Page 48: of Maritime Reporter Magazine (January 1991)

Read this page in Pdf, Flash or Html5 edition of January 1991 Maritime Reporter Magazine

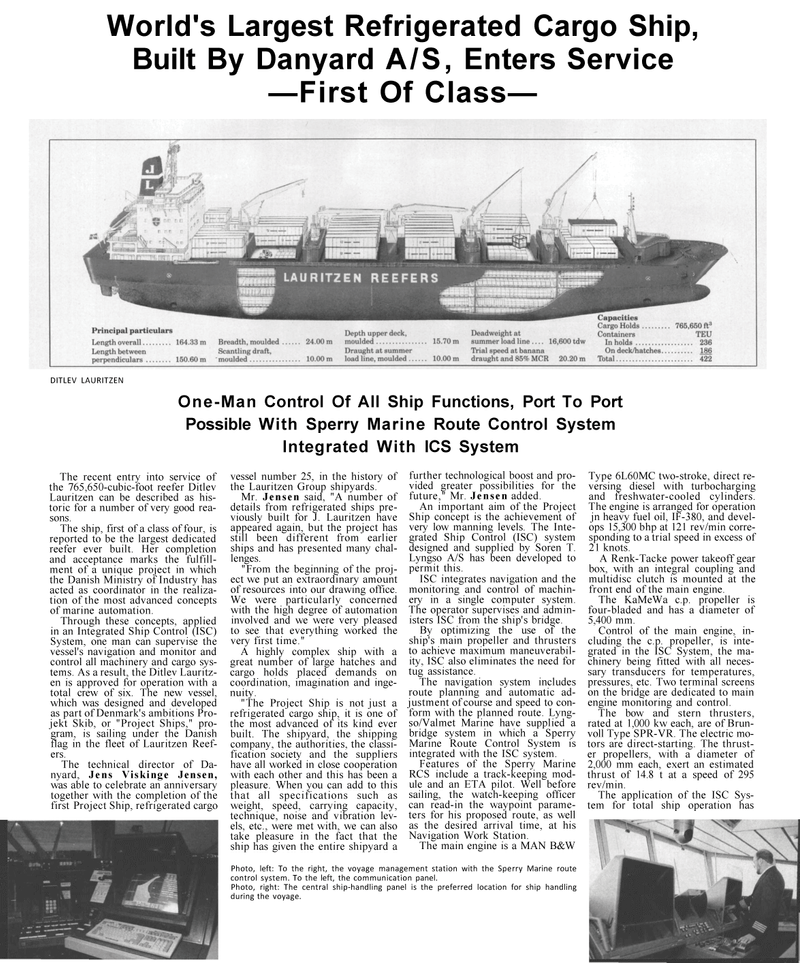

World's Largest Refrigerated Cargo Ship,

Built By Danyard A/S, Enters Service —First Of Class—

DITLEV LAURITZEN

One-Man Control Of All Ship Functions, Port To Port

Possible With Sperry Marine Route Control System

Integrated With ICS System

The recent entry into service of the 765,650-cubic-foot reefer Ditlev

Lauritzen can be described as his- toric for a number of very good rea- sons.

The ship, first of a class of four, is reported to be the largest dedicated reefer ever built. Her completion and acceptance marks the fulfill- ment of a unique project in which the Danish Ministry of Industry has acted as coordinator in the realiza- tion of the most advanced concepts of marine automation.

Through these concepts, applied in an Integrated Ship Control (ISC)

System, one man can supervise the vessel's navigation and monitor and control all machinery and cargo sys- tems. As a result, the Ditlev Lauritz- en is approved for operation with a total crew of six. The new vessel, which was designed and developed as part of Denmark's ambitions Pro- jekt Skib, or "Project Ships," pro- gram, is sailing under the Danish flag in the fleet of Lauritzen Reef- ers.

The technical director of Da- nyard, Jens Viskinge Jensen, was able to celebrate an anniversary together with the completion of the first Project Ship, refrigerated cargo vessel number 25, in the history of the Lauritzen Group shipyards.

Mr. Jensen said, "A number of details from refrigerated ships pre- viously built for J. Lauritzen have appeared again, but the project has still been different from earlier ships and has presented many chal- lenges. "From the beginning of the proj- ect we put an extraordinary amount of resources into our drawing office.

We were particularly concerned with the high degree of automation involved and we were very pleased to see that everything worked the very first time."

A highly complex ship with a great number of large hatches and cargo holds placed demands on coordination, imagination and inge- nuity. "The Project Ship is not just a refrigerated cargo ship, it is one of the most advanced of its kind ever built. The shipyard, the shipping company, the authorities, the classi- fication society and the suppliers have all worked in close cooperation with each other and this has been a pleasure. When you can add to this that all specifications such as weight, speed, carrying capacity, technique, noise and vibration lev- els, etc., were met with, we can also take pleasure in the fact that the ship has given the entire shipyard a further technological boost and pro- vided greater possibilities for the future," Mr. Jensen added.

An important aim of the Project

Ship concept is the achievement of very low manning levels. The Inte- grated Ship Control (ISC) system designed and supplied by Soren T.

Lyngso A/S has been developed to permit this.

ISC integrates navigation and the monitoring and control of machin- ery in a single computer system.

The operator supervises and admin- isters ISC from the ship's bridge.

By optimizing the use of the ship's main propeller and thrusters to achieve maximum maneuverabil- ity, ISC also eliminates the need for tug assistance.

The navigation system includes route planning and automatic ad- justment of course and speed to con- form with the planned route. Lyng- so/Valmet Marine have supplied a bridge system in which a Sperry

Marine Route Control System is integrated with the ISC system.

Features of the Sperry Marine

RCS include a track-keeping mod- ule and an ETA pilot. Well before sailing, the watch-keeping officer can read-in the waypoint parame- ters for his proposed route, as well as the desired arrival time, at his

Navigation Work Station.

The main engine is a MAN B&W

Type 6L60MC two-stroke, direct re- versing diesel with turbocharging and freshwater-cooled cylinders.

The engine is arranged for operation jn heavy fuel oil, IF-380, and devel- ops 15,300 bhp at 121 rev/min corre- sponding to a trial speed in excess of 21 knots.

A Renk-Tacke power takeoff gear box, with an integral coupling and multidisc clutch is mounted at the front end of the main engine.

The KaMeWa c.p. propeller is four-bladed and has a diameter of 5,400 mm.

Control of the main engine, in- cluding the c.p. propeller, is inte- grated in the ISC System, the ma- chinery being fitted with all neces- sary transducers for temperatures, pressures, etc. Two terminal screens on the bridge are dedicated to main engine monitoring and control.

The bow and stern thrusters, rated at 1,000 kw each, are of Brun- voll Type SPR-VR. The electric mo- tors are direct-starting. The thrust- er propellers, with a diameter of 2,000 mm each, exert an estimated thrust of 14.8 t at a speed of 295 rev/min.

The application of the ISC Sys- tem for total ship operation has

Photo, left: To the right, the voyage management station with the Sperry Marine route control system. To the left, the communication panel.

Photo, right: The central ship-handling panel is the preferred location for ship handling during the voyage.

47

47

49

49