Page 37: of Maritime Reporter Magazine (April 1984)

Read this page in Pdf, Flash or Html5 edition of April 1984 Maritime Reporter Magazine

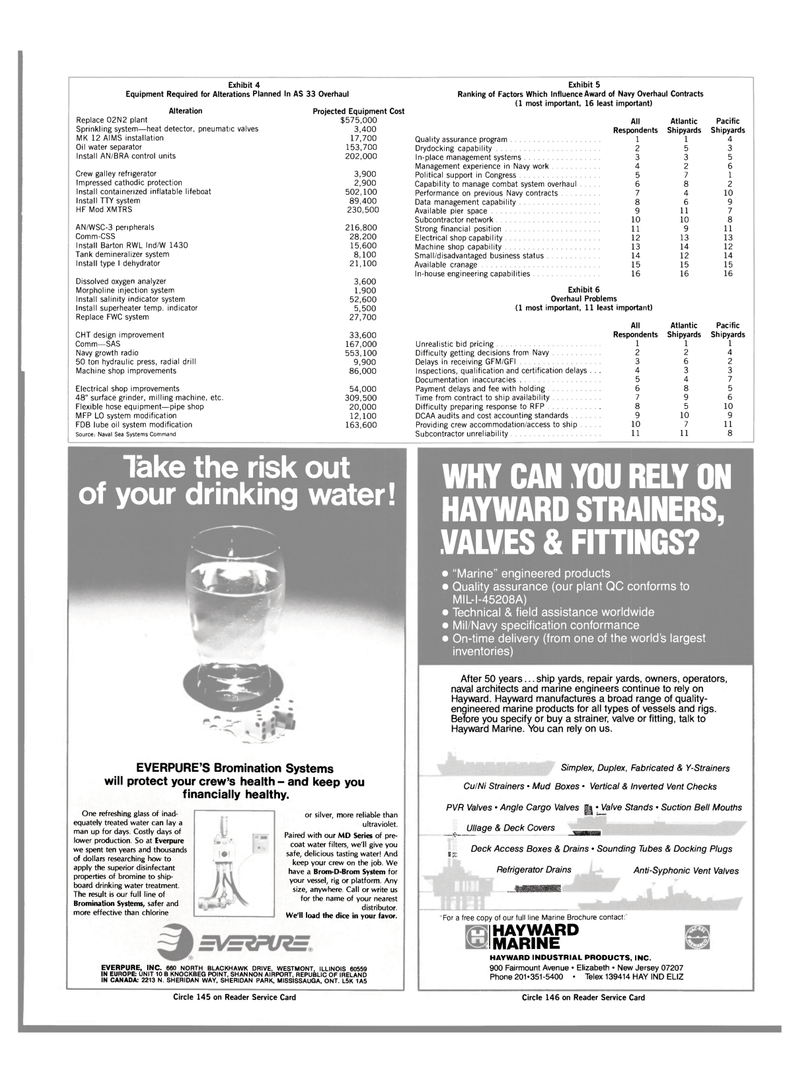

Exhibit 4 Exhibit 5

Equipment Required for Alterations Planned In AS 33 Overhaul Ranking of Factors Which Influence Award of Navy Overhaul Contracts (1 most important, 16 least important)

Alteration Projected Equipment Cost

Replace 02N2 plant $575,000 All Atlantic Pacific

Sprinkling system—heat detector, pneumatic valves 3,400 Respondents Shipyards Shipyards

MK 12 AIMS installation 17,700 Quality assurance program 1 1 4

Oil water separator 153,700 Drydocking capability 2 5 3

Install AN/BRA control units 202,000 In-place management systems 3 3 5

Management experience in Navy work 4 2 6

Crew galley refrigerator 3,900 Political support in Congress 5 7 1

Impressed cathodic protection 2,900 Capability to manage combat system overhaul 6 8 2

Install containerized inflatable lifeboat 502,100 Performance on previous Navy contracts 7 4 10

Install TTY system 89,400 Data management capability 8 6 9

HF Mod XMTRS 230,500 Available pier space

Subcontractor network 9 10 11 10 7 8

AN/WSC-3 peripherals 216,800 Strong financial position 11 9 11

Comm-CSS 28,200 Electrical shop capability 12 13 13

Install Barton RWL Ind/W 1430 15,600 Machine shop capability 13 14 12

Tank demineralizer system 8,100 Small/disadvantaged business status 14 12 14

Install type 1 dehydrator 21,100 Available cranage 15 15 15

In-house engineering capabilities 16 16 16

Dissolved oxygen analyzer 3,600

Morpholine injection system 1,900 Exhibit 6

Install salinity indicator system 52,600 Overhaul Problems

Install superheater temp, indicator 5,500 (1 most important, 11 least important)

Replace FWC system 27,700

All Atlantic Pacific

CHT design improvement 33,600 Respondents Shipyards Shipyards

Comm—SAS 167,000 Unrealistic bid pricing 1 1 1

Navy growth radio 553,100 Difficulty getting decisions from Navy 2 2 4 50 ton hydraulic press, radial drill 9,900 Delays in receiving GFM/GFI 3 6 2

Machine shop improvements 86,000 Inspections, qualification and certification delays . . . 4 3 3

Documentation inaccuracies 5 4 7

Electrical shop improvements 54,000 Payment delays and fee with holding 6 8 5 48" surface grinder, milling machine, etc. 309,500 Time from contract to ship availability 7 9 6

Flexible hose equipment—pipe shop 20,000 Difficulty preparing response to RFP 8 5 10

MFP L0 system modification 12,100 DCAA audits and cost accounting standards 9 10 9

FDB lube oil system modification 163,600 Providing crew accommodation/access to ship 10 7 11

Source: Naval Sea Systems Command Subcontractor unreliability 11 11 8 lake the risk out of your drinking water! WHY CAN YOU RELY ON HAYWARD STRAINERS,

VALVES & FITTINGS? • "Marine" engineered products • Quality assurance (our plant QC conforms to

MIL-I-45208A) • Technical & field assistance worldwide • Mil/Navy specification conformance • On-time delivery (from one of the world's largest inventories)

EVERPURE'S Bromination Systems will protect your crew's health - and keep you financially healthy.

One refreshing glass of inad- equately treated water can lay a man up for days. Costly days of lower production. So at Everpure we spent ten years and thousands of dollars researching how to apply the superior disinfectant properties of bromine to ship- board drinking water treatment.

The result is our full line of

Bromination Systems, safer and more effective than chlorine or silver, more reliable than ultraviolet.

Paired with our MD Series of pre- coat water filters, we'll give you safe, delicious tasting water! And keep your crew on the job. We have a Brom-D-Brom System for your vessel, rig or platform. Any size, anywhere. Call or write us for the name of your nearest distributor.

We'll load the dice in your favor.

EVERPURE, INC. 660 NORTH BLACKHAWK DRIVE, WESTMONT, ILLINOIS 60559 IN EUROPE UNIT 10 B KNOCKBEG POINT, SHANNON AIRPORT, REPUBLIC OF IRELAND

IN CANADA: 2213 N. SHERIDAN WAY, SHERIDAN PARK, MISSISSAUGA, ONT. L5K 1A5

After 50 years... ship yards, repair yards, owners, operators, naval architects and marine engineers continue to rely on

Hayward. Hayward manufactures a broad range of quality- engineered marine products for all types of vessels and rigs.

Before you specify or buy a strainer, valve or fitting, talk to

Hayward Marine. You can rely on us.

Simplex, Duplex, Fabricated & Y-Strainers

Cu/Ni Strainers • Mud Boxes • Vertical & Inverted Vent Checks

PVR Valves • Angle Cargo Valves la • Valve Stands • Suction Bell Mouths ill i

Ullage & Deck Covers ........ ^s — ——— ^JHH

Deck Access Boxes & Drains • Sounding Tubes & Docking Plugs is

Refrigerator Drains -JMHHHHi

Anti-Syphonic Vent Valves "For a free copy of our full line Marine Brochure contact:'

I HAYWARD I MARINE

HAYWARD INDUSTRIAL PRODUCTS, INC. 900 Fairmount Avenue • Elizabeth • New Jersey 07207

Phone 201 »351-5400 • Telex 139414 HAY IND ELIZ

Circle 145 on Reader Service Card Circle 146 on Reader Service Card

36

36

38

38