Page 92: of Maritime Reporter Magazine (September 1992)

Read this page in Pdf, Flash or Html5 edition of September 1992 Maritime Reporter Magazine

Bender Awarded $598,613

MarAd Repair Contract

Bender Shipbuilding & Repair

Company, Inc., of Mobile, Ala., re- cently commenced work on a $598,613 U.S. Maritime Adminis- tration (MarAd) contract for the dry- docking and repair of the SS Gulf

Trader. The 495-foot by 69-foot gen- eral cargo ship is based in MarAd's

Ready Reserve Force (RRF) fleet in

Beaumont, Texas. The work will be performed in 20 days and employ 50 workers.

Bender is a full-service shipyard that has built, converted and re- paired vessels for commercial and governmental owners and opera- tors for more than 70 years.

To receive free information about the services and facilities available from Bender Shipbuilding & Re- pair,

Circle 5 on Reader Service Card

ABS Reorganizes Its

European Division

It was recently announced by

Robert D. Somerville, the presi- dent and CEO of the American Bu- reau of Shipping's (ABS's) European division, one of the classification society's three marine operating di- visions, that ABS Europe had been reorganized. "Due to the increasing involvement and prominence of the

How to Operate More Efficiently At Lower

Cost With Tranter Plate-type Heat Exchangers

HEAT RECOVERY FROM CONDENSATE » CONDENSAT

DESALINATION

UNIT

COOLING ELECTRONIC

GEAR

HEATING RECOVERED OIL

STEAM

HEATED TANK FOR

BANK RECOVERED OIL

SPILLS

SEAWATER ! : "1

SEAWATER SUPERCHANGER

UNIT

CENTRAL FRESH

WATER COOLER

SEAWATER OR

FRESH WATER

SUPERCHANGER

UNIT

TO VARIOUS

USE POINTS

FRESH WATER

STORAGE TANK

SUPERCHANGER

UNIT

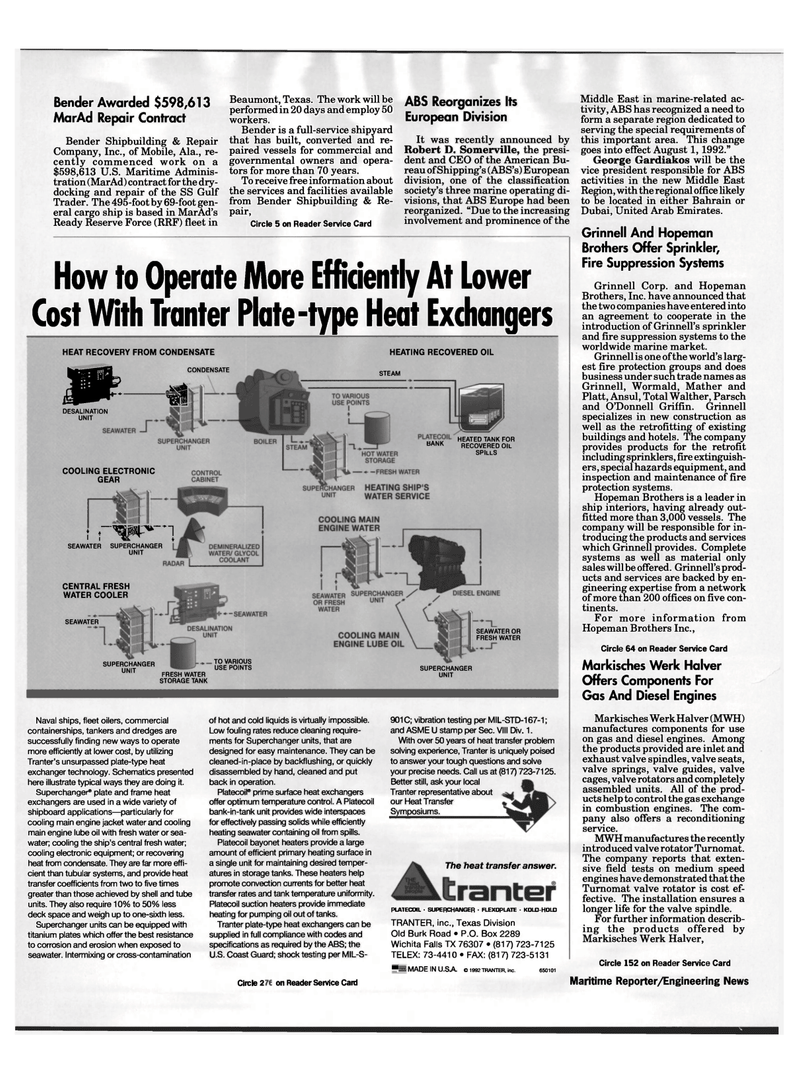

Naval ships, fleet oilers, commercial containerships, tankers and dredges are successfully finding new ways to operate more efficiently at lower cost, by utilizing

Tranter's unsurpassed plate-type heat exchanger technology. Schematics presented here illustrate typical ways they are doing it.

Superchanger® plate and frame heat exchangers are used in a wide variety of shipboard applications—particularly for cooling main engine jacket water and cooling main engine lube oil with fresh water or sea- water; cooling the ship's central fresh water; cooling electronic equipment; or recovering heat from condensate. They are far more effi- cient than tubular systems, and provide heat transfer coefficients from two to five times greater than those achieved by shell and tube units. They also require 10% to 50% less deck space and weigh up to one-sixth less.

Superchanger units can be equipped with titanium plates which offer the best resistance to corrosion and erosion when exposed to seawater. Intermixing or cross-contamination of hot and cold liquids is virtually impossible.

Low fouling rates reduce cleaning require- ments for Superchanger units, that are designed for easy maintenance. They can be cleaned-in-place by backflushing, or quickly disassembled by hand, cleaned and put back in operation.

Platecoil® prime surface heat exchangers offer optimum temperature control. A Platecoil bank-in-tank unit provides wide interspaces for effectively passing solids while efficiently heating seawater containing oil from spills.

Platecoil bayonet heaters provide a large amount of efficient primary heating surface in a single unit for maintaining desired temper- atures in storage tanks. These heaters help promote convection currents for better heat transfer rates and tank temperature uniformity.

Platecoil suction heaters provide immediate heating for pumping oil out of tanks.

Tranter plate-type heat exchangers can be supplied in full compliance with codes and specifications as required by the ABS; the

U.S. Coast Guard; shock testing per MIL-S- 94 Circle 203 on Reader Service Card 901C; vibration testing per MIL-STD-167-1; and ASME U stamp per Sec. VIII Div. 1.

With over 50 years of heat transfer problem solving experience, Tranter is uniquely poised to answer your tough questions and solve your precise needs. Call us at (817) 723-7125.

Better still, ask your local

Tranter representative about our Heat Transfer

Symposiums. (817)723-7125.

The heat transfer answer.

PLATECOIL • SUPERCHANGER • FLEXOPLATE • KOLD-HOLD

TRANTER, inc., Texas Division

Old Burk Road • P.O. Box 2289

Wichita Falls TX 76307 • (817) 723-7125

TELEX: 73-4410 • FAX: (817) 723-5131

M MADE IN U.S.A. © 1992 TRANTER, inc. 650101

Middle East in marine-related ac- tivity, ABS has recognized a need to form a separate region dedicated to serving the special requirements of this important area. This change goes into effect August 1, 1992."

George Gardiakos will be the vice president responsible for ABS activities in the new Middle East

Region, with the regional office likely to be located in either Bahrain or

Dubai, United Arab Emirates.

Grinnell And Hopeman

Brothers Offer Sprinkler,

Fire Suppression Systems

Grinnell Corp. and Hopeman

Brothers, Inc. have announced that the two companies have entered into an agreement to cooperate in the introduction of Grinnell's sprinkler and fire suppression systems to the worldwide marine market.

Grinnell is one of the world's larg- est fire protection groups and does business under such trade names as

Grinnell, Wormald, Mather and

Piatt, Ansul, Total Walther, Parsch and O'Donnell Griffin. Grinnell specializes in new construction as well as the retrofitting of existing buildings and hotels. The company provides products for the retrofit including sprinklers, fire extinguish- ers, special hazards equipment, and inspection and maintenance of fire protection systems.

Hopeman Brothers is a leader in ship interiors, having already out- fitted more than 3,000 vessels. The company will be responsible for in- troducing the products and services which Grinnell provides. Complete systems as well as material only sales will be offered. Grinnell's prod- ucts and services are backed by en- gineering expertise from a network of more than 200 offices on five con- tinents.

For more information from

Hopeman Brothers Inc.,

Circle 64 on Reader Service Card

Markisches Werk Halver

Offers Components For

Gas And Diesel Engines

Markisches Werk Halver (MWH) manufactures components for use on gas and diesel engines. Among the products provided are inlet and exhaust valve spindles, valve seats, valve springs, valve guides, valve cages, valve rotators and completely assembled units. All of the prod- ucts help to control the gas exchange in combustion engines. The com- pany also offers a reconditioning service.

MWH manufactures the recently introduced valve rotator Turnomat.

The company reports that exten- sive field tests on medium speed engines have demonstrated that the

Turnomat valve rotator is cost ef- fective. The installation ensures a longer life for the valve spindle.

For further information describ- ing the products offered by

Markisches Werk Halver,

Circle 152 on Reader Service Card

Maritime Reporter/Engineering News

91

91

93

93