Page 63: of Maritime Reporter Magazine (May 1994)

Read this page in Pdf, Flash or Html5 edition of May 1994 Maritime Reporter Magazine

MARINE

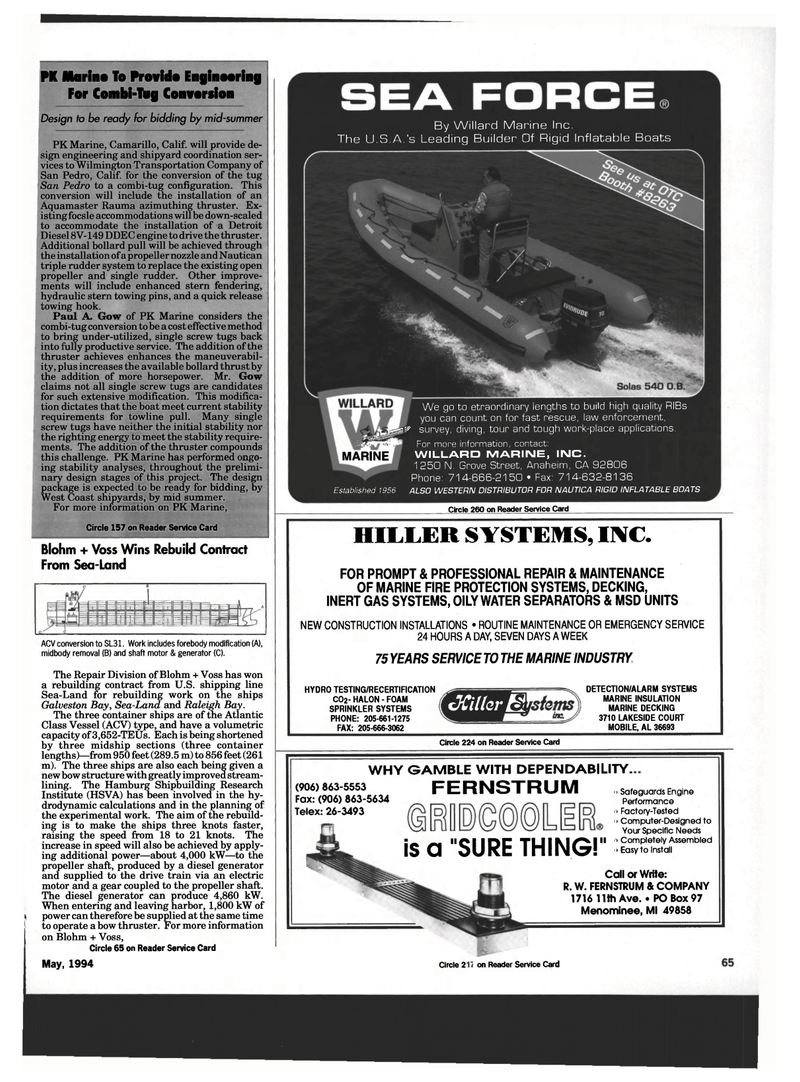

We go to etraordinary lengths to build high quality RIBs you can count on for fast rescue, law enforcement, 3* survey, diving, tour and tough work-place applications.

For more information, contact:

WILLARD MARINE, INC. 1250 N. Grove Street, Anaheim, CA 92806

Phone: 714-666-2150 • Fax: 714-632-8136

Established 1956 ALSO WESTERN DISTRIBUTOR FOR NAUTICA RIGID INFLATABLE BOATS

HILLER SYSTEMS, INC.

FOR PROMPT & PROFESSIONAL REPAIR & MAINTENANCE

OF MARINE FIRE PROTECTION SYSTEMS, DECKING,

INERT GAS SYSTEMS, OILY WATER SEPARATORS & MSD UNITS

NEW CONSTRUCTION INSTALLATIONS • ROUTINE MAINTENANCE OR EMERGENCY SERVICE 24 HOURS A DAY, SEVEN DAYS A WEEK 75 YEARS SERVICE TO THE MARINE INDUSTRY

HYDRO TESTING/RECERTIFICATION

C02-HALON- FOAM

SPRINKLER SYSTEMS

PHONE: 205-661-1275

FAX: 205-666-3062

JCilkrM

DETECTION/ALARM SYSTEMS

MARINE INSULATION

MARINE DECKING 3710 LAKESIDE COURT

MOBILE, AL 36693

By Willard Marine Inc.

The U.S.A.'s Leading Builder Of Rigid Inflatable Boats

Blohm + Voss Wins Rebuild Contract

From Sea-Land

PK Marine To Provide Engineering

For Combi-ltig Conversion

Design to be ready for bidding by mid-summer

PK Marine, Camarillo, Calif, will provide de- sign engineering and shipyard coordination ser- vices to Wilmington Transportation Company of

San Pedro, Calif, for the conversion of the tug

San Pedro to a combi-tug configuration. This conversion will include the installation of an

Aquamaster Rauma azimuthing thruster. Ex- isting focsle accommodations will be down-scaled to accommodate the installation of a Detroit

Diesel 8V-149 DDEC engine to drive the thruster.

Additional bollard pull will be achieved through the installation of a propeller nozzle and Nautican triple rudder system to replace the existing open propeller and single rudder. Other improve- ments will include enhanced stern fendering, hydraulic stern towing pins, and a quick release towing hook.

Paul A. Gow of PK Marine considers the combi-tug conversion to be a cost effective method to bring under-utilized, single screw tugs back into fully productive service. The addition of the thruster achieves enhances the maneuverabil- ity, plus increases the available bollard thrust by the addition of more horsepower. Mr. Gow claims not all single screw tugs are candidates for such extensive modification. This modifica- tion dictates that the boat meet current stability requirements for towline pull. Many single screw tugs have neither the initial stability nor the righting energy to meet the stability require- ments. The addition of the thruster compounds this challenge. PK Marine has performed ongo- ing stability analyses, throughout the prelimi- nary design stages of this project. The design package is expected to be ready for bidding, by

West Coast shipyards, by mid summer.

For more information on PK Marine,

Circle 157 on Reader Service Card

ACV conversion to SL31. Work includes forebody modification (A), midbody removal (B) and shaft motor & generator (C).

The Repair Division of Blohm + Voss has won a rebuilding contract from U.S. shipping line

Sea-Land for rebuilding work on the ships

Galveston Bay, Sea-Land and Raleigh Bay.

The three container ships are of the Atlantic

Class Vessel (ACV) type, and have a volumetric capacity of3,652-TEUs. Each is being shortened by three midship sections (three container lengths)—from 950 feet (289.5 m) to 856 feet (261 m). The three ships are also each being given a new bow structure with greatly improved stream- lining. The Hamburg Shipbuilding Research

Institute (HSVA) has been involved in the hy- drodynamic calculations and in the planning of the experimental work. The aim of the rebuild- ing is to make the ships three knots faster, raising the speed from 18 to 21 knots. The increase in speed will also be achieved by apply- ing additional power—about 4,000 kW—to the propeller shaft, produced by a diesel generator and supplied to the drive train via an electric motor and a gear coupled to the propeller shaft.

The diesel generator can produce 4,860 kW.

When entering and leaving harbor, 1,800 kW of \ power can therefore be supplied at the same time to operate a bow thruster. For more information on Blohm + Voss,

Circle 65 on Reader Service Card

May, 1994

Circle 260 on Reader Service Card

Circle 224 on Reader Service Card

Circle 238 on Reader Service Card 65

Call or Write:

R. W. FERNSTRUM & COMPANY 1716 11th Ave. • PO Box 97

Menominee, Ml 49858

WHY GAMBLE WITH DEPENDABILITY. (906) 863-5553

Fax: (906) 863-5634

Telex: 26-3493

FERNSTRUM is a "SURE THING!" i Safeguards Engine

Performance > Factory-Tested > Computer-Designed to

Your Specific Needs > Completely Assembled > Easy to Install

62

62

64

64