Page 80: of Maritime Reporter Magazine (October 2018)

Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2018 Maritime Reporter Magazine

COATINGS & CORROSION CONTROL

Figure 2 (right)

Schematic illustration of the working principle of the UV-C concept. On the right, the principle of waveguiding in a test panel is demonstrated.

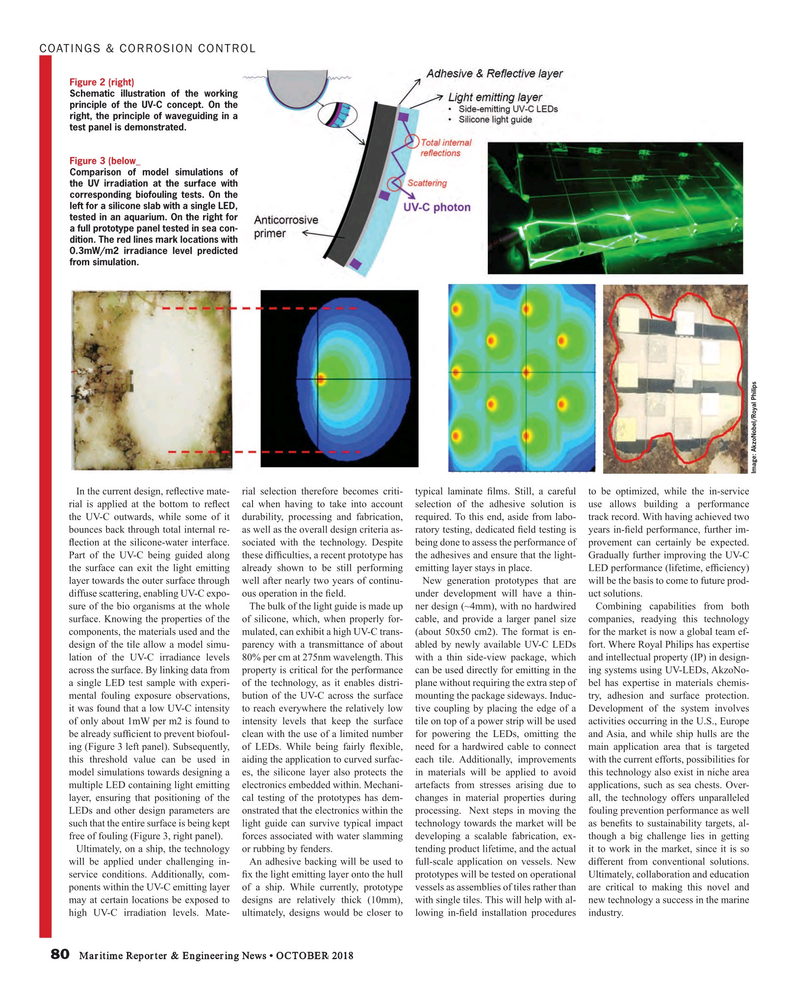

Figure 3 (below_

Comparison of model simulations of the UV irradiation at the surface with corresponding biofouling tests. On the left for a silicone slab with a single LED, tested in an aquarium. On the right for a full prototype panel tested in sea con- dition. The red lines mark locations with 0.3mW/m2 irradiance level predicted from simulation.

Image: AkzoNobel/Royal Philips

In the current design, re? ective mate- rial selection therefore becomes criti- typical laminate ? lms. Still, a careful to be optimized, while the in-service rial is applied at the bottom to re? ect cal when having to take into account selection of the adhesive solution is use allows building a performance the UV-C outwards, while some of it durability, processing and fabrication, required. To this end, aside from labo- track record. With having achieved two bounces back through total internal re- as well as the overall design criteria as- ratory testing, dedicated ? eld testing is years in-? eld performance, further im- ? ection at the silicone-water interface. sociated with the technology. Despite being done to assess the performance of provement can certainly be expected.

Part of the UV-C being guided along these dif? culties, a recent prototype has the adhesives and ensure that the light- Gradually further improving the UV-C the surface can exit the light emitting already shown to be still performing emitting layer stays in place. LED performance (lifetime, ef? ciency) layer towards the outer surface through well after nearly two years of continu- New generation prototypes that are will be the basis to come to future prod- diffuse scattering, enabling UV-C expo- ous operation in the ? eld. under development will have a thin- uct solutions. sure of the bio organisms at the whole The bulk of the light guide is made up ner design (~4mm), with no hardwired Combining capabilities from both surface. Knowing the properties of the of silicone, which, when properly for- cable, and provide a larger panel size companies, readying this technology components, the materials used and the mulated, can exhibit a high UV-C trans- (about 50x50 cm2). The format is en- for the market is now a global team ef- design of the tile allow a model simu- parency with a transmittance of about abled by newly available UV-C LEDs fort. Where Royal Philips has expertise lation of the UV-C irradiance levels 80% per cm at 275nm wavelength. This with a thin side-view package, which and intellectual property (IP) in design- across the surface. By linking data from property is critical for the performance can be used directly for emitting in the ing systems using UV-LEDs, AkzoNo- a single LED test sample with experi- of the technology, as it enables distri- plane without requiring the extra step of bel has expertise in materials chemis- mental fouling exposure observations, bution of the UV-C across the surface mounting the package sideways. Induc- try, adhesion and surface protection. it was found that a low UV-C intensity to reach everywhere the relatively low tive coupling by placing the edge of a Development of the system involves of only about 1mW per m2 is found to intensity levels that keep the surface tile on top of a power strip will be used activities occurring in the U.S., Europe be already suf? cient to prevent biofoul- clean with the use of a limited number for powering the LEDs, omitting the and Asia, and while ship hulls are the ing (Figure 3 left panel). Subsequently, of LEDs. While being fairly ? exible, need for a hardwired cable to connect main application area that is targeted this threshold value can be used in aiding the application to curved surfac- each tile. Additionally, improvements with the current efforts, possibilities for model simulations towards designing a es, the silicone layer also protects the in materials will be applied to avoid this technology also exist in niche area multiple LED containing light emitting electronics embedded within. Mechani- artefacts from stresses arising due to applications, such as sea chests. Over- layer, ensuring that positioning of the cal testing of the prototypes has dem- changes in material properties during all, the technology offers unparalleled

LEDs and other design parameters are onstrated that the electronics within the processing. Next steps in moving the fouling prevention performance as well such that the entire surface is being kept light guide can survive typical impact technology towards the market will be as bene? ts to sustainability targets, al- free of fouling (Figure 3, right panel). forces associated with water slamming developing a scalable fabrication, ex- though a big challenge lies in getting

Ultimately, on a ship, the technology or rubbing by fenders. tending product lifetime, and the actual it to work in the market, since it is so will be applied under challenging in- An adhesive backing will be used to full-scale application on vessels. New different from conventional solutions. service conditions. Additionally, com- ? x the light emitting layer onto the hull prototypes will be tested on operational Ultimately, collaboration and education ponents within the UV-C emitting layer of a ship. While currently, prototype vessels as assemblies of tiles rather than are critical to making this novel and may at certain locations be exposed to designs are relatively thick (10mm), with single tiles. This will help with al- new technology a success in the marine high UV-C irradiation levels. Mate- ultimately, designs would be closer to lowing in-? eld installation procedures industry.

80 Maritime Reporter & Engineering News • OCTOBER 2018

MR #10 (74-81).indd 80 MR #10 (74-81).indd 80 10/5/2018 11:20:39 AM10/5/2018 11:20:39 AM

79

79

81

81