Page 52: of Maritime Reporter Magazine (December 1998)

Read this page in Pdf, Flash or Html5 edition of December 1998 Maritime Reporter Magazine

GREAT SHIPS OF 1998

IHI's P&O Nedlloyd Southampton (Continued from page 41) population of RTA84C container- ship engines, but in a bank of cav- ernous cylinders of 960-mm bore and 2,500-mm stroke.

Reliability was a focus for the

RTA96C development project, given the nature of market demand which has sought single- engine solutions to ever-greater power and speed combinations.

Each of the engines for the P&O

Nedlloyd ships has been manufac- tured in Japan by Diesel United, a longstanding licensee of Wartsila

NSD and its predecessors.

Depending on draft and environ- mental conditions, the plant and underwater hull form enable the ship to make 25 knots if required.

It is estimated that an average passage speed of 22.8 knots is needed so as to maintain the demanding schedule. While this means that a fast, sustainable speed is vitally important, it equal- ly signifies that there must be suf- ficient power reserve in the instal- lation to enable any lost time to be made up.

Although the Loop One timetable entails a rationalized port itinerary, the knock-on effect of any delays due to terminal or mechanical problems, or especially inclement weather, could be con- siderable, and P&O Nedlloyd

Southampton has accordingly been engineered to minimize the risk and maximize the operating per- formance.

Scale commensurate to that of the prime mover is reflected in the 94.5-ton Lips propeller, claimed to be the heaviest design ever cast, and in the 3.5-MW shaft generator, jSgpfir §9 Ijr certainly one of the largest units of its kind worldwide, and an impos- ing part of the electrical power out- fit supplied by the U.K. firm Brush

Electrical Machines. The ship employs a mighty, 2,600-kW

Kawasaki bowthruster, given the and Falls Stop

Where SlipNot® Safety

Flooring Starts. © W.S. Molnar Company

Falls are the . __ ^^^^^^ number one

J? ' worker acci- / J i ' 1 ^ [>J I dent. Let us /v.. /N > SAFETY FLOORING help yOU QCt 3 grip on this problem.

SlipNofs unique Safety Flooring is an anti-slip, non-gritted Grip Plate® or Grip Grate®, available in steel, stainless steel or aluminum.

It is USDA and FDA approved and does not wear, polish or flake-off. It exceeds OSHA and

UL safety standards and is fire-proof and toxic-fume free.

Apply new or to retrofit floors, stairs, ladders, decks, pit covers, ramps, walkways, platforms, etc.

See why SlipNot® Safety Flooring outlasts all competitive materials; call, today, for free sample & complete information: 1-888-SLIPNOT slipnot.com

E-mail: [email protected]

S/ypNOT-

J SAFETY FLOORING

U.S. Patent No.s 4961973, 5077137

SlipNot Safety Flooring Division

W.S. Molnar Company 2545 Beaufait St., Detroit, Ml 48207 (313) 923-0400 Fax (313) 923-4555

Circle 286 on Reader Service Card

SAFETYPRODUCTS

INT'L CORP.

Metal Manufacturing Division

Aluminum/Steel

Ship -k Gangways (portable) -k Incline Ladders • Accommodation Ladders it Bullwark Ladders (in stock)

Barge • Beam Type Gangways, Ladders (Dist. for Louisville Ladder)

Handicapped Access •k Ramps - Engineering Available -k Pier Stands

Fiberglass Manufacturing Division -k Fire Hose Cabinets -k Lifejacket Storage Boxes •k Fire Ext. Cabinets -k Immersion Suit Cabinets •k Signal Boxes * Oil Boom & Absorbent Storage Boxes •k Fiberglass Gratings (Dist. for Creative Pultrusions)

Nautical Safety Products Intl.

P.O. Box 590462

Houston, Texas 77259-0462

Ph: (713) 643-7570

Fax: (281) 286-9751 Fax: (713) 643-6975

Many Items In Stock For Immediate Shipment

All Major Credit Cards Accepted

Circle 271 on Reader Service Card

OFFSHORE CRANES

SCHILLER INTERNATIONAL CORPORATION, 101 Eaton St, Suite 300

Hampton, VA 23669

Telephone (757) 787-0700, Fax (757) 727-0993

Circle 272 on Reader Service Card requirement for swinging and maneuvering such a broad hull with substantial windage in restricted waters.

Circle 33 on Reader Service Card

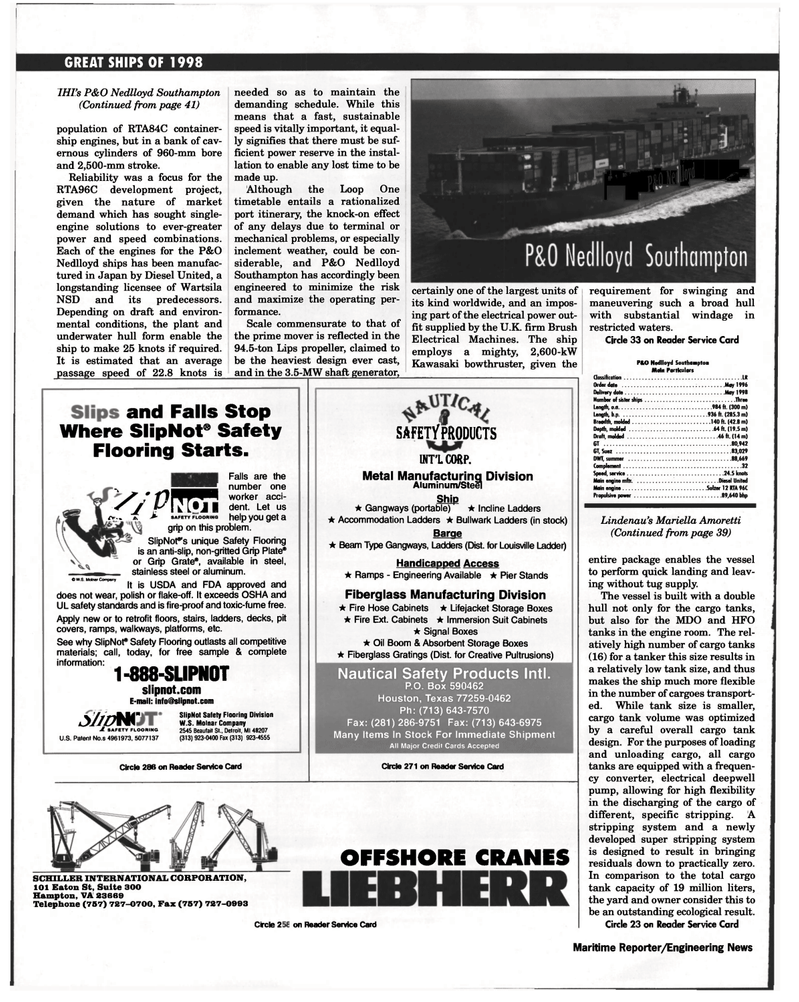

Pto Nedlloyd Southampton

Main Particulars

Classification LR

Order date May 1996

Delivery dote y 1998

Number of sister ships Three

Length, o.a 984 ft. (300 ml

Length, b.p 936 ft. (285.3 m)

Breadth, molded 140 ft. (42.8 m)

Depth, molded 64 ft. (19.5 m)

Draft, molded 46 ft. (14 m)

GT 80,942

GT, Suez 83,029

DWT, summer 88,66

Complement 32

Speed, service 24.5 knots

Main engine mftr. Diesel United

Main engine Sulzer 12 KTA 96C

Propulsive power 89,640 bhp

Lindenau's Mariella Amoretti (Continued from page 39) entire package enables the vessel to perform quick landing and leav- ing without tug supply.

The vessel is built with a double hull not only for the cargo tanks, but also for the MDO and HFO tanks in the engine room. The rel- atively high number of cargo tanks (16) for a tanker this size results in a relatively low tank size, and thus makes the ship much more flexible in the number of cargoes transport- ed. While tank size is smaller, cargo tank volume was optimized by a careful overall cargo tank design. For the purposes of loading and unloading cargo, all cargo tanks are equipped with a frequen- cy converter, electrical deepwell pump, allowing for high flexibility in the discharging of the cargo of different, specific stripping. A stripping system and a newly developed super stripping system is designed to result in bringing residuals down to practically zero.

In comparison to the total cargo tank capacity of 19 million liters, the yard and owner consider this to be an outstanding ecological result.

Circle 23 on Reader Service Card 54 Maritime Reporter/Engineering News

51

51

53

53