Page 93: of Maritime Reporter Magazine (September 1992)

Read this page in Pdf, Flash or Html5 edition of September 1992 Maritime Reporter Magazine

Cover Story

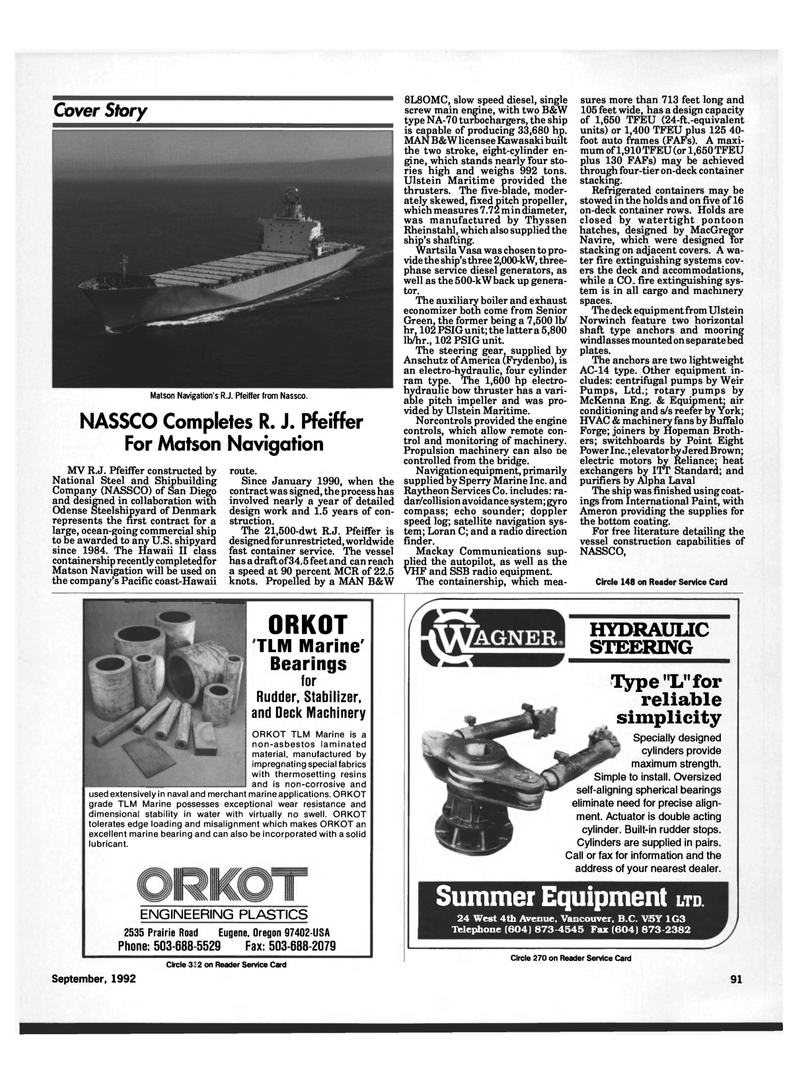

Matson Navigation's R.J. Pfeiffer from Nassco.

NASSCO Completes R. J. Pfeiffer

For Matson Navigation

MV R.J. Pfeiffer constructed by

National Steel and Shipbuilding

Company (NASSCO) of San Diego and designed in collaboration with

Odense Steelshipyard of Denmark represents the first contract for a large, ocean-going commercial ship to be awarded to any U.S. shipyard since 1984. The Hawaii II class container ship recently completed for

Matson Navigation will be used on the company's Pacific coast-Hawaii route.

Since January 1990, when the contract was signed, the process has involved nearly a year of detailed design work and 1.5 years of con- struction.

The 21,500-dwt R.J. Pfeiffer is designed for unrestricted, worldwide fast container service. The vessel has a draft of 34.5 feet and can reach a speed at 90 percent MCR of 22.5 knots. Propelled by a MAN B&W 8L80MC, slow speed diesel, single screw main engine, with two B&W type NA-70 turbochargers, the ship is capable of producing 33,680 hp.

MAN B&W licensee Kawasaki built the two stroke, eight-cylinder en- gine, which stands nearly four sto- ries high and weighs 992 tons.

Ulstein Maritime provided the thrusters. The five-blade, moder- ately skewed, fixed pitch propeller, which measures 7.72 min diameter, was manufactured by Thyssen

Rheinstahl, which also supplied the ship's shafting.

Wartsila Vasa was chosen to pro- vide the ship's three 2,000-kW, three- phase service diesel generators, as well as the 500-kWback up genera- tor.

The auxiliary boiler and exhaust economizer both come from Senior

Green, the former being a 7,500 lb/ hr, 102 PSIGunit; the latter a 5,800 lb/hr., 102 PSIG unit.

The steering gear, supplied by

Anschutz of America (Frydenbo), is an electro-hydraulic, four cylinder ram type. The 1,600 hp electro- hydraulic bow thruster has a vari- able pitch impeller and was pro- vided by Ulstein Maritime.

Norcontrols provided the engine controls, which allow remote con- trol and monitoring of machinery.

Propulsion machinery can also De controlled from the bridge.

Navigation equipment, primarily supplied by Sperry Marine Inc. and

Raytheon Services Co. includes: ra- dar/collision avoidance system; gyro compass; echo sounder; doppler speed log; satellite navigation sys- tem; Loran C; and a radio direction finder.

Mackay Communications sup- plied the autopilot, as well as the

VHF and SSB radio equipment.

The containership, which mea- sures more than 713 feet long and 105 feet wide, has a design capacity of 1,650 TFEU (24-ft.-equivalent units) or 1,400 TFEU plus 125 40- foot auto frames (FAFs). A maxi- mum of 1,910 TFEU (or 1,650 TFEU plus 130 FAFs) may be achieved through four-tier on-deck container stacking.

Refrigerated containers may be stowed in the holds and on five of 16 on-deck container rows. Holds are closed by watertight pontoon hatches, designed by MacGregor

Navire, which were designed for stacking on adjacent covers. A wa- ter fire extinguishing systems cov- ers the deck and accommodations, while a CO fire extinguishing sys- tem is in all cargo and machinery spaces.

The deck equipment from Ulstein

Norwinch feature two horizontal shaft type anchors and mooring windlasses mounted on separate bed plates.

The anchors are two lightweight

AC-14 type. Other equipment in- cludes: centrifugal pumps by Weir

Pumps, Ltd.; rotary pumps by

McKenna Eng. & Equipment; air conditioning and s/s reefer by York;

HVAC & machinery fans by Buffalo

Forge; joiners by Hopeman Broth- ers; switchboards by Point Eight

Power Inc.; elevator by Jered Brown; electric motors by Reliance; heat exchangers by ITT Standard; and purifiers by Alpha Laval

The ship was finished using coat- ings from International Paint, with

Ameron providing the supplies for the bottom coating.

For free literature detailing the vessel construction capabilities of

NASSCO,

Circle 148 on Reader Service Card 0RK0T

TLM Marine'

Bearings for

Rudder, Stabilizer, and Deck Machinery

HYDRAULIC

STEERING

ORKOT TLM Marine is a non-asbestos laminated material, manufactured by impregnating special fabrics with thermosetting resins and is non-corrosive and used extensively in naval and merchant marine applications. ORKOT grade TLM Marine possesses exceptional wear resistance and dimensional stability in water with virtually no swell. ORKOT tolerates edge loading and misalignment which makes ORKOT an excellent marine bearing and can also be incorporated with a solid lubricant.

Type "L" for reliable simplicity

Specially designed cylinders provide maximum strength.

Simple to install. Oversized self-aligning spherical bearings eliminate need for precise align- ment. Actuator is double acting cylinder. Built-in rudder stops.

Cylinders are supplied in pairs.

Call or fax for information and the address of your nearest dealer.

Summer Equipment LTD. 24 West 4th Avenue, Vancouver, B.C. V5Y 1G3

Telephone (604) 873-4545 Fax (604) 873-2382

ENGINEERING PLASTICS 2535 Prairie Road Eugene, Oregon 97402-USA

Phone: 503-688-5529 Fax: 503-688-2079

Circle 324 on Reader Service Card

September, 1992

Circle 270 on Reader Service Card 91

92

92

94

94