Page 21: of Maritime Reporter Magazine (December 2003)

Grear Ships of 20003

Read this page in Pdf, Flash or Html5 edition of December 2003 Maritime Reporter Magazine

great ships of 2003

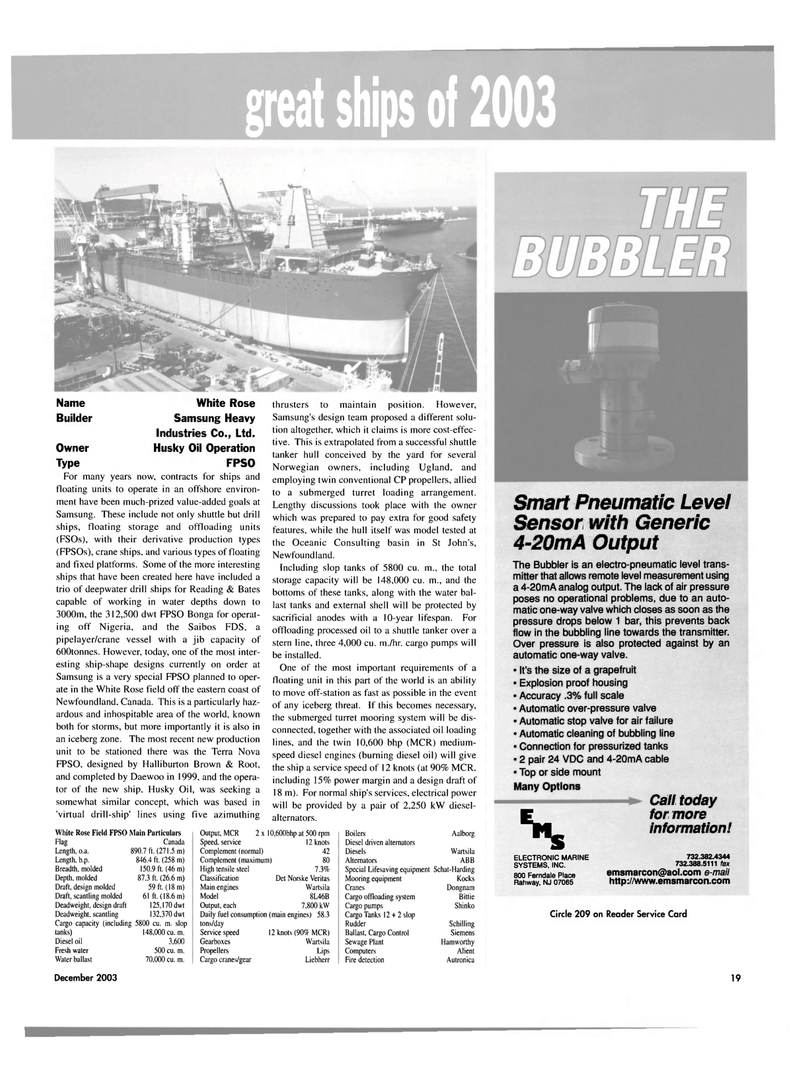

Name White Rose

Builder Samsung Heavy

Industries Co., Ltd.

Owner Husky Oil Operation

Type FPSO

For many years now, contracts for ships and floating units to operate in an offshore environ- ment have been much-prized value-added goals at

Samsung. These include not only shuttle but drill ships, floating storage and offloading units (FSOs), with their derivative production types (FPSOs), crane ships, and various types of floating and fixed platforms. Some of the more interesting ships that have been created here have included a trio of deepwater drill ships for Reading & Bates capable of working in water depths down to 3000m, the 312,500 dwt FPSO Bonga for operat- ing off Nigeria, and the Saibos FDS, a pipelayer/crane vessel with a jib capacity of 6()0tonnes. However, today, one of the most inter- esting ship-shape designs currently on order at

Samsung is a very special FPSO planned to oper- ate in the White Rose field off the eastern coast of

Newfoundland, Canada. This is a particularly haz- ardous and inhospitable area of the world, known both for storms, but more importantly it is also in an iceberg zone. The most recent new production unit to be stationed there was the Terra Nova

FPSO, designed by Halliburton Brown & Root, and completed by Daewoo in 1999, and the opera- tor of the new ship. Husky Oil, was seeking a somewhat similar concept, which was based in 'virtual drill-ship' lines using five azimuthing thrusters to maintain position. However,

Samsung's design team proposed a different solu- tion altogether, which it claims is more cost-effec- tive. This is extrapolated from a successful shuttle tanker hull conceived by the yard for several

Norwegian owners, including Ugland, and employing twin conventional CP propellers, allied to a submerged turret loading arrangement.

Lengthy discussions took place with the owner which was prepared to pay extra for good safety features, while the hull itself was model tested at the Oceanic Consulting basin in St John's,

Newfoundland.

Including slop tanks of 5800 cu. m., the total storage capacity will be 148,000 cu. m., and the bottoms of these tanks, along with the water bal- last tanks and external shell will be protected by sacrificial anodes with a 10-year lifespan. For offloading processed oil to a shuttle tanker over a stern line, three 4,000 cu. m./hr. cargo pumps will be installed.

One of the most important requirements of a floating unit in this part of the world is an ability to move off-station as fast as possible in the event of any iceberg threat. If this becomes necessary, the submerged turret mooring system will be dis- connected, together with the associated oil loading lines, and the twin 10,600 bhp (MCR) medium- speed diesel engines (burning diesel oil) will give the ship a service speed of 12 knots (at 90% MCR. including 15% power margin and a design draft of 18 m). For normal ship's services, electrical power will be provided by a pair of 2,250 kW diesel- alternators.

Smart Pneumatic Level

Sensor with Generic 4-20mA Output

The Bubbler is an electro-pneumatic level trans- mitter that allows remote level measurement using a 4-20mA analog output. The lack of air pressure poses no operational problems, due to an auto- matic one-way valve which closes as soon as the pressure drops below 1 bar, this prevents back flow in the bubbling line towards the transmitter.

Over pressure is also protected against by an automatic one-way valve. • It's the size of a grapefruit • Explosion proof housing • Accuracy .3% full scale • Automatic over-pressure valve • Automatic stop valve for air failure • Automatic cleaning of bubbling line • Connection for pressurized tanks • 2 pair 24 VDC and 4-20mA cable • Top or side mount

Many Options

White Rose Field FPSO Main Particulars

Flag Canada

Length, o.a. 890.7 ft. (271.5 m)

Length, b.p. 846.4 ft. (258 m)

Breadth, molded 150.9 ft. (46 m)

Depth, molded 87.3 ft. (26.6 m)

Draft, design molded 59 ft. (18 m)

Draft, scantling molded 61 ft. (18.6 m)

Deadweight, design draft 125,170 dwt

Deadweight, scantling 132,370 dwt

Cargo capacity (including 5800 cu. m. slop tanks) " 148,000 cu.m.

Diesel oil 3,600

Fresh water 500 cu. m.

Water ballast 70,000 cu.m.

Output, MCR 2 x10,600bhp at 500 rpm

Speed, service 12 knots

Complement (normal) 42

Complement (maximum) 80

High tensile steel 7.3%

Classification Det Norske Veritas

Main engines Wartsila

Model 8L46B

Output, each 7,800 kW

Daily fuel consumption (main engines) 58.3 tons/day

Service speed 12 knots (90% MCR)

Gearboxes Wartsila

Propellers Lips

Cargo cranes/gear Liebherr

Boilers

Diesel driven alternators

Diesels

Alternators

Special Lifesaving equipment

Mooring equipment

Cranes

Cargo offloading system

Cargo pumps

Cargo Tanks 12 + 2 slop

Rudder

Ballast, Cargo Control

Sewage Plant

Computers

Fire detection

Aalborg

Wartsila

ABB

Schat-Harding

Kocks

Dongnam

Bittie

Shinko

Schilling

Siemens

Hamworthy

Alient

Autronica

X

ELECTRONIC MARtNE

SYSTEMS, INC. 800 Ferndale Place

Rahway, NJ 07065

Call today for more information! 732.382.4344 732.388.5111 fax [email protected] e-mail http://www.emsmarcon.com

Circle 209 on Reader Service Card

December 2003 19

20

20

22

22