Page 62: of Maritime Reporter Magazine (December 2015)

Great Ships of 2015

Read this page in Pdf, Flash or Html5 edition of December 2015 Maritime Reporter Magazine

TECH FILES

Next-Gen LNG Carrier Design

Image: DNV GL

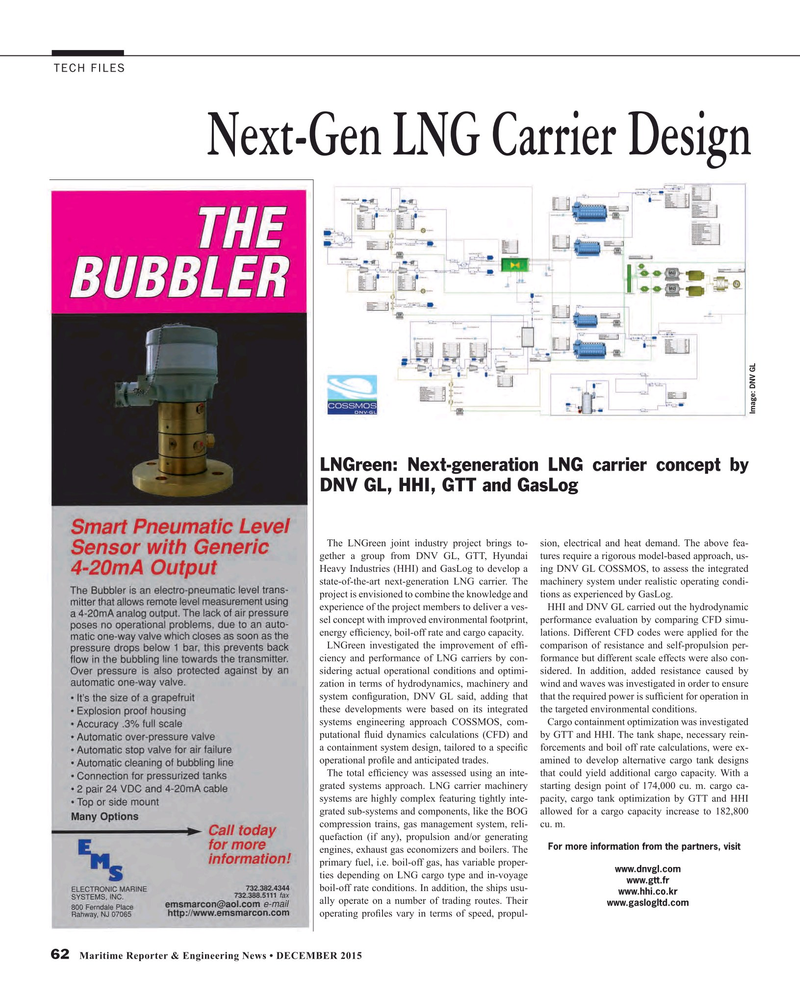

LNGreen: Next-generation LNG carrier concept by

DNV GL, HHI, GTT and GasLog

The LNGreen joint industry project brings to- sion, electrical and heat demand. The above fea- gether a group from DNV GL, GTT, Hyundai tures require a rigorous model-based approach, us-

Heavy Industries (HHI) and GasLog to develop a ing DNV GL COSSMOS, to assess the integrated state-of-the-art next-generation LNG carrier. The machinery system under realistic operating condi- project is envisioned to combine the knowledge and tions as experienced by GasLog.

experience of the project members to deliver a ves- HHI and DNV GL carried out the hydrodynamic sel concept with improved environmental footprint, performance evaluation by comparing CFD simu- energy ef? ciency, boil-off rate and cargo capacity. lations. Different CFD codes were applied for the

LNGreen investigated the improvement of ef? - comparison of resistance and self-propulsion per- ciency and performance of LNG carriers by con- formance but different scale effects were also con- sidering actual operational conditions and optimi- sidered. In addition, added resistance caused by zation in terms of hydrodynamics, machinery and wind and waves was investigated in order to ensure system con? guration, DNV GL said, adding that that the required power is suf? cient for operation in these developments were based on its integrated the targeted environmental conditions.

systems engineering approach COSSMOS, com- Cargo containment optimization was investigated putational ? uid dynamics calculations (CFD) and by GTT and HHI. The tank shape, necessary rein- a containment system design, tailored to a speci? c forcements and boil off rate calculations, were ex- operational pro? le and anticipated trades. amined to develop alternative cargo tank designs

The total ef? ciency was assessed using an inte- that could yield additional cargo capacity. With a grated systems approach. LNG carrier machinery starting design point of 174,000 cu. m. cargo ca- systems are highly complex featuring tightly inte- pacity, cargo tank optimization by GTT and HHI grated sub-systems and components, like the BOG allowed for a cargo capacity increase to 182,800 compression trains, gas management system, reli- cu. m.

quefaction (if any), propulsion and/or generating

For more information from the partners, visit engines, exhaust gas economizers and boilers. The primary fuel, i.e. boil-off gas, has variable proper- www.dnvgl.com ties depending on LNG cargo type and in-voyage www.gtt.fr boil-off rate conditions. In addition, the ships usu- www.hhi.co.kr ally operate on a number of trading routes. Their www.gaslogltd.com operating pro? les vary in terms of speed, propul- 62 Maritime Reporter & Engineering News • DECEMBER 2015

MR #12 (58-65).indd 62 12/4/2015 2:15:27 PM

61

61

63

63