Page 100: of Maritime Reporter Magazine (November 2016)

Workboat Edition

Read this page in Pdf, Flash or Html5 edition of November 2016 Maritime Reporter Magazine

FEA Based Corrosion Processing

COATINGS

To Minimize Steel Renewal

BY FRITZ WALDORF & ARNOLD BALSTER very FPSO and FSO vessel ing structures. The method and software scantlings under their substantial corro- will reach a point in its life- tools within SAGA have been developed sion level or rule renewal values.

About the Authors cycle where there is a need for for the processing of standard gauging With a good representation of the cur-

Fritz Waldorf (pictured) is Director

Econducting corrosion analysis. reports to identify and visualize the loca- rent scantlings throughout the hull struc- of Sales and Marketing for Viking

Obvious reasons for such analysis are tion as well as the extent and severity of ture, the assessment for decision of what

Systems International and based in for life-extension purposes, as well as excessive corrosion. The structural pro- can be done to minimize the required their Houston of? ce. Viking assists protecting the feasibility and class ap- cessing and optimization process is used steel renewal for the client begins. shipyards, ship designers and owner/ proval of the hull structure. Such work to minimize the extent of any required Starting with class software operating operators with the ef? cient implemen- can be conducted on both new builds as steel renewal, proving extreme savings within the SAGA program suite, Viking tation of advanced analysis tools for well as conversions, especially when the in expense. identi? es the minimum rule scantlings ? oating vessels and structures.

work done at conversion was not exten- As many of these vessels are getting that satisfy both global strength and lo- sive enough. The distressed oil prices older and far enough into their design cal scantling requirements. Viking then

Arnold Balster is an Engineering Man- our current market presents, requires life or even into extension, Viking Sys- works through a FEA based strength and ager for Viking Systems International. vessel owners and operators to focus on tems is focusing on corrosion processing fatigue veri? cation process ensuring that

Arnold is based in Viking’s Houston ef? ciency in every aspect of their opera- and is ? nding instances in which corro- any scantling optimization done moving of? ce and has a naval architecture tions. SAGA, Viking System’s struc- sion is developing at a faster rate than forward is not invalidating the structural and hull structural background and tural assessment software, consists of a originally expected (for various reasons assessment and fatigue life-predictions together with his team is responsible for conducting the various engineering highly specialized 3D modeling tool that while in operation). In many cases, Vi- performed at construction. and design tasks.

has assisted in confronting the issue of king is receiving special report surveys At the point of satisfaction with a bal- corrosion and asset integrity for ? oat- back from the unit in operation with ance between minimum scantlings and structural integrity, the reassessed scant- lings are then placed back through our corrosion processing program within

SAGA, calculating the new scantlings at substantial corrosion while revising the steel renewal plans to re? ect the new op- timized scantlings.

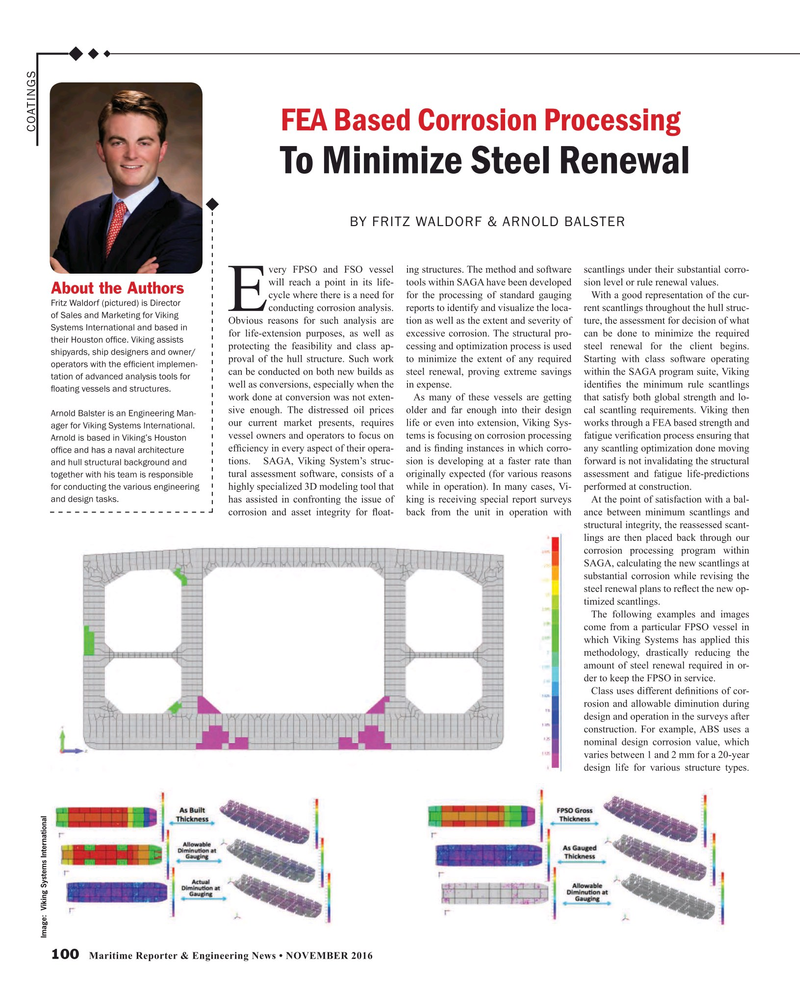

The following examples and images come from a particular FPSO vessel in which Viking Systems has applied this methodology, drastically reducing the amount of steel renewal required in or- der to keep the FPSO in service.

Class uses different de? nitions of cor- rosion and allowable diminution during design and operation in the surveys after construction. For example, ABS uses a nominal design corrosion value, which varies between 1 and 2 mm for a 20-year design life for various structure types.

Image: Viking Systems International 100 Maritime Reporter & Engineering News • NOVEMBER 2016

MR #11 (98-105).indd 100 11/4/2016 1:43:18 PM

99

99

101

101