Page 79: of Maritime Reporter Magazine (October 2018)

Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2018 Maritime Reporter Magazine

COATINGS & CORROSION CONTROL

UV-C

Keeping Ship Hulls Biofouling Free

By Niek Hijnen, Technologist, Coatings Technology, AkzoNobel Coatings; & Michel Jongerius, Senior Scientist, Philips Research, Royal Philips

The presence of biofouling on the approach to traditional paints used in offered by the current paint systems. The UV-C is emitted from UV-LEDs, hull of a ship increases the drag from biofouling control on ship hulls. It uses This is the case both when the ship is which are embedded in a silicone light- the water during sailing and thereby an ultraviolet-C (UV-C) emitting layer sailing and when it is docked. Station- guide that helps in distributing the ir- the fuel consumption, which results in applied on the underwater areas of the ary prototype tiles have been tested radiation across the surface. Prototypes increased CO2 emissions as well as in- hull to keep the surface clean from foul- around the world and have been shown are currently tiles of 30x30cm2 with creased costs for the ship owner. Paints ing. The UV-C irradiation inactivates or capable to remain clean in various lo- a thickness of 10mm, and they have a applied to the underwater areas on the kills microorganisms through absorp- cations that are known to pose a high cable hardwired in for powering. To op- hull of ships therefore often contain tion by their DNA, a property regularly fouling challenge, like Singapore and timize the area kept clean by the indi- biocides to hinder biofouling growth or applied in water and air puri? cation the Great Barrier Reef in Australia. In vidual LEDs, they are con? gured such possess non-stick properties, allowing a systems, preventing the attachment and addition to reducing CO2 emissions by that they emit sideways into the plane. release of the fouling when the vessels growth of biofouling. offering unparalleled antifouling per- A portion of the emitted light is guided pick up speed. This new approach has demonstrated formance, the technology is a biocide- along the surface by the light-guide,

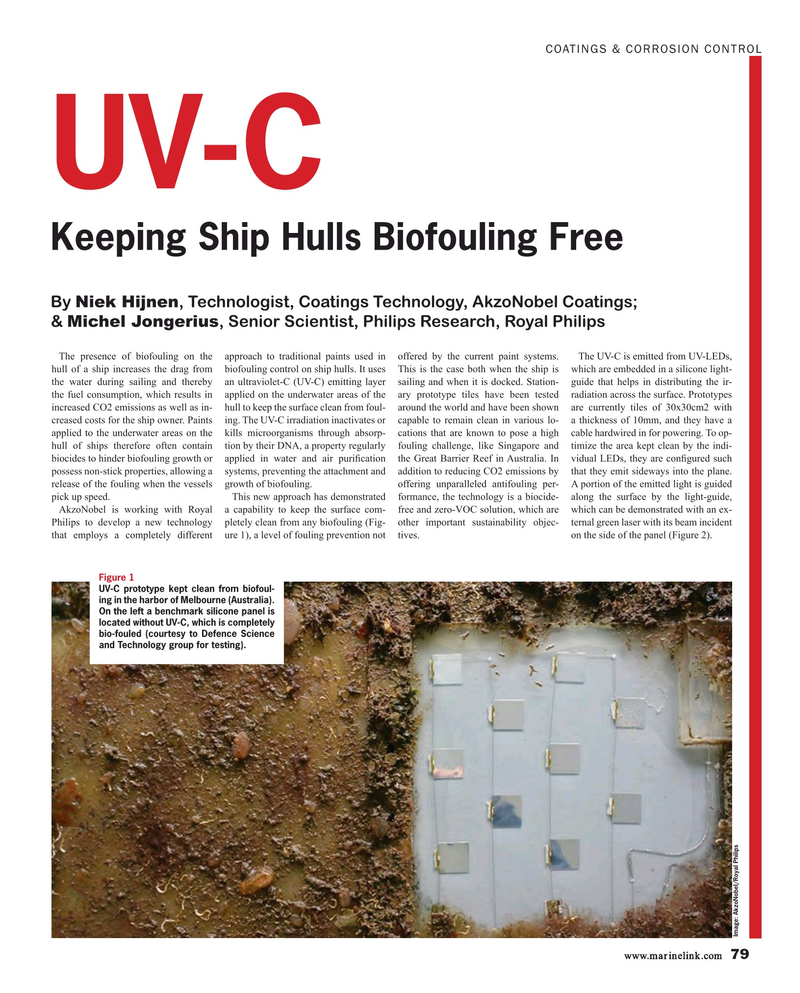

AkzoNobel is working with Royal a capability to keep the surface com- free and zero-VOC solution, which are which can be demonstrated with an ex-

Philips to develop a new technology pletely clean from any biofouling (Fig- other important sustainability objec- ternal green laser with its beam incident that employs a completely different ure 1), a level of fouling prevention not tives. on the side of the panel (Figure 2).

Figure 1

UV-C prototype kept clean from biofoul- ing in the harbor of Melbourne (Australia).

On the left a benchmark silicone panel is located without UV-C, which is completely bio-fouled (courtesy to Defence Science and Technology group for testing).

Image: AkzoNobel/Royal Philips www.marinelink.com 79

MR #10 (74-81).indd 79 MR #10 (74-81).indd 79 10/5/2018 11:19:57 AM10/5/2018 11:19:57 AM

78

78

80

80