Page 3: of Maritime Reporter Magazine (January 15, 1984)

Read this page in Pdf, Flash or Html5 edition of January 15, 1984 Maritime Reporter Magazine

Brown & Root Inc. Forms

Joint Venture In Holland

With Two Dutch Companies

Brown & Root Inc. of Houston has formed a joint venture in Hol- land with its Netherland subsidi- ary and two Dutch shipyards to pursue work in the Dutch sector of the North Sea. Brown & Root, a

Halliburton Company, is one of the world's largest and most diver- sified engineering and construc- tion companies.

The new joint venture, Building

Combination Nederlands B.V. (BCN) is composed of Brown &

Root Nederland B.V., Nederlandse

Scheepsbouw Maatschappij B.V. (NSM) and Constructiegroep Noord

Nederland B.V. (CNN). The com- pany will design, engineer, fabri- cate, install and hook up platforms in the Dutch sector of the North

Sea.

BCN has an authorized share capital of 1 million Dutch guild- ers. Shareholding is divided equally among the three companies of the joint venture. BCN will operate from NSM offices at 73 Klaproz- enweg, Amsterdam. NSM is a ma- jor Dutch shipbuilder and fabrica- tor, and CNN is an amalgamation of two Dutch fabricators and ship- builders in Northern Holland.

Managing directors of the new company are V.F. Hill of Brown &

Root, H. Ketting of N.S.M. and

E.B. Schmied of CNN.

Newport News Awarded $3.4-Million Navy Contract

For Planning Yard Services

Newport News Shipouilding and

Drydock Company, Newport News,

Va., is being awarded a $3,418,359 cost-plus-fixed-fee contract for planning yard services for USS

Enterprise (CVN-65) and USS Long

Beach (CGN-9) in FY-84. The Na- val Sea Systems Command, Wash- ington, D.C., is the contracting ac- tivity (N00024-80-C-4038).

Bethlehem Steel Signs

Licensing Agreement For

Tension Moored Platforms

Bethlehem Steel Corpration re- cently signed a long-term licens- ing agreement for highly ad- vanced offshore oil production technology—tension moored plat- forms (TMP) with Fluor Engi- neers, Inc. The announcement was issued jointly by David H. Klinges, vice president of Bethlehem's ma- rine construction group, and F.

Sweeney Tuck, president of Ocean

Services Division of Fluor

Engineers.

The agreement combines Fluor's design technology and extensive marketing experience in the off- shore industry with Bethlehem's engineering and construction serv- ices which have been serving the offshore and marine industries since 1905.

Mr. Klinges said for production platform applications, "the TMP design offers a real cost advantage where its only competitors are the various and very costly rigid or guyed tower designs." These, he noted, become prohibitively expen- sive for depths over 1,200 feet.

The TMP design is a platform resembling a semi-submersible that is rigidly attached to several piled anchors through multiple tension legs of wire rope or tubing. The buoyancy of the platform at all times exceeds its weight, keeping the legs in tension. Mr. Tuck noted that his company holds sev- eral patents in tension moored platform technology and has been a leader in this field since the late 1960s.

The agreement gives Bethlehem

Steel the exclusive right to build

TMPs with Fluor technology on the East and Gulf Coasts of North and Central America and the

Caribbean.

Although equipment sales to the offshore industry are currently stagnant, Mr. Klinges said that optimism and prices paid for re- cent leases in the Gulf of Mexico indicate real confidence on the part of the oil companies in a re- newal of offshore activity. "We see this rise in activity," the Bethle- hem executive continued, "occur- ring over the next two or three years, and we intend to utilize this period to place ourselves in a good marketing position, offering a broad line of equipment to the industry."

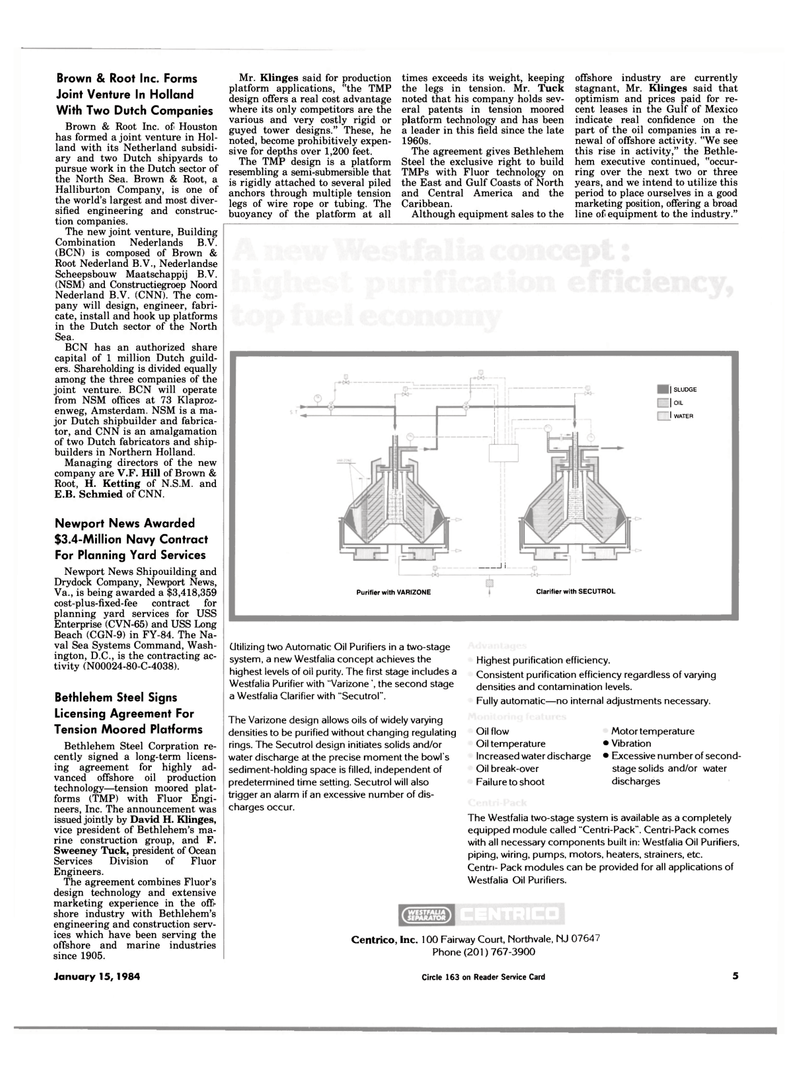

Utilizing two Automatic Oil Purifiers in a two-stage system, a new Westfalia concept achieves the highest levels of oil purity. The first stage includes a

Westfalia Purifier with "Varizone', the second stage a Westfalia Clarifier with "Secutrol".

The Varizone design allows oils of widely varying densities to be purified without changing regulating rings. The Secutrol design initiates solids and/or water discharge at the precise moment the bowl's sediment-holding space is filled, independent of predetermined time setting. Secutrol will also trigger an alarm if an excessive number of dis- charges occur.

Highest purification efficiency.

Consistent purification efficiency regardless of varying densities and contamination levels.

Fully automatic—no internal adjustments necessary.

Oil flow Motor temperature

Oil temperature Vibration

Increased water discharge Excessive number of second-

Oil break-over stage solids and/or water

Failure to shoot discharges

The Westfalia two-stage system is available as a completely equipped module called "Centri-Pack". Centri-Pack comes with all necessary components built in: Westfalia Oil Purifiers, piping, wiring, pumps, motors, heaters, strainers, etc.

Centri- Pack modules can be provided for all applications of

Westfalia Oil Purifiers.

CENTRICO

Centrico, Inc. 100 Fairway Court, Northvale, NJ 07647

Phone (201)767-3900

Purifier with VARIZONE Clarifier with SECUTROL |SLUDGE | OIL

I WATER

I i

January 15, 1984 Circle 163 on Reader Service Card 5

2

2

4

4