Page 60: of Maritime Reporter Magazine (June 2, 2010)

Read this page in Pdf, Flash or Html5 edition of June 2, 2010 Maritime Reporter Magazine

mately $765,000 on a roundtrip voyage, not including maneuvering and port op- erations. Our system will spend approxi- mately $655,000 on a similar voyage assuming 3% consumption of LNG, which results in a 14% savings of ap- proximately $110,000 per voyage. Over the course of the year, a ship with a sim- ilar operating profile would save about $1,250,000.

Our cost analysis confirms our expec- tation that money will be saved during transit by using a fuel cell system instead of a DFDE system. Capital costs for the fuel cell system will likely be much higher than those for a DFDE system, even when the technology is ready for its initial application. However, with such large savings in fuel costs, it may be pos- sible to recoup that cost and make the system more economically competitive.

If its lifetime cost can be within the range of that of a diesel, other advantages like environmental cleanliness could make it a very desirable option. Eventually, as further investment is made in this tech- nology, engineering advances and the benefits of mass production should radi- cally decrease the costs from their current values.

We would have liked to give an esti- mate of the cost of this system, so as to draw a more thorough analysis between it and existing ships. However, the technol- ogy is only just being applied commer- cially and many corporations closely guard data on costs. We have had diffi- culty obtaining any reasonable estimate for a system of this size, or for a compa- rable system that could be scaled for this application. However, we have estimated the net present value of the fuel savings over a 20 year life to be between $10.7 and $15.6 million. This is a significant amount of savings, a portion of which could be applied to the capital cost of the fuel cell system to offset any price differ- ence between it and a DFDE system.

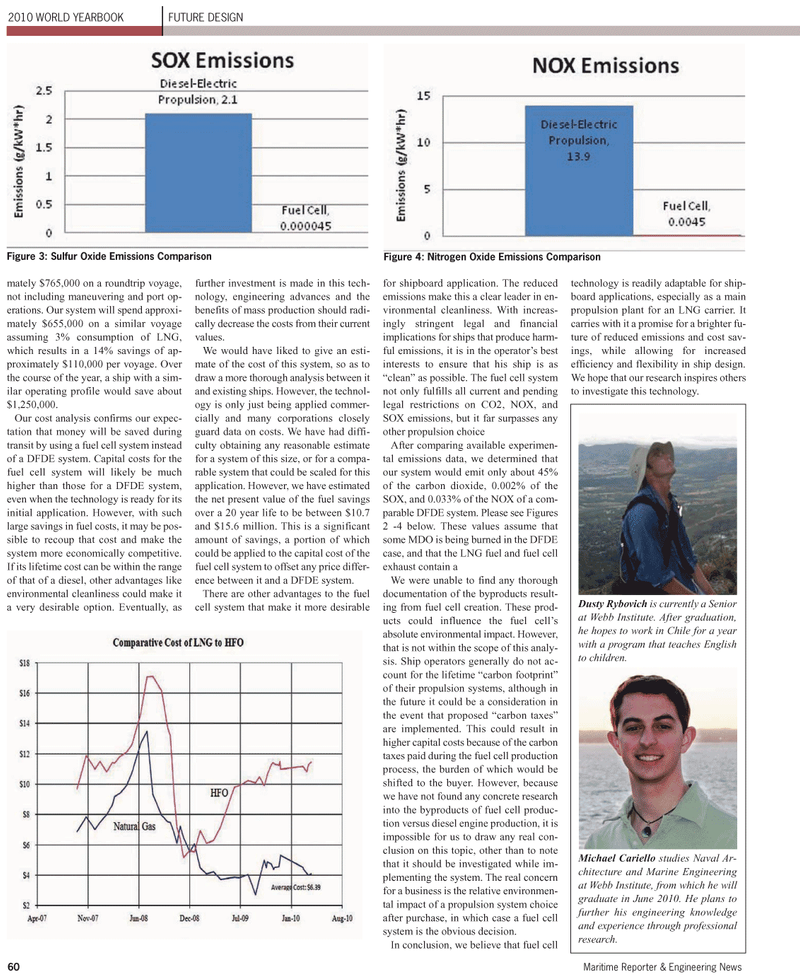

There are other advantages to the fuel cell system that make it more desirable for shipboard application. The reduced emissions make this a clear leader in en- vironmental cleanliness. With increas- ingly stringent legal and financial implications for ships that produce harm- ful emissions, it is in the operator’s best interests to ensure that his ship is as “clean” as possible. The fuel cell system not only fulfills all current and pending legal restrictions on CO2, NOX, and

SOX emissions, but it far surpasses any other propulsion choice

After comparing available experimen- tal emissions data, we determined that our system would emit only about 45% of the carbon dioxide, 0.002% of the

SOX, and 0.033% of the NOX of a com- parable DFDE system. Please see Figures 2 -4 below. These values assume that some MDO is being burned in the DFDE case, and that the LNG fuel and fuel cell exhaust contain a

We were unable to find any thorough documentation of the byproducts result- ing from fuel cell creation. These prod- ucts could influence the fuel cell’s absolute environmental impact. However, that is not within the scope of this analy- sis. Ship operators generally do not ac- count for the lifetime “carbon footprint” of their propulsion systems, although in the future it could be a consideration in the event that proposed “carbon taxes” are implemented. This could result in higher capital costs because of the carbon taxes paid during the fuel cell production process, the burden of which would be shifted to the buyer. However, because we have not found any concrete research into the byproducts of fuel cell produc- tion versus diesel engine production, it is impossible for us to draw any real con- clusion on this topic, other than to note that it should be investigated while im- plementing the system. The real concern for a business is the relative environmen- tal impact of a propulsion system choice after purchase, in which case a fuel cell system is the obvious decision.

In conclusion, we believe that fuel cell technology is readily adaptable for ship- board applications, especially as a main propulsion plant for an LNG carrier. It carries with it a promise for a brighter fu- ture of reduced emissions and cost sav- ings, while allowing for increased efficiency and flexibility in ship design.

We hope that our research inspires others to investigate this technology. 2010 WORLD YEARBOOK FUTURE DESIGN

Figure 3: Sulfur Oxide Emissions Comparison Figure 4: Nitrogen Oxide Emissions Comparison 60 Maritime Reporter & Engineering News

Dusty Rybovich is currently a Senior at Webb Institute. After graduation, he hopes to work in Chile for a year with a program that teaches English to children.

Michael Cariello studies Naval Ar- chitecture and Marine Engineering at Webb Institute, from which he will graduate in June 2010. He plans to further his engineering knowledge and experience through professional research.

59

59

61

61