Page 26: of Maritime Reporter Magazine (December 1998)

Read this page in Pdf, Flash or Html5 edition of December 1998 Maritime Reporter Magazine

Breaking New Ground

I ft. see r/fojte */ reut. STZoervAg-

FKjo&e */! - s*/) l c *2. fg* LC*Sl

F KiOB.tr tfiwevhe*) fWUfct •»!? fUL ft** BOTTOM tfofiirx/ivs OC£AU nz

HVfl zrjiess CohtcuJL*

Maritrans Is

Making Waves

First phase of innovative double hull initiative kicks off at Tampa Bay

Shipbuilding

Maritrans 192

Shipbuilder Tampa Bay Shipbuilding

Vessel type Double hull barge (Rebuild)

Owner/ operator Maritrans Operating Partners LP.

Conversions, retrofits, and rebuilds usually do not make Maritime Reporter's list of "Great

Ships" but in this case we are pleased to make an exception.

Maritrans Operating Partners L.P. has suc- cessfully accomplished the installation of a dou- ble hull on its super barge Maritrans 192 (for- merly Ocean 192). Based on an innovative design concept by the firm of Schuler and Allen, the construction was accomplished by Tampa

Bay Shipbuilding in partnership with Mari- trans' own technical staff. Re-christening of the

Maritrans 192 was performed on November 9, 1998, by Mrs. Kay Loy, wife of U.S. Coast

Guard Commandant Admiral James Loy.

Admiral Loy was the main speaker at the fes- tive occasion.

The rebuild merits coverage under the Great

Ships banner as much for its economical sense as its technical merit. While an exact figure was not readily available, the cost of the con- version was in the neighborhood of $10 million dollars, less than half the cost of a new barge fitted similarly to the Maritrans 192. "As far as we can tell, this is the first rebuild from single hull to double hull anywhere in the

Its 28

JL

Maritime Reporter & Engineering News world," said Tom

Hagner, double hull program manager for

Maritrans. "People have talked about fit- ting external double hulls, but we are much more comfortable with

Maritrans' internal rebuild concept. The cargo is completely protected by new steel, and we believe that many metallurgical problems involving the containment structure are avoided." Hagner adds that "the struc- ture and coating of the original barge, which now makes up the con- verted barge's ballast tanks, was in superb condition. It is also useful that the major dimensions and hull hydrody- namic characteristics are unchanged so that the vessel can continue to serve the same cus- tomers."

The Internal Refit Concept

The basic design concept is to use as much of the existing barge as possible to integrate smoothly with the entirely new internal double hull. The first step was a detailed inside mea- surement to detect changes from the design to

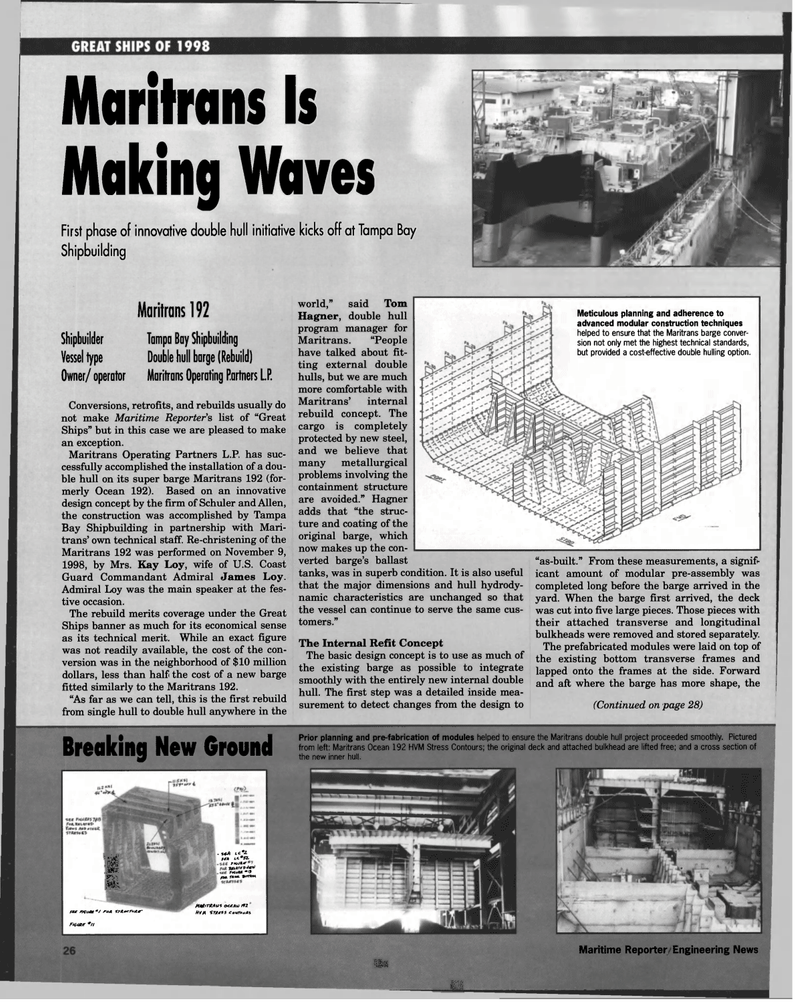

Meticulous planning and adherence to advanced modular construction techniques helped to ensure that the Maritrans barge conver- sion not only met the highest technical standards, but provided a cost-effective double hulling option. "as-built." From these measurements, a signif- icant amount of modular pre-assembly was completed long before the barge arrived in the yard. When the barge first arrived, the deck was cut into five large pieces. Those pieces with their attached transverse and longitudinal bulkheads were removed and stored separately.

The prefabricated modules were laid on top of the existing bottom transverse frames and lapped onto the frames at the side. Forward and aft where the barge has more shape, the (Continued on page 28)

Prior planning and pre-fabrication of modules helped to ensure the Maritrans double hull project proceeded smoothly. Pictured from left: Maritrans Ocean 192 HVM Stress Contours; the original deck and attached bulkhead are lifted free; and a cross section of the new inner hull.

25

25

27

27