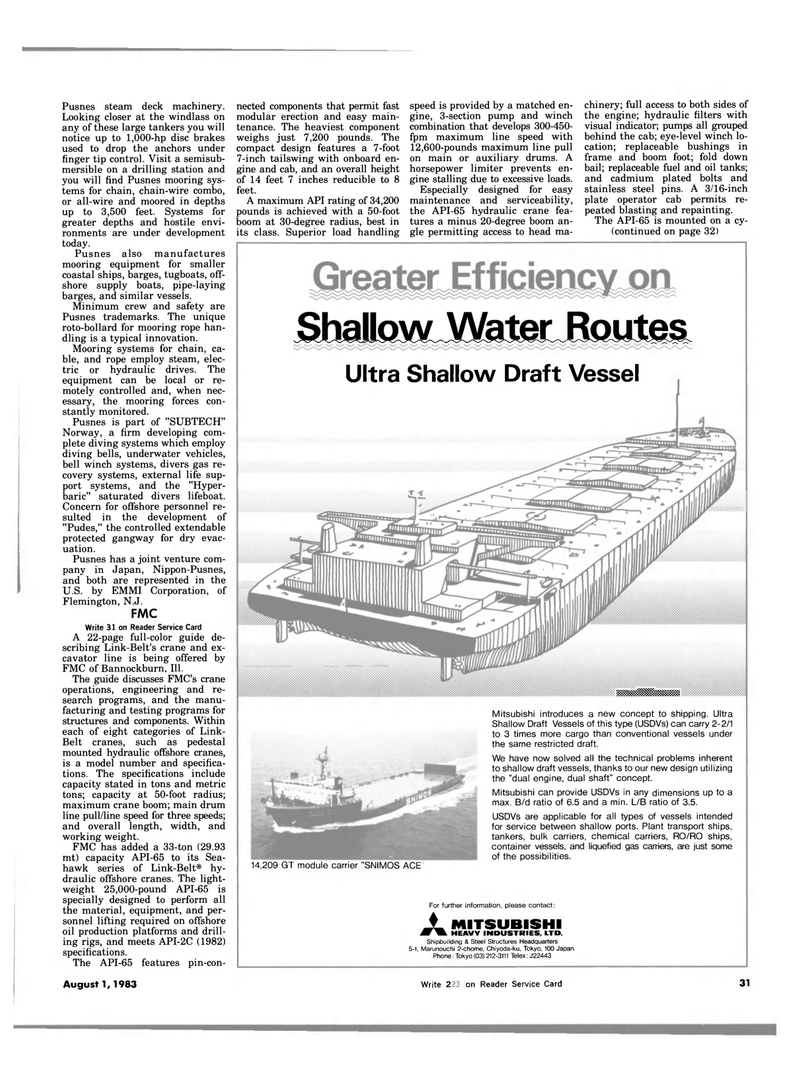

Mitsubishi introduces a new concept to shipping. Ultra

Shallow Draft Vessels of this type (USDVs) can carry 2-2/1 to 3 times more cargo than conventional vessels under the same restricted draft.

We have now solved all the technical problems inherent to shallow draft vessels, thanks to our new design utilizing the "dual engine, dual shaft" concept.

Mitsubishi can provide USDVs in any dimensions up to a max. B/d ratio of 6.5 and a min. L/B ratio of 3.5.

USDVs are applicable for all types of vessels intended for service between shallow ports. Plant transport ships, tankers, bulk carriers, chemical carriers, RO/RO ships, container vessels, and liquefied gas carriers, are just some of the possibilities.

For further information, please contact: A

MITSUBISHI

HEAVY INDUSTRIES. LTD.

Shipbuilding & Steel Structures Headquarters 5-1, Marunouchi 2-chome, Chiyoda-ku, Tokyo, 100 Japan.

Phone: Tokyo (03) 212-3111 Telex: J22443

August 1, 1983 Write 206 on Reader Service Card 31

28

28

30

30