Page 42: of Maritime Reporter Magazine (March 2017)

U.S. Navy Quarterly & Maritime Simulation Technologies

Read this page in Pdf, Flash or Html5 edition of March 2017 Maritime Reporter Magazine

Green Marine Case Study: 18-day Exhaust Gas Scrubber Installation oltens was contracted by a Planning and Preparation shop and ship the prefabricated material 22 hours. Goltens ran two shifts with a large cruise vessel owner to First, technical specialists inspected to the vessel in anticipation of its arrival minimum of two supervisors per shift to undertake the installation of the ship to evaluate the project, deter- in dry dock. ensure that quality controls and safety two exhaust gas scrubbers mine space requirements and record standards were adhered to throughout

G on one of its ships to comply with sul- any logistical obstacles. In addition, Phased Approach the project.

fur emissions regulations. The vessel 3D laser scanning of the spaces for the A ten-man crew performed the de- is powered by four GMT/Sulzer 16ZA- scrubbers was undertaken to facilitate molition work and prepared the engine On-time Completion

V40S and two GMT/Sulzer 12ZAV40S system modelling. This enabled Goltens casings for the rigging and installation Goltens worked closely with the ves- diesel electric generating sets. to complete the detailed design of the operations, with all preparatory work be- sel’s technical project management to

The project involved the evaluation, exhaust gas cleaning systems and map ing completed during a nine-day under- overcome any schedule delays caused planning, design and installation of out a de? nitive process, including plans way period prior to docking. Once in dry by weather and any technical obstacles two 10+ meter long exhaust gas scrub- for manning the project and determining dock, a team of more than 40 technicians encountered. As a result, the project was ber towers on Diesel Generators #1 and timelines for the removal of the existing and technical managers was mobilized completed a day ahead of schedule and #2 with a deadline to complete the op- exhaust silencers and installation of the to complete the project within the ten- the vessel was able to leave dry dock as eration before the end of the vessel’s dry new exhaust gas scrubbers within dead- day dry-docking period. The team re- planned. As a result, the company was dock period in a U.S. port. line. Goltens was also able to prefabri- moved all eight exhaust silencers and in- awarded and completed a similar con- cate foundation structures in its work- stalled all scrubber tower sections within tract on a sister vessel a few months later.

1 23

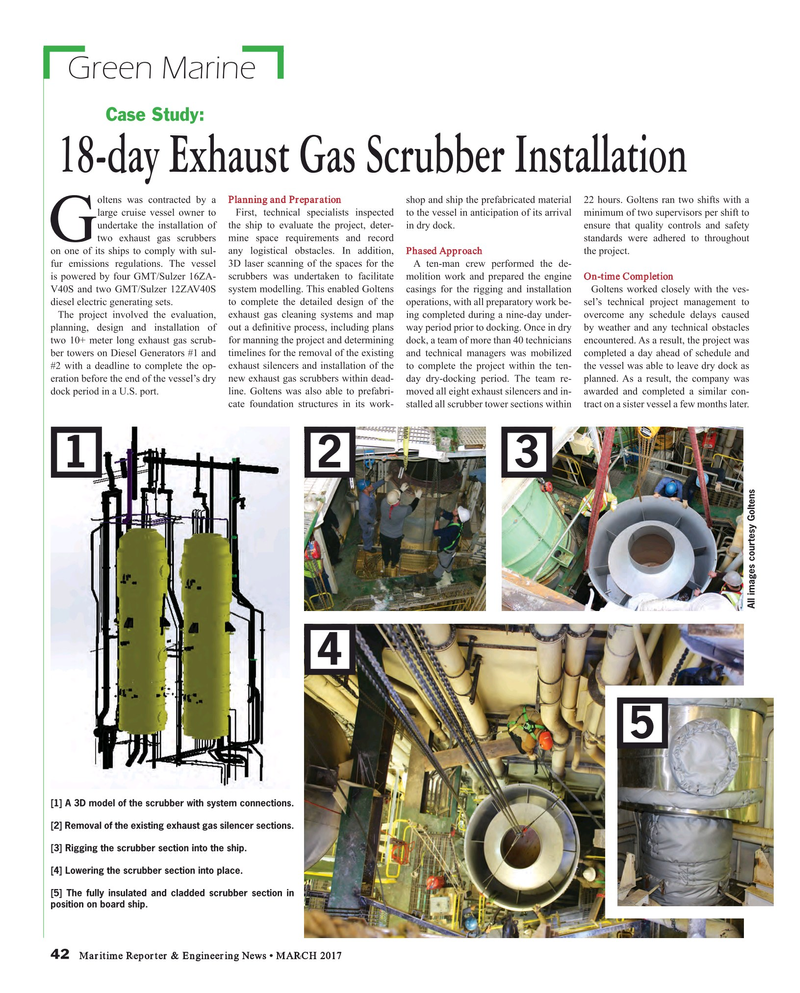

All images courtesy Goltens 4 5 [1] A 3D model of the scrubber with system connections. [2] Removal of the existing exhaust gas silencer sections. [3] Rigging the scrubber section into the ship. [4] Lowering the scrubber section into place. [5] The fully insulated and cladded scrubber section in position on board ship. 42 Maritime Reporter & Engineering News • MARCH 2017

MR #3 (42-49).indd 42 MR #3 (42-49).indd 42 3/6/2017 11:40:34 AM3/6/2017 11:40:34 AM

41

41

43

43