Page 37: of Maritime Reporter Magazine (July 2014)

Offshore Energy Structures & Systems

Read this page in Pdf, Flash or Html5 edition of July 2014 Maritime Reporter Magazine

www.marinelink.com 37 annual natural gas demand that Shell estimates could be met by the facility’s annual LNG production. 1.6 million the number of engineering man hours invested into the front end engineering and design (FEED) phase of the development. 110,000 The number of natural gas equiva- lent 110,000 barrels of oil per day that Prelude will be capable of processing. 5,000 The number of workers who will build the

LNG facility. About 3,000 The number of engineering drawings done for the project. 3,000 km Total length of electrical and oth- er cabling installed on the facility, the distance from

Barcelona to Moscow. 600 The number of engineers worldwide that have worked on the development phase of the Prelude

FLNG project to defi ne, design and evaluate plans. 220 km Amount of piping used in the vessel. 6,700 hp The power of each of three thrusters lo- cated in the rear of the Prelude FLNG; only two will operate at any one time. -162° Celsius (-260°F) the temper- ature at which natural gas turns into liquid natural gas (LNG). 1/600th the factor by which a volume of natural gas shrinks when it is turned into LNG 200 km (125 miles) The distance from the Pre- lude fi eld in the Browse Basin to the nearest land. 7 The number of Prelude development wells. 4 The number of competitors particularly hot on

Prelude’s heels with their own FLNG plans, including

Petronas, ConocoPhillips, GDF Suez and Exxon- BHP. 20-25 years – The length of time Prelude is ex- pected to stay moored over the gas fi elds before head- ing to dry dock for updates and repairs.

Milestones

Key milestones, Royal Dutch Shell’s FLNG facility to date: January 2007 – Discovery of gas in Prelude well. March 2009 – Discovery of gas in Concerto well. July 2009 - Shell awards the contract for the design, con- struction and installation of multiple FLNG facilities over a period of up to 15 years to a consortium of Technip and

Samsung Heavy Industries, based upon Shell’s proprietary design. November 2010 – Environmental approval received for the project. May 20, 2011 - Prelude FLNG Project was announced as Shell takes Financial Investment Decision (FID) on the

Prelude project. September 9, 2011 - Fabrication of Prelude well heads, marking the fi rst ever steel cut for the Prelude Project. May 2012 - The fi rst steel cut for the turret. October 2012 – First steel cut for the hull. January 2013 – Cutting of fi rst steel for the the topsides. June 2013 - Construction started on the Prelude Darwin Onshore Supply Base. September 2013 - First Turret module shipped to Geoje. September 2013 - Development well drilling started. November 30, 2013 – Hull fl oated for the fi rst time.

Source: Shell Australia (U.S. Navy photo illustration cour tesy of Newpor t News Shipbuilding/Released)

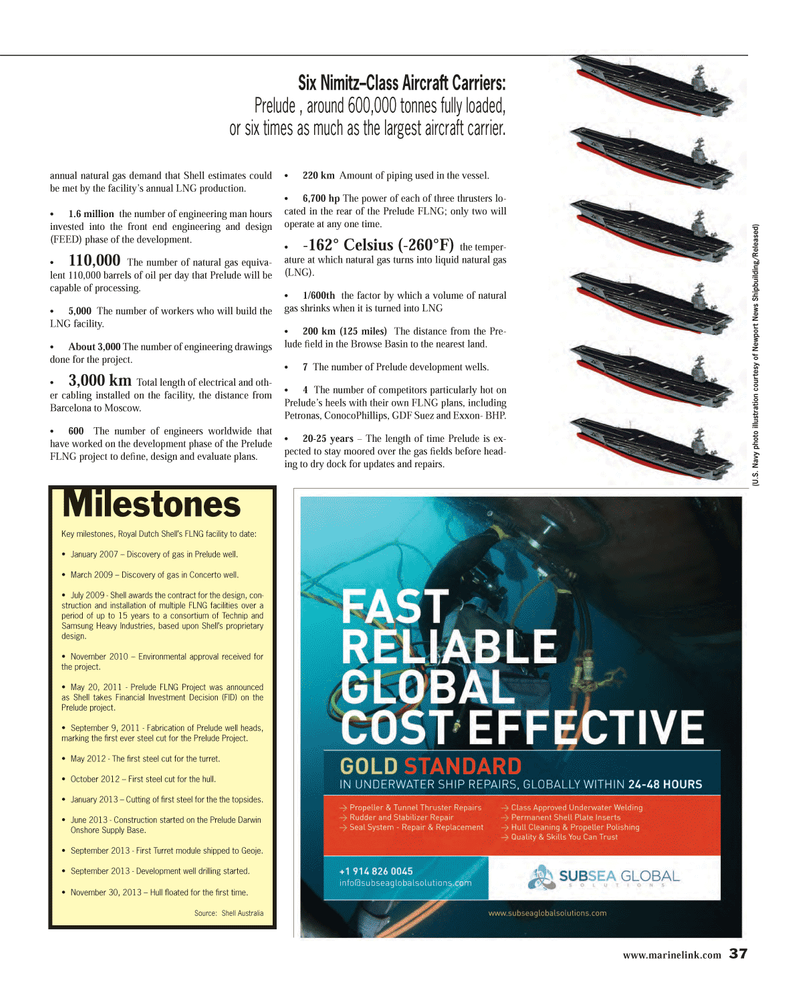

Six Nimitz–Class Aircraft Carriers:

Prelude , around 600,000 tonnes fully loaded, or six times as much as the largest aircraft carrier.

MR #7 (32-41).indd 37 7/1/2014 10:13:33 AM

36

36

38

38