Page 28: of Maritime Reporter Magazine (August 1983)

Read this page in Pdf, Flash or Html5 edition of August 1983 Maritime Reporter Magazine

Deck Machinery

Crosby Group (continued from page 26) of the Crosby Group in Tulsa,

Okla., now has new Roll Forged

Sheaves available in the most complete range of sizes from 12 through 72 inches. The sheaves are an ideal choice for original equipment in self-unloading sys- tems and as replacements.

McKissick sheaves are forged from controlled quality 1035 car- bon steel which provides excellent welding and flame hardening characteristics. All incoming steel is tested by chemical and spectro- graphic methods to insure consis- tently high quality.

Steel sheaves have excellent flexibility when choosing bearings and also provide better cold weather properties than nylon sheaves.

Crosby links and rings are man- ufactured in a complete line of sizes and types for almost any ap- plication, with working load limits from 1,600 to 232,500 pounds.

Lebus products include lever and ratchet type load binders, grab hooks and tail chains, snatch blocks, and hook latch kits. Mc-

Kissick specializes in custom de- signed blocks to any specification, oil field blocks, crane and hook blocks, overhaul balls, swivel

Save 10% to 30% on fuel costs.

Introducing the Avicon Monitor 205 fuel management system. _ 6.75

E

What others promise,

Avicon delivers.

The Avicon Monitor 205 computer-based :uel management system has proved it sharply reduces vessel operating costs.

Assures maximum engine performance and minimum fuel consumption. Gives early warning of hull fouling, engine and propeller troubles.

All the data needed for efficient fuel management. At the push of a button.

The Avicon Monitor 205 provides needed data quickly, easily, positively.

Includes vessel speed, RPM, fuel flow, efficiency, fuel used, propeller slip, time and distance. Function input data includes fuel viscosity and density, fuel flow and RPM alarms, time periods for averaging, speed and fuel flow, and pitch of fixed propellers.

Continuous monitoring.

Once the Avicon Monitor 205 has quickly established fuel savings procedures, it helps ships' personnel carry them out. Effectively saves fuel at running speeds, low speeds, and idling.

Makes en route fuel savings decisions routine. Increases crews' knowledge of fuel saving procedures. Provides positive proof of effectiveness. Provides positive

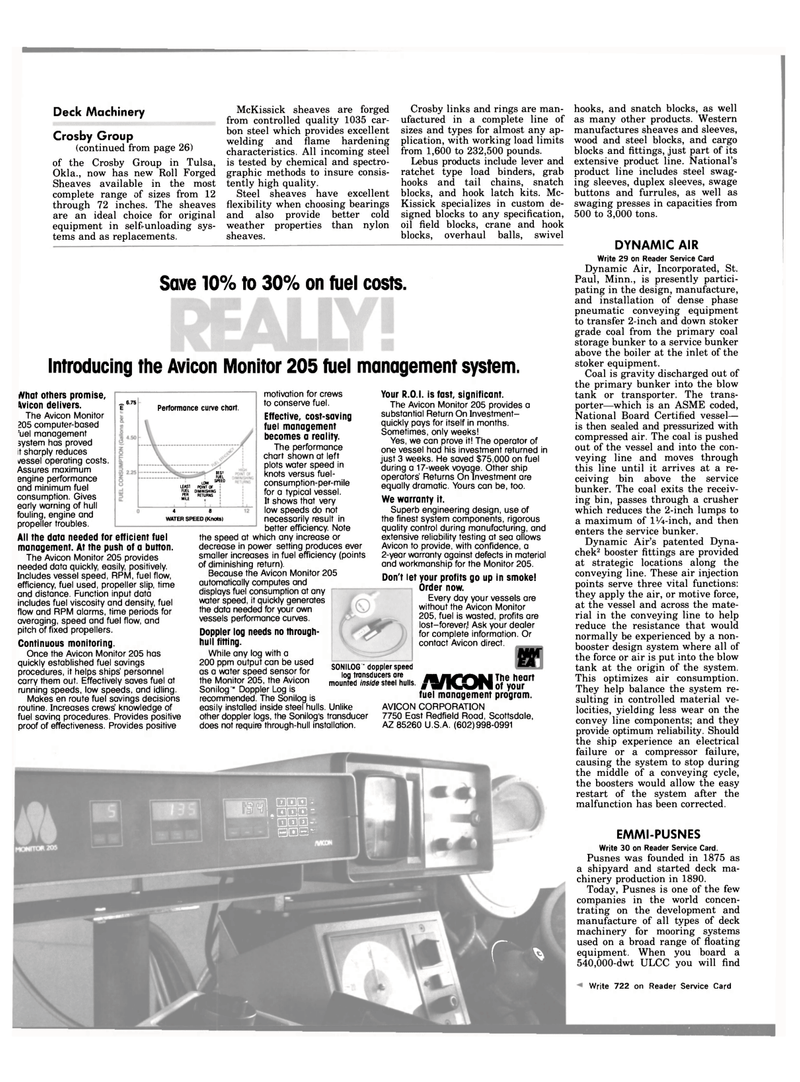

Performance curve chart. motivation for crews to conserve fuel.

BE ST

FUEL

LOW SPH0 LEAST POINT Of

FUEL DIMINISHING

Ftf RETURNS

MILE , 4 8

WATER SPEED (Knots)

Effective, cost-saving fuel management becomes a reality.

The performance chart shown at left plots water speed in knots versus fuel- consumption-per-mile for a typical vessel.

It shows that very low speeds do not necessarily result in better efficiency. Note the speed at which any increase or decrease in power setting produces ever smaller increases in fuel efficiency (points of diminishing return).

Because the Avicon Monitor 205 automatically computes and displays fuel consumption at any water speed, it quickly generates the data needed for your own vessels performance curves.

Doppler log needs no through- hull fitting.

While any log with a 200 ppm output can be used as a water speed sensor for the Monitor 205, the Avicon

Sonilog"" Doppler Log is recommended. The Sonilog is easily installed inside steel hulls. Unlike other doppler logs, the Sonilog's transducer does not require through-hull installation.

Your R.O.I, is fast, significant.

The Avicon Monitor 205 provides a substantial Return On Investment- quickly pays for itself in months.

Sometimes, only weeks!

Yes, we can prove it! The operator of one vessel had his investment returned in just 3 weeks. He saved $75,000 on fuel during a 17-week voyage. Other ship operators' Returns On Investment are equally dramatic. Yours can be, too.

We warranty it.

Superb engineering design, use of the finest system components, rigorous quality control during manufacturing, and extensive reliability testing at sea allows

Avicon to provide, with confidence, a 2-year warranty against defects in material and workmanship for the Monitor 205.

Don't let your profits go up in smoke!

Order now.

Every day your vessels are without the Avicon Monitor 205, fuel is wasted, profits are lost-forever,! Ask your dealer for complete information. Or contact Avicon direct.

SONILOG ' doppler speed log transducers are mounted inside steel hulls. m

Aifl/YMd The heart

M nf •V.v^l'^ of your fuel management program.

AVICON CORPORATION 7750 East Redfield Road, Scottsdale,

AZ 85260 U.S.A. (602)998-0991

Bt SHE -HLssa- • msa-ehdb* f * hooks, and snatch blocks, as well as many other products. Western manufactures sheaves and sleeves, wood and steel blocks, and cargo blocks and fittings, just part of its extensive product line. National's product line includes steel swag- ing sleeves, duplex sleeves, swage buttons and furrules, as well as swaging presses in capacities from 500 to 3,000 tons.

DYNAMIC AIR

Write 29 on Reader Service Card

Dynamic Air, Incorporated, St.

Paul, Minn., is presently partici- pating in the design, manufacture, and installation of dense phase pneumatic conveying equipment to transfer 2-inch and down stoker grade coal from the primary coal storage bunker to a service bunker above the boiler at the inlet of the stoker equipment.

Coal is gravity discharged out of the primary bunker into the blow tank or transporter. The trans- porter—which is an ASME coded,

National Board Certified vessel— is then sealed and pressurized with compressed air. The coal is pushed out of the vessel and into the con- veying line and moves through this line until it arrives at a re- ceiving bin above the service bunker. The coal exits the receiv- ing bin, passes through a crusher which reduces the 2-inch lumps to a maximum of IVi-inch, and then enters the service bunker.

Dynamic Air's patented Dyna- chek2 booster fittings are provided at strategic locations along the conveying line. These air injection points serve three vital functions: they apply the air, or motive force, at the vessel and across the mate- rial in the conveying line to help reduce the resistance that would normally be experienced by a non- booster design system where all of the force or air is put into the blow tank at the origin of the system.

This optimizes air consumption.

They help balance the system re- sulting in controlled material ve- locities, yielding less wear on the convey line components; and they provide optimum reliability. Should the ship experience an electrical failure or a compressor failure, causing the system to stop during the middle of a conveying cycle, the boosters would allow the easy restart of the system after the malfunction has been corrected.

EMMI-PUSNES

Write 30 on Reader Service Card.

Pusnes was founded in 1875 as a shipyard and started deck ma- chinery production in 1890.

Today, Pusnes is one of the few companies in the world concen- trating on the development and manufacture of all types of deck machinery for mooring systems used on a broad range of floating equipment. When you board a 540,000-dwt ULCC you will find

Write 722 on Reader Service Card

27

27

29

29