Page 23: of Maritime Reporter Magazine (April 2016)

The Offshore Annual

Read this page in Pdf, Flash or Html5 edition of April 2016 Maritime Reporter Magazine

Figure 5

D?uO&?YÐOŽYs?ÐuA?

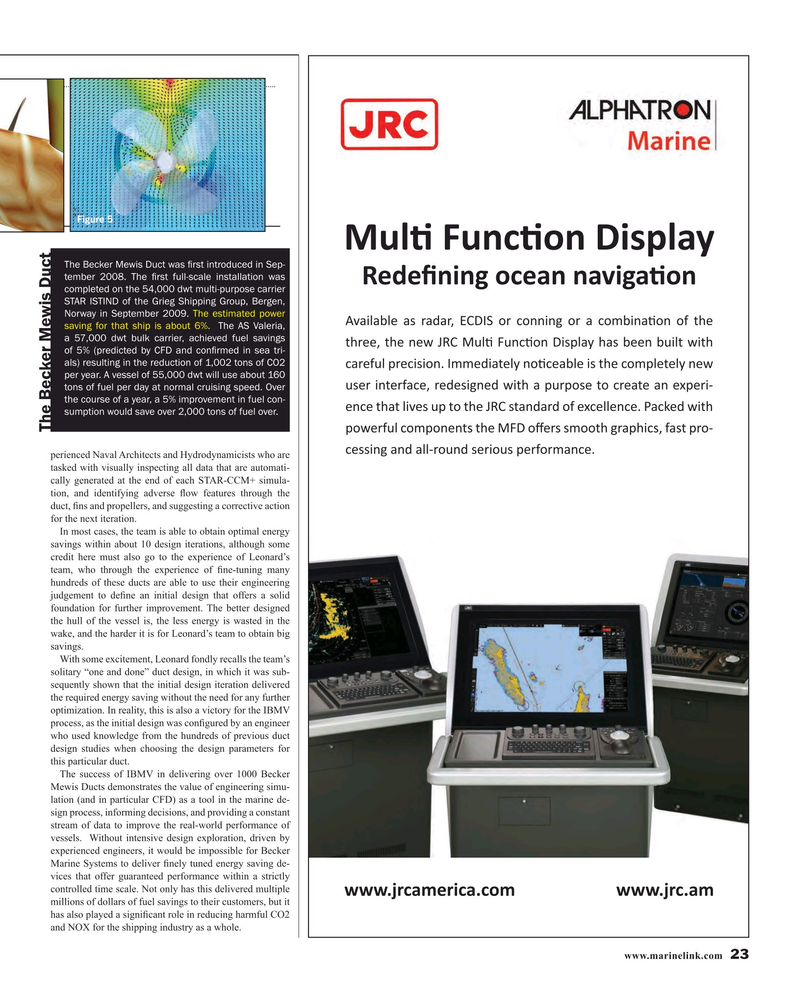

The Becker Mewis Duct was ? rst introduced in Sep- tember 2008. The ? rst full-scale installation was

ZGEGIYsYOŽÐGAYYA|sOAOŽY completed on the 54,000 dwt multi-purpose carrier

STAR ISTIND of the Grieg Shipping Group, Bergen,

Norway in September 2009. The estimated power |AsuAduGA??AEA??/^Ž?ÐŽYYsYOŽ?AÐŽwdsYAOŽYŽIlSG saving for that ship is about 6%. The AS Valeria, a 57,000 dwt bulk carrier, achieved fuel savings lS?GG?lSGYG?:ZD?uO&?YÐOŽYs?ÐuA?SA?dGGYd?sul?slS of 5% (predicted by CFD and con? rmed in sea tri- als) resulting in the reduction of 1,002 tons of CO2

ÐA?GI?uÐ?GÐs?sŽY?/wwGEsAlGu?YŽOÐGAduGs?lSGÐŽwÐuGlGu?YG?

per year. A vessel of 55,000 dwt will use about 160 ??G?sYlG?IAÐG??GEG?sOYGE?slSAÐ??ÐŽ?GlŽÐ?GAlGAYG?ÐG?s- tons of fuel per day at normal cruising speed. Over the course of a year, a 5% improvement in fuel con-

GYÐGlSAlus|G??ÐlŽlSG:Z?lAYEA?EŽIG?ÐGuuGYÐG?WAÐUGE?slS sumption would save over 2,000 tons of fuel over.

The Becker Mewis Duct

ÐŽ?G?I?uÐŽwÐŽYGYl?lSGD&ŽiG???wŽŽlSO?AÐSsÐ??IA?lÐ?Ž-

ÐG??sYOAYEAuu??Ž?YE?G?sŽ??ÐG?IŽ?wAYÐG?

perienced Naval Architects and Hydrodynamicists who are tasked with visually inspecting all data that are automati- cally generated at the end of each STAR-CCM+ simula- tion, and identifying adverse ? ow features through the duct, ? ns and propellers, and suggesting a corrective action for the next iteration.

In most cases, the team is able to obtain optimal energy savings within about 10 design iterations, although some credit here must also go to the experience of Leonard’s team, who through the experience of ? ne-tuning many hundreds of these ducts are able to use their engineering judgement to de? ne an initial design that offers a solid foundation for further improvement. The better designed the hull of the vessel is, the less energy is wasted in the wake, and the harder it is for Leonard’s team to obtain big savings.

With some excitement, Leonard fondly recalls the team’s solitary “one and done” duct design, in which it was sub- sequently shown that the initial design iteration delivered the required energy saving without the need for any further optimization. In reality, this is also a victory for the IBMV process, as the initial design was con? gured by an engineer who used knowledge from the hundreds of previous duct design studies when choosing the design parameters for this particular duct.

The success of IBMV in delivering over 1000 Becker

Mewis Ducts demonstrates the value of engineering simu- lation (and in particular CFD) as a tool in the marine de- sign process, informing decisions, and providing a constant stream of data to improve the real-world performance of vessels. Without intensive design exploration, driven by experienced engineers, it would be impossible for Becker

Marine Systems to deliver ? nely tuned energy saving de- vices that offer guaranteed performance within a strictly controlled time scale. Not only has this delivered multiple www.jrcamerica.com www.jrc.am millions of dollars of fuel savings to their customers, but it has also played a signi? cant role in reducing harmful CO2 and NOX for the shipping industry as a whole.

www.marinelink.com 23

MR #4 (18-25).indd 23 4/6/2016 5:30:15 PM

22

22

24

24