Page 20: of Maritime Reporter Magazine (October 15, 1984)

Read this page in Pdf, Flash or Html5 edition of October 15, 1984 Maritime Reporter Magazine

Gastech '84 (continued from page 20)

Netherlands

BETA

TNO

Astro-Controls

Autogastechniek Holland

Cirmac

Econosto

Emba-Techniek

Energie Systemen Utrecht

Enraf Nonius

Gas and Liquid Processing

Gautzsch Gimeg Group

Gebruder Adams

Geveke

Holland Shipbuilding

Innogas

Koltec

Marine Industry

Petrogas Gas Systems

Smit Ovens Gas Generators

Vialle Autogas Systems

Norway

Moss Rosenberg

Noroil

Westad

Sweden

ESAB

Switzerland

Societe General de Surveillance

Sulzer

United Kingdom

AFA-Minerva

Bestobell Valves

British Gas Corp./International

Consultancy Service

David Brown Gear Industries

Energy Industries Council

English Electric Valve

Fairplay Ferranti Computer

Systems

Goodwin International

Harland & Wolff Hayward Tyler

Hazardous Cargo Bulletin

Hindle Cockburns

IMI Bailey Birkett

UKAEC—Safety & Reliability

Directorate

Insulation and Perlite Services

IPM Data

Laporte Industries

Liquid Gas Equipment

Lloyd's List

NEI Valtek Engineering

Orbit Valve

PC Engineering Software

Shipham & Co.

SIGTTO

Tekflow International

Thurley International

T.I. Flexible Tubes

Truflo

Woodfield Systems

Worcester Controls

Wormold Fire Systems

United States

Anderson Greenwood

J.C. Carter

CBI/SNCMP (U.S./France)

Detector Electronics

EMIS—Electronic Information

Systems

Flodyne Controls

Gulf Publishing

M.W. Kellogg

Pittsburgh Des Moines

Posi Seal

West Germany

VDMA

VDS

WIM 22

Arca-Regler

Atlas Copco Energas

Otto Bosse

H. Butting

Connex Verladeanlagen

R&M Dammtechnik

EKEP—Erdoel & Kohle Erdgas,

Petrochemie

Gefahrleche Ladung

Hamburger Rohrbogenwerk

Kaefer Isoliertechnik

Kavernen Bau-und Betriebs

KKK-Kuhnle, Kopp & Kausch

LGA Gastechnik

Paul Lindenau

Linde-Werkgruppe Kalte

Linde-Werkgruppe TVT

Liquid Gas International

Marine Service

Jos. L. Meyer

G + H Montage

G. Noell

Pipeline Engineering

Rembe Mess-und Regeltechnik

Rochling Haren

Schichau Unterweser

Gebr. Schmeck

Wiese Verladetechnik

Winter machinery spaces, engine and boiler rooms, etc.

The company's smoke detection systems are also discussed, as well as

Kidde's total marine capability to custom-design the ideal system to meet every marine fire protection need, and the domestic and interna- tional network of qualified experi- enced distributors to install and ser- vice these systems.

For a copy of the Walter Kidde brochure,

Circle 12 on Reader Service Card

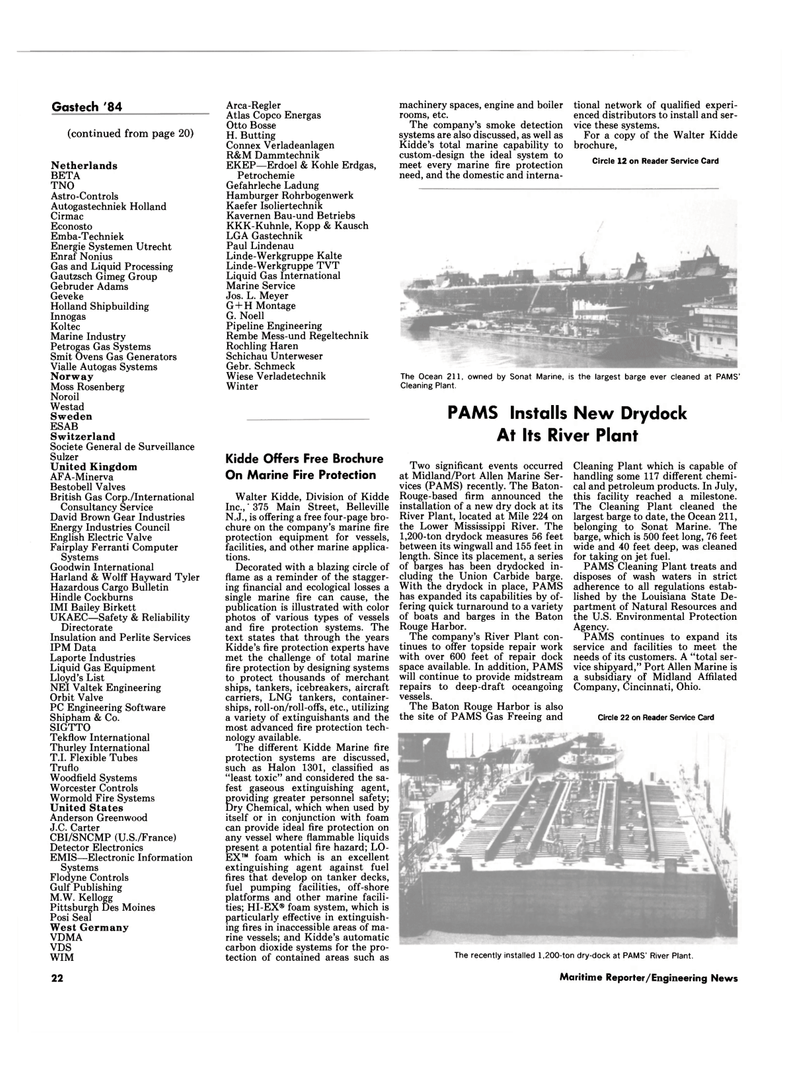

The Ocean 211, owned by Sonat Marine, is the largest barge ever cleaned at PAMS'

Cleaning Plant.

Kidde Offers Free Brochure

On Marine Fire Protection

Walter Kidde, Division of Kidde

Inc.," 375 Main Street, Belleville

N.J., is offering a free four-page bro- chure on the company's marine fire protection equipment for vessels, facilities, and other marine applica- tions.

Decorated with a blazing circle of flame as a reminder of the stagger- ing financial and ecological losses a single marine fire can cause, the publication is illustrated with color photos of various types of vessels and fire protection systems. The text states that through the years

Kidde's fire protection experts have met the challenge of total marine fire protection by designing systems to protect thousands of merchant ships, tankers, icebreakers, aircraft carriers, LNG tankers, container- ships, roll-on/roll-offs, etc., utilizing a variety of extinguishants and the most advanced fire protection tech- nology available.

The different Kidde Marine fire protection systems are discussed, such as Halon 1301, classified as "least toxic" and considered the sa- fest gaseous extinguishing agent, providing greater personnel safety;

Dry Chemical, which when used by itself or in conjunction with foam can provide ideal fire protection on any vessel where flammable liquids present a potential fire hazard; LO-

EX™ foam which is an excellent extinguishing agent against fuel fires that develop on tanker decks, fuel pumping facilities, off-shore platforms and other marine facili- ties; HI-EX® foam system, which is particularly effective in extinguish- ing fires in inaccessible areas of ma- rine vessels; and Kidde's automatic carbon dioxide systems for the pro- tection of contained areas such as

PAMS Installs New Drydock

At Its River Plant

The recently installed 1,200-ton dry-dock at PAMS' River Plant.

Maritime Reporter/Engineering News

Two significant events occurred at Midland/Port Allen Marine Ser- vices (PAMS) recently. The Baton-

Rouge-based firm announced the installation of a new dry dock at its

River Plant, located at Mile 224 on the Lower Mississippi River. The 1,200-ton drydock measures 56 feet between its wingwall and 155 feet in length. Since its placement, a series of barges has been drydocked in- cluding the Union Carbide barge.

With the drydock in place, PAMS has expanded its capabilities by of- fering quick turnaround to a variety of boats and barges in the Baton

Rouge Harbor.

The company's River Plant con- tinues to offer topside repair work with over 600 feet of repair dock space available. In addition, PAMS will continue to provide midstream repairs to deep-draft oceangoing vessels.

The Baton Rouge Harbor is also the site of PAMS Gas Freeing and

Cleaning Plant which is capable of handling some 117 different chemi- cal and petroleum products. In July, this facility reached a milestone.

The Cleaning Plant cleaned the largest barge to date, the Ocean 211, belonging to Sonat Marine. The barge, which is 500 feet long, 76 feet wide and 40 feet deep, was cleaned for taking on jet fuel.

PAMS Cleaning Plant treats and disposes of wash waters in strict adherence to all regulations estab- lished by the Louisiana State De- partment of Natural Resources and the U.S. Environmental Protection

Agency.

PAMS continues to expand its service and facilities to meet the needs of its customers. A "total ser- vice shipyard," Port Allen Marine is a subsidiary of Midland Affilated

Company, Cincinnati, Ohio.

Circle 22 on Reader Service Card

19

19

21

21