Page 123: of Maritime Reporter Magazine (June 1985)

Read this page in Pdf, Flash or Html5 edition of June 1985 Maritime Reporter Magazine

DCC is generally used throughout vessels and offshore units where the ceiling design must comply with and meet the combined requirements of fire protection, sound regulation, aesthetics and simple installation.

DAMPA Continuous Ceiling

Approved By U.S. Navy—

Free Brochure Available

DAMPA Marine has made avail- DAMPA® Continuous Ceiling Sys- able a free 20-page brochure on the tem (DDC) that the company manufactures. The U.S. Navy (NAVSEA)-approved DAMPA

Continuous Ceiling is a lightweight galvanized steel and baked ena- meled with unperforated or perfo- rated surface for increased sound absorption.

The publication, which is gener- ously illustrated with photos, draw- ings and graphs, describes DCC as a steel ceiling system that can be mounted either before, during or after the installation of partitions.

Fire resistant and sound absorbing, the lightweight steel construction combines rigidity and strength. The ceiling units are supplied pre-cut to fit each individual room require- ment, thus reducing labor costs, in- stallation time (approximately six minutes a square foot), and waste of materials; and a wide range of inte- grated components such as lumi- naires, loudspeakers and ventilation units are available. DCC is mar- keted through a worldwide network of subsidiaries and partners, and designers, shipowners and yards have specified and used it in more than 1,000 vessels.

In addition to being U.S. Navy (NAVSEA)-approved for future ap- plication onboard U.S. Navy and

Military Sea Lift Command vessels (new and conversions), DCC fulfills "A" class divisions of A-0, A-15, A- 30, and A-60 standards and "B" class divisions of B-0, B-15, and B- 30, respectively, as defined by IMO

International Conference on Safety of Life at Sea 1974 (SOLAS 1974).

For more information and a free copy of the DAMPA Marine bro- chure,

Circle 312 on Reader Service Card

Erlandson Promoted To

Manager, Engine Division

Of FABCO Equipment Inc.

Joseph G. Fabick, president of

FABCO Equipment Inc., recently announced the promotion of Dave

Erlandson to manager of FABCO

Power Systems, the company's en- gine division.

FABCO Equipment Inc. is the

Caterpillar dealer for the entire state of Wisconsin and Upper Mich- igan.

The "Little" Giant!

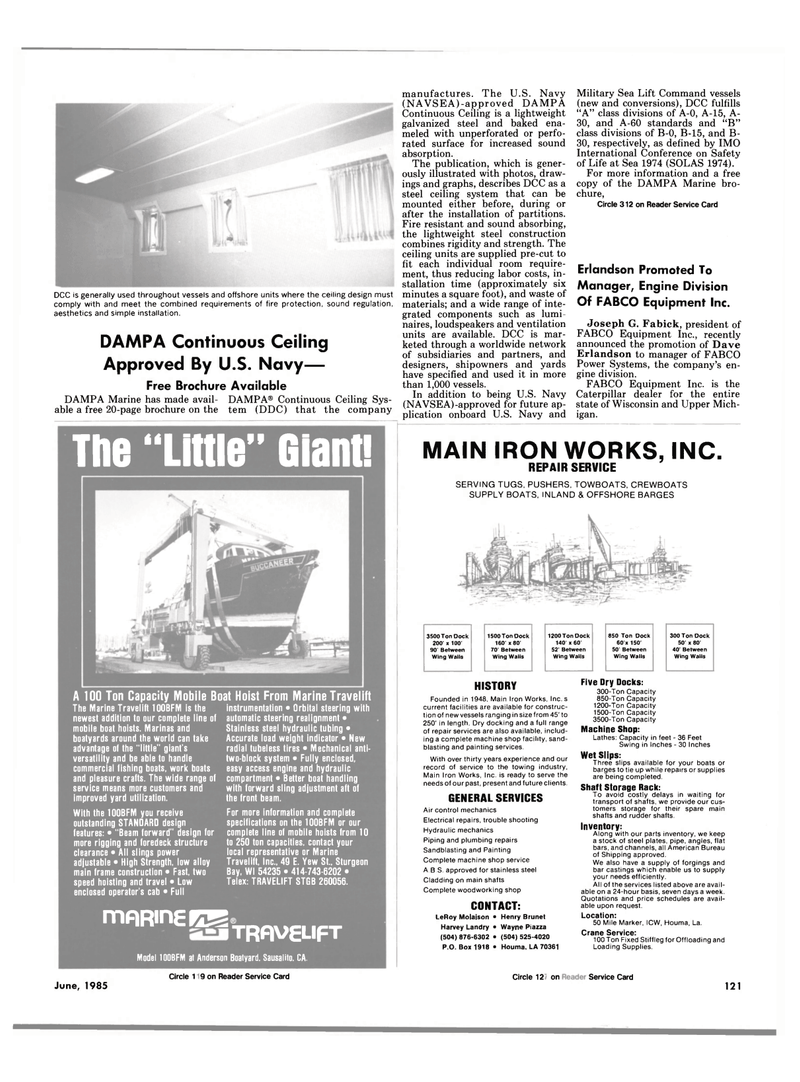

A 100 Ton Capacity Mobile Boat Hoist From Marine Travelift

The Marine Travelift 100BFM is the instrumentation • Orbital steering with newest addition to our complete line of automatic steering realignment • mobile boat hoists. Marinas and Stainless steel hydraulic tubing • boatyards around the world can take Accurate load weight indicator • New advantage of the "little" giant's radial tubeless tires • Mechanical anti- versatility and be able to handle two-block system • Fully enclosed, commercial fishing boats, work boats easy access engine and hydraulic and pleasure crafts. The wide range of compartment • Better boat handling service means more customers and with forward sling adjustment aft of improved yard utilization. the front beam.

With the 100BFM you receive outstanding STANDARD design features: • "Beam forward" design for more rigging and foredeck structure clearance • All slings power adjustable • High Strength, low alloy main frame construction • Fast, two speed hoisting and travel • Low enclosed operator's cab • Full

For more information and complete specifications on the 100BFM or our complete line of mobile hoists from 10 to 250 ton capacities, contact your local representative or Marine

Travelift. Inc., 49 E. Yew St., Sturgeon

Bay. Wl 54235 • 414-743-6202 •

Telex: TRAVELIFT STGB 260056. mRRinEES TRQVELIFT

Model 100BFM at Anderson Boatyard. Sausalito. CA. 3500 Ton Dock 200' x 100' 90' Between

Wing Walls 1500 Ton Dock 160' x 80' 70' Between

Wing Walls 1200 Ton Dock 140' x 60' 52' Between

Wing Walls 850 Ton Dock 60'x 150' 50' Between

Wing Walls 300 Ton Dock 50' x 80' 40' Between

Wing Walls

Circle 197 on Reader Service Card

June, 1985

MAIN IRON WORKS, INC.

REPAIR SERVICE

SERVING TUGS, PUSHERS, TOWBOATS, CREWBOATS

SUPPLY BOATS, INLAND & OFFSHORE BARGES

HISTORY

Founded in 1948, Main Iron Works, Inc s current facilities are available for construc- tion of new vessels ranging in size from 45' to 250' in length. Dry docking and a full range of repair services are also available, includ- ing a complete machine shop facility, sand- blasting and painting services.

With over thirty years experience and our record of service to the towing industry,

Main Iron Works, Inc. is ready to serve the needs of our past, present and future clients.

GENERAL SERVICES

Air control mechanics

Electrical repairs, trouble shooting

Hydraulic mechanics

Piping and plumbing repairs

Sandblasting and Painting

Complete machine shop service

A.B.S. approved for stainless steel

Cladding on main shafts

Complete woodworking shop

CONTACT:

LeRoy Molaison • Henry Brunet

Harvey Landry • Wayne Piazza (504) 876-6302 • (504) 525-4020

P.O. Bo* 1918 • Houma, LA 70361

Circle 132 on Reader

Five Dry Docks: 300-Ton Capacity 850-Ton Capacity 1200-Ton Capacity 1500-Ton Capacity 3500-Ton Capacity

Machine Shop:

Lathes: Capacity in feet - 36 Feet

Swing in Inches - 30 Inches

Wet Slips:

Three slips available for your boats or barges to tie up while repairs or supplies are being completed.

Shaft Storage Rack:

To avoid costly delays in waiting for transport of shafts, we provide our cus- tomers storage for their spare main shafts and rudder shafts.

Inventory:

Along with our parts inventory, we keep a stock of steel plates, pipe, angles, flat bars, and channels, all American Bureau of Shipping approved.

We also have a supply of forgings and bar castings which enable us to supply your needs efficiently.

All of the services listed above are avail- able on a 24-hour basis, seven days a week.

Quotations and price schedules are avail- able upon request.

Location: 50 Mile Marker, ICW, Houma, La.

Crane Service: 100 Ton Fixed Stiffleg for Offloading and

Loading Supplies.

Service Card 121

122

122

124

124