Page 71: of Maritime Reporter Magazine (January 1994)

Read this page in Pdf, Flash or Html5 edition of January 1994 Maritime Reporter Magazine

Haldor Topsoe A/S:

A Leader In NOx Reduction

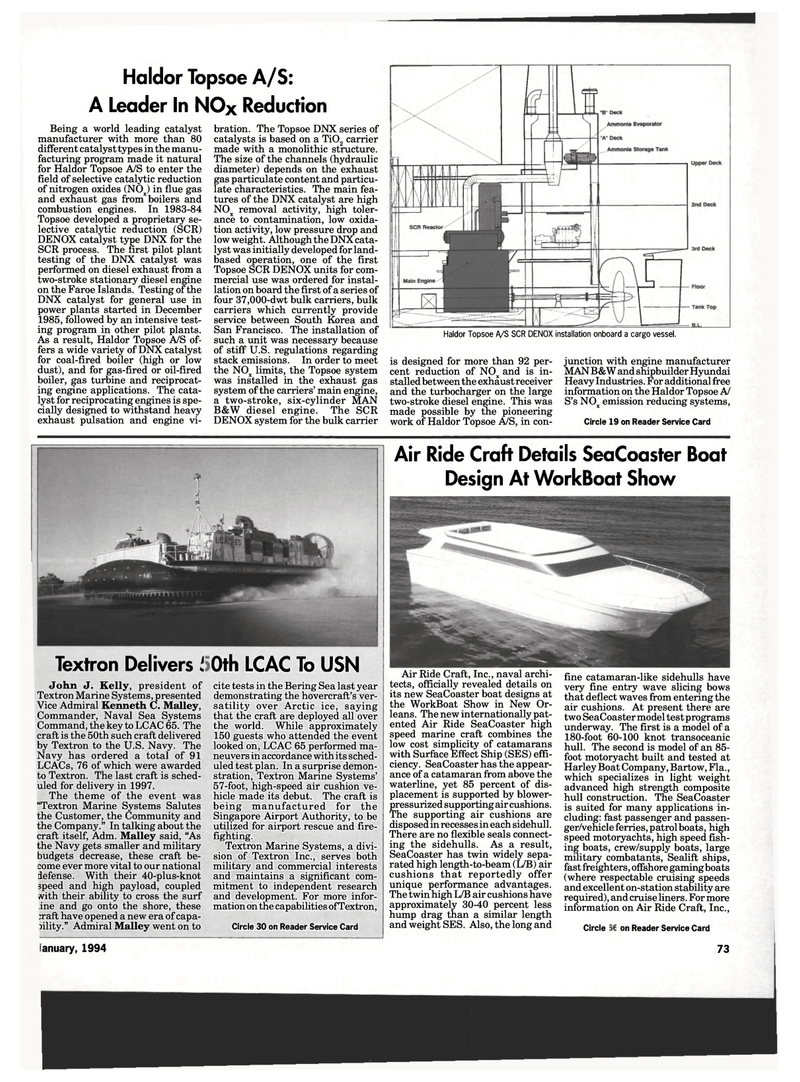

Haldor Topsoe A/S SCR DENOX installation onboard a cargo vessel.

Being a world leading catalyst manufacturer with more than 80 different catalyst types in the manu- facturing program made it natural for Haldor Topsoe A/S to enter the field of selective catalytic reduction of nitrogen oxides (NOx) in flue gas and exhaust gas from boilers and combustion engines. In 1983-84

Topsoe developed a proprietary se- lective catalytic reduction (SCR)

DENOX catalyst type DNX for the

SCR process. The first pilot plant testing of the DNX catalyst was performed on diesel exhaust from a two-stroke stationary diesel engine on the Faroe Islands. Testing of the

DNX catalyst for general use in power plants started in December 1985, followed by an intensive test- ing program in other pilot plants.

As a result, Haldor Topsoe A/S of- fers a wide variety of DNX catalyst for coal-fired boiler (high or low dust), and for gas-fired or oil-fired boiler, gas turbine and reciprocat- ing engine applications. The cata- lyst for reciprocating engines is spe- cially designed to withstand heavy exhaust pulsation and engine vi- bration. The Topsoe DNX series of catalysts is based on a Ti02 carrier made with a monolithic structure.

The size of the channels (hydraulic diameter) depends on the exhaust gas particulate content and particu- late characteristics. The main fea- tures of the DNX catalyst are high

NOx removal activity, high toler- ance to contamination, low oxida- tion activity, low pressure drop and low weight. Although the DNX cata- lyst was initially developed for land- based operation, one of the first

Topsoe SCR DENOX units for com- mercial use was ordered for instal- lation on board the first of a series of four 37,000-dwt bulk carriers, bulk carriers which currently provide service between South Korea and

San Francisco. The installation of such a unit was necessary because of stiff U.S. regulations regarding stack emissions. In order to meet the NOx limits, the Topsoe system was installed in the exhaust gas system of the carriers' main engine, a two-stroke, six-cylinder MAN

B&W diesel engine. The SCR

DENOX system for the bulk carrier is designed for more than 92 per- cent reduction of NOx and is in- stalled between the exhaust receiver and the turbocharger on the large two-stroke diesel engine. This was made possible by the pioneering work of Haldor Topsoe A/S, in con- junction with engine manufacturer

MAN B&W and shipbuilder Hyundai

Heavy Industries. For additional free information on the Haldor Topsoe A/

S's NOx emission reducing systems,

Circle 19 on Reader Service Card

January, 1994

Air Ride Craft Details SeaCoaster Boat

Design At WorkBoat Show

Air Ride Craft, Inc., naval archi- tects, officially revealed details on its new SeaCoaster boat designs at the WorkBoat Show in New Or- leans. The new internationally pat- ented Air Ride SeaCoaster high speed marine craft combines the low cost simplicity of catamarans with Surface Effect Ship (SES) effi- ciency. SeaCoaster has the appear- ance of a catamaran from above the waterline, yet 85 percent of dis- placement is supported by blower- pressurized supporting air cushions.

The supporting air cushions are disposed in recesses in each sidehull.

There are no flexible seals connect- ing the sidehulls. As a result,

SeaCoaster has twin widely sepa- rated high length-to-beam (L/B) air cushions that reportedly offer unique performance advantages.

The twin high L/B air cushions have approximately 30-40 percent less hump drag than a similar length and weight SES. Also, the long and fine catamaran-like sidehulls have very fine entry wave slicing bows that deflect waves from entering the air cushions. At present there are two SeaCoaster model test programs underway. The first is a model of a 180-foot 60-100 knot transoceanic hull. The second is model of an 85- foot motoryacht built and tested at

Harley Boat Company, Bartow, Fla., which specializes in light weight advanced high strength composite hull construction. The SeaCoaster is suited for many applications in- cluding: fast passenger and passen- ger/vehicle ferries, patrol boats, high speed motoryachts, high speed fish- ing boats, crew/supply boats, large military combatants, Sealift ships, fast freighters, offshore gaming boats (where respectable cruising speeds and excellent on-station stability are required), and cruise liners. For more information on Air Ride Craft, Inc.,

Circle 297 on Reader Service Card 73

Textron Delivers I

John J. Kelly, president of

Textron Marine Systems, presented

Vice Admiral Kenneth C. Malley,

Commander, Naval Sea Systems

Command, the key to LCAC 65. The craft is the 50th such craft delivered by Textron to the U.S. Navy. The

Navy has ordered a total of 91

LCACs, 76 of which were awarded to Textron. The last craft is sched- uled for delivery in 1997.

The theme of the event was "Textron Marine Systems Salutes the Customer, the Community and the Company." In talking about the craft itself, Adm. Malley said, "As the Navy gets smaller and military budgets decrease, these craft be- come ever more vital to our national defense. With their 40-plus-knot speed and high payload, coupled ivith their ability to cross the surf ine and go onto the shore, these ;raft have opened a new era of capa-

Dility." Admiral Malley went on to 0th LCAC To USN cite tests in the Bering Sea last year demonstrating the hovercraft's ver- satility over Arctic ice, saying that the craft are deployed all over the world. While approximately 150 guests who attended the event looked on, LCAC 65 performed ma- neuvers in accordance with its sched- uled test plan. In a surprise demon- stration, Textron Marine Systems' 57-foot, high-speed air cushion ve- hicle made its debut. The craft is being manufactured for the

Singapore Airport Authority, to be utilized for airport rescue and fire- fighting.

Textron Marine Systems, a divi- sion of Textron Inc., serves both military and commercial interests and maintains a significant com- mitment to independent research and development. For more infor- mation on the capabilities of Textron,

Circle 30 on Reader Service Card

70

70

72

72