Page 48: of Maritime Reporter Magazine (October 1998)

Read this page in Pdf, Flash or Html5 edition of October 1998 Maritime Reporter Magazine

Software Solutions; CAD/CAM/CAE

ERAM Draws To Conclusion At DTMB

For more than a year, Maritime

Reporter & Engineering News has tracked the progress of a multi- national team working to develop an optimized engine room arrange- ment. This is the final article in a four-part series describing the pro- ject executed by the U.S. Navy in partnership with domestic and international shipyards, shipown- er/operators and marine equip- ment vendors.

As mentioned in the first article, the project was an Engine Room

Arrangement Model (ERAM) study, sponsored by the Mid-Term

Strategic Sealift Technology

Development Program (MTSST-

DP) and orchestrated by the

Shipbuilding Technology

Department of the David Taylor

Model Basin (DTMB).

The vision of the project was to initiate a customer-focused process that would enable the U.S. ship- building industry to design and build engine rooms that would pro- mote internationally competitive commercial ships. The objectives were: • To provide a forum for U.S. shipbuilders to present their views and needs for product and process design. • Within 12 months, develop a process using Integrated Process and Product Development (IPPD) for industry use, to design engine room arrangements that provides the basis for the design of interna- tionally competitive commercial

ERAM (core) team participants for the SSD#3 design were:

Country

U.S.

U.S.

U.S.

U.S.

Brazil

U.S.

U.S.

U.S.

U.S.

U.S.

Denmark

Company

D&P

D&P

DTMB

Avondale Shipyard

CONSUNAV

D&P

D&P

Bath Iron Works

D&P

NASSCO

Brix & Kamp A/S

Name

Richard DeVries

Dan Gallagher

Ben Kassel

Watson Perrin, II

Jorge Ribeiro

Kevin Prince

Frank Woronkowicz

Mark Cote

Jack Guilfoyle

Lee Duneclift

Morton Sandvej

Expertise

Team Leader

Structure

MIS Manager

Arrangements & HVAC

Arrangements & Piping

Arrangements & Metrics

Control Systems

Arrangements & Piping

Electrical

Arrangements & Piping

Arrangements & Piping

CAD Team participants were:

Rusty Dupont

Chris Jones

Gene Rice

Paul Rakow

Jesse Rose

Bob Ramsey

Jake Robinson

Nancy Russell

InfoTech

InfoTech

InfoTech

D&P

JJMA

NAVSEA

D&P

NSWCCD

Other resources/expertise utilized on a part-time or rotating basis included: A&T/Vector Research (man- agement consulting); Alfa Laval (fuel treatment);

Allweiler (pumps); Boll & Kirch (filters and strainers);

Crowley Marine (ship operator); D&P (electrical and structural engineering); Maersk Lines (ship opera- tor); and Tranter (heat exchangers). ships. • Within 24 months, to demonstrate the process by design- ing three (later increased to four) world-class engine room arrange- ments. • To achieve customer-focus and buy-in of product design. • To achieve U.S. shipbuild- ing industry-focus and buy-in of process design. • To establish baseline com- mercial ship engine room designs as benchmarks for evaluation of future government-initiated stud- ies. • To document both the prod- uct and process design with ratio- nale for use and further refine-

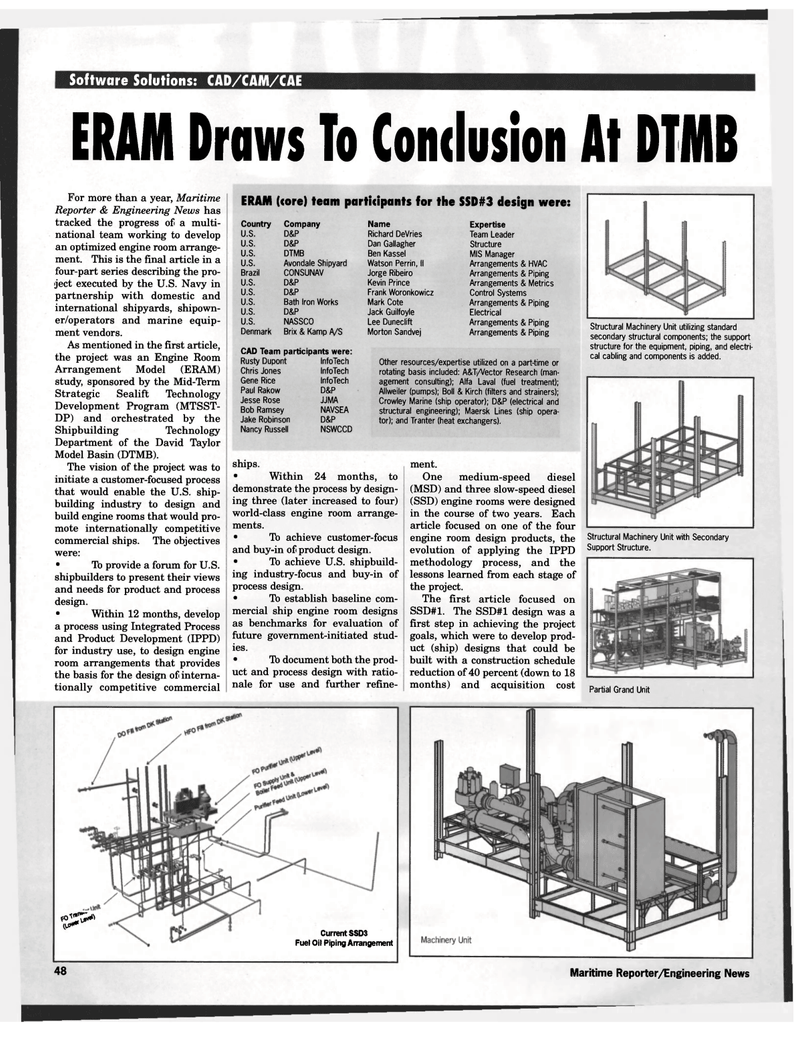

Structural Machinery Unit utilizing standard secondary structural components; the support structure for the equipment, piping, and electri- cal cabling and components is added. ment.

One medium-speed diesel (MSD) and three slow-speed diesel (SSD) engine rooms were designed in the course of two years. Each article focused on one of the four engine room design products, the evolution of applying the IPPD methodology process, and the lessons learned from each stage of the project.

The first article focused on

SSD#1. The SSD#1 design was a first step in achieving the project goals, which were to develop prod- uct (ship) designs that could be built with a construction schedule reduction of 40 percent (down to 18 months) and acquisition cost

Structural Machinery Unit with Secondary

Support Structure.

Partial Grand Unit fO^V1 tyo*"

Current SSD3

Fuel Oil Piping Arrangement 48 Maritime Reporter/Engineering News

47

47

49

49