Page 60: of Maritime Reporter Magazine (December 1998)

Read this page in Pdf, Flash or Html5 edition of December 1998 Maritime Reporter Magazine

GREAT SHIPS OF 1998

Fincantieri Cantieri

Navali Italian? S.p.A

Tor Selandia

RoRo freight ship

Tor Line AB, Sweden

Shipbuilder

Vessel name

Vessel Type

Owner/ operator

Marking its first newbuild pro- ject in two decades, Tor Line's new generation of RoRo freight vessels molds its extensive experience in the tough North Sea trades with an understanding of the changing transportation requirements of industry and commerce.

Tor Selandia heralds faster transits, higher unit capacity, sys- tem-shipping efficiency and signif- icantly greater route productivity on the company's AngloBridge operation between Sweden and the

U.K. But considerations of year- round service dependability and freight delivery in pristine condi- tion, and logistical planning matching just-in-time shipping and distribution practices, have complemented the advances in size and speed.

All three Tor Selandia-class ves- sels, entrusted to Fincantieri's

Ancona yard in the Adriatic, are to be phased into AngloBridge, to cut crossing times between

Gothenburg and Immingham from 34 to 24 hours, and reduce port turnarounds from around 10-12 hours to six hours.

Ranking among the highest capacity ships deployed on the

North Sea, Tor Selandia provides for 2,820 lane meters of rolling freight, equating to approximately 200 trailers. She has been config- ured and dimensioned for a sub- stantial traffic mix, comprising rolltrailers and special cassettes, as well as road trailers, containers and trade vehicles. The 640 ft. (195 m) class has been built to the broadest width possible for pas- sage through the lock into

Immingham Dock, a prominent

U.K. interface for trade on indus- trial South Humberside.

Industrial shipping provides baseload business for the

AngloBridge operation, including inter-plant transfers between

Avesta steelmaking facilities in

Sweden and the U.K., and a con- tract of affreightment with

Swedish producer Stora covering shipments of newsprint, paper reels and other products.

Turnaround performance bene- fits from the obstruction-free main garage deck and Kvaerner Ships

Equipment-designed cargo access and internal transfer arrange- ments, plus the adoption of a new trestle-based lashing system adopted throughout the cargo sec- tion. The arrangements involve a structure incorporating a recessed fifth wheel which couples directly to the trailer's kingpin, while the trestle is automatically clamped to the deck using four twistlock con- nections. Two web lashings are applied at the rear of the trailer to secure the unit against any move- ment at sea.

Although Tor Selandia has become one of the fastest RoRo freight ships on the North Sea, the operator's concern with sustain- able speed performance through the year, given the difficult and extreme conditions often presented by that body of water, matched the requirement for more rapid

Lindenau s Hornisse (Continued from page 49) approximate 5,000-cu. m of segre- gated ballast space is protected by an epoxy coating.

Due account has been taken of future regulations governing mini- mum stability during cargo load- ing and discharge in the design of

Buttner's new vessel The main engine was designed and manufac- tured at the nearby Kiel works of

MaK Motoren, a Caterpillar Group business unit focused on the medi- um-speed marine business.

The nine-cylinder plant employs the highly-regarded M32 design, which turns out 4,200-kW at a crankshaft speed of 600-rpm.

Drive through Renk transmission reduces the rotational speed at the

Lips controllable pitch propeller to 116-rpm, in a system which has added utility for its incorporation of a pto (power take-off) for a shaft generator running at 1,500-rpm.

Reflecting her operating ambit, with a pronounced need for maneuverability in restricted waters and at tight berths,

Hornisse is fitted with a high-effi- ciency, semi-spade rudder, and an electrically-driven, 550-kW Lips bowthruster.

Circle 35 on Reader Service Card

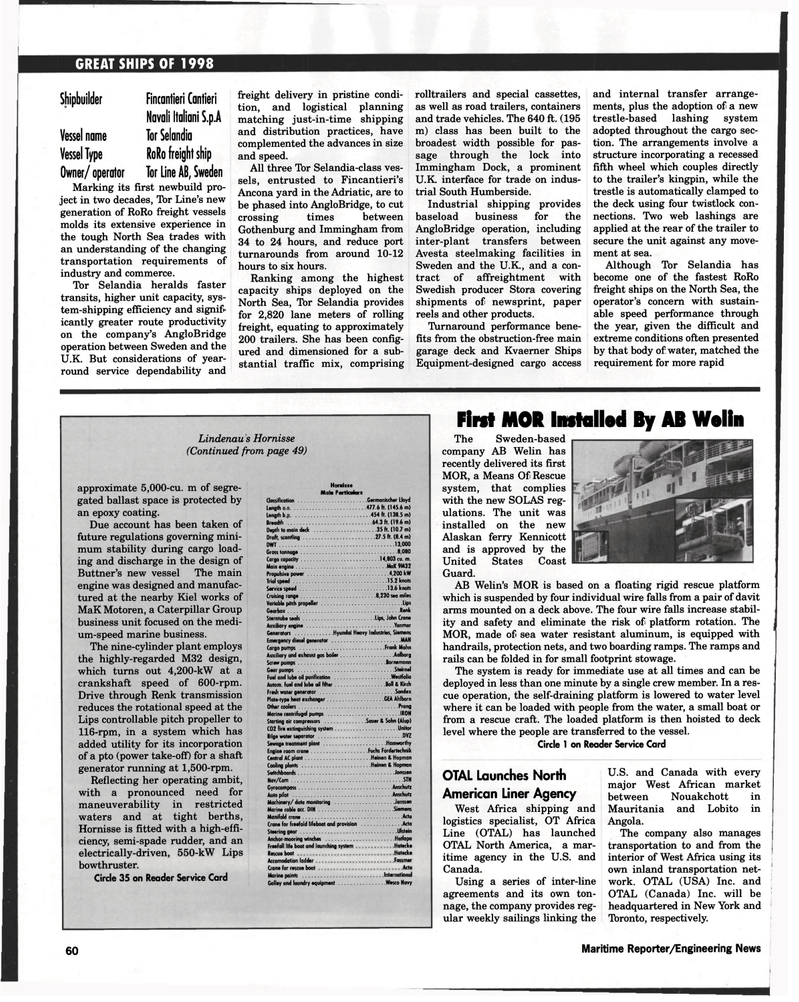

Hornisse

Main Partkutars

Classification Germanischer Lloyd length o.a 477.6 ft. (145.6 m)

Length b.p 454 ft. (138.5 ml

Breadth 64.3 ft (19.6 m)

Depth to main deck 35 ft. (10.7 m)

Draft, standing 27.5 ft. (8.4 m)

DWT 13,000

Gross tonnage 8,08

Cargo capacity 14,803 cu. m.

Main engine MaK 9M32

Propulsive power 4,200 kW

Trial speed 15.2 knots

Service speed 13.6 knots

Cruising range 8,230 sea miles

Variable pitch propeller lip

Gearbox Renk

Sterntube seals lips, John Crane

Auxiliary engine Yanmar

Generators Hyundai Heavy Industries, Siemens

Emergency diesel generator MAN

Cargo pumps Frank Mohn

Auxiliary and exhaust gas boiler Aalborg

Screw pumps Bornemon

Gear pumps Steirnel

Fuel and lube oil purification Westfolia

Autom. fuel and lube ail filler Boll & Kirch

Fresh water generator Sondex

Plate-type heat exchanger GEA Ahlborn

Other coolers Prang

Marine centrifugal pumps IRON

Starting air compressors Sauer & Sohn (Alup)

C02 fire extinguishing system Unitor

Bilge water separator DVZ

Sewage treatment plant Hamworthy

Engine room crane Fuchs Fordertechnik

Central AC plant Heinen & Hopman

Cooling plants Heinen & Hopman

Switchboards Jonsse

Nav/Com SIN

Gyrocompass Anschutz

Autopilot Anschut

Machinery/ data monitoring Janssen

Marine cable occ. DIN Siemens

Manifold crane Acta

Crane for freefold lifeboat and provision Act

Steering gear Ulstein

Anchor-mooring winches Hatlopa

Freefall life boat and launching system Hatecke

Rescue boat Hateck

Accomodation ladder Fassmer

Crane for rescue boot Acta

Marine paints International

Galley and laundry equipment Wesco Navy

First MOR Installed By AB Welin

The Sweden-based company AB Welin has recently delivered its first

MOR, a Means Of Rescue system, that complies with the new SOLAS reg- ulations. The unit was installed on the new

Alaskan ferry Kennicott and is approved by the

United States Coast

Guard.

AB Welin's MOR is based on a floating rigid rescue platform which is suspended by four individual wire falls from a pair of davit arms mounted on a deck above. The four wire falls increase stabil- ity and safety and eliminate the risk of platform rotation. The

MOR, made of sea water resistant aluminum, is equipped with handrails, protection nets, and two boarding ramps. The ramps and rails can be folded in for small footprint stowage.

The system is ready for immediate use at all times and can be deployed in less than one minute by a single crew member. In a res- cue operation, the self-draining platform is lowered to water level where it can be loaded with people from the water, a small boat or from a rescue craft. The loaded platform is then hoisted to deck level where the people are transferred to the vessel.

Circle 1 on Reader Service Card

OTAL Launches North

American Liner Agency

West Africa shipping and logistics specialist, OT Africa

Line (OTAL) has launched

OTAL North America, a mar- itime agency in the U.S. and

Canada.

Using a series of inter-line agreements and its own ton- nage, the company provides reg- ular weekly sailings linking the

U.S. and Canada with every major West African market between Nouakchott in

Mauritania and Lobito in

Angola.

The company also manages transportation to and from the interior of West Africa using its own inland transportation net- work. OTAL (USA) Inc. and

OTAL (Canada) Inc. will be headquartered in New York and

Toronto, respectively. 60 Maritime Reporter/Engineering News

59

59

61

61